Aluminum Die Cleaning Machine with High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

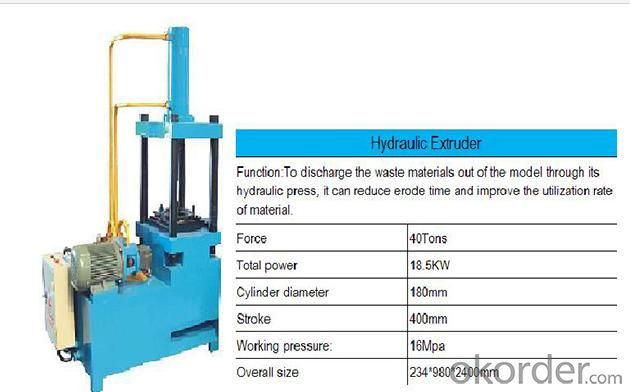

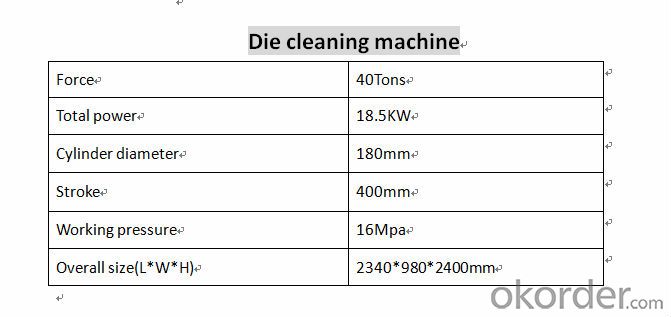

Die Cleaning Machine

1. The machine discharge the waste materials out of the extrusion die by the action of hydraulic pressure, reduce erode time and improve the usage rates of material.

2.The size can be designed and customized according to customers' requirements.

Technical parameters:

Packaging & Delivery

Packaging Details: Container

Delivery Detail: Within 40 days after received payment

Other Popular Products:

Aluminum Profile Extrusion Handling Table

Aluminum profile handling table is designed for the primary treatment after profile extruded, including the profiles' cooling, conveying, pulling, straightening, gauging and cutting. This equipment mostly for 500T-1800T aluminum extrusion press, adopt heat resistant felt belt and felt roller to convey, it can effectively avoid the profiles' secondary scraped and distorted, improve the product pass rate.

Aluminum Profile Packing Machine

The machine is designed for aluminum production packing, which is of good looking, easy operation, and low noise, good packing effect features.

Aluminum Billet Cutting Machine

The equipment can put a lot of billets on the storage table and continuously cut billets. It is mostly used in aluminium founding factory

Aluminum Profile Correction Machine

Aluminum Profile Film Sticking Machine

It has following feature: high taping speed, rigid taping effect and easy operation.The finished goods will has more competence after they are taped by this machine.

Aluminum Profile Finish Saw

The machine usually is working together with saw gauge table, it can be adjusted according to the length of extruded profiles;

Die Cleaning Machine

The machine discharge the waste materials out of the extrusion die by the action of hydraulic pressure, reduce erode time and improve the usage rates of material.

Aluminum Auto Stacker

1. The Auto stacker equip after the finish saw cutting, to storage the profile automatic;

2. Transfer many pieces of profile and the productive efficiency is high;

3. The entire productive line is controlled by computer so it is highly automatic

- Q: The role of food packaging machinery

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging. The main functions of packaging machinery are as follows:

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you have your own website here, through the optimization and promotion, to promote their products out, the customer concern, love content search, when people search through GG to see your home site, you may consult. There are many ways

- Q: What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q: Packaging machine knife cut out of the mouth is uneven, always inclined, so adjust, now tune not come back, or is unable to cut off, or die!

- Change a new one, in fact, the knife is very simple, and the ordinary knife is very cheap.If you don't understand, you can ask me

- Q: Color code positioning of packaging machinery

- Color code positioning and photoelectric trackingIn order to ensure the integrity of the mark on the finished package, it is usually printed on the package for positioning.

- Q: How is the production and characteristics of ceramic wall tiles different from the size and performance of molding?

- What is the size of the parison forming pressure and the performance of the ceramic wall and floor tile products?Ceramic wall and floor tiles are usually formed by pressing. Domestic made for 30 tons, imported equipment has tons of suppression, 200 tons and 500 tons. In order to smooth accurate size, excellent products, must pay attention to the effect of powder properties and compression of products. That is to say, the quality of the floor tiles, billets, methods of preparation, and the quality of products and production scale and way of pressing machinery. As for pressing pressure, as the molding pressure decreases, the sintering shrinkage becomes smaller and the water absorption rate becomes smaller, the durability of the product should be improved. It should be noted that the pressure should not be too high. Excessive pressure, stress, and density increase will cause unnecessary energy consumption, and cause compressed air to expand after pressure is canceled and cause excessive spalling.

- Q: What does that mean when the composite material is pressed and molded? What are pressing forming? What are the characteristics of press molding equipment? Its development

- Can be used to shape complex products. The principle is similar to that of injection molding. One is used for thermosetting, heating and cooling in molds, one for thermoplastic, and the other for heating in the barrel and molding cooling in the mold.

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Aluminum Die Cleaning Machine with High Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords