Aluminum 5052 Coil Price of 8011 and Aluminum Coil Manufacturer in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | Standard seaworthy packing for long distance transportation |

| Delivery Detail: | in 25-30 days upon the receipt of original L/C or 30% deposit |

Product Description

Specifications

Material | 1, 2, 3, 5, 6, 7, 8 Series |

Temper | O, F, H14, H34, H32, H112, T4, T6 |

Surface treatment | Mill Finish, Anodized, Electroplates, Powder Coated, Wooden Finish, Polished |

Color | Plain, Silver, Black, Red, Blue, or as required |

Length | 1000mm~6000mm, or as required |

Shape | Plain, bossed, or as per the drawings and samples |

Fabrication | Cutting, drilling, punching, bending, etc |

Tolerances | As per your requirements |

Package | inner plastic paper interleaving each piece profile, outer fixed by plywood; or customized. |

Payment terms | T/T or L/C at sight |

Price terms | FOB; CIF |

Delivery time | 15~20 days after order confirmation |

Certification | ISO 9001:2008; SGS |

Application | Decorations, Fence, Building, Aviation industry, Mechanical equipment |

Capacity | 5000 tons per month |

MOQ | 1 Metric ton

|

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Parameter

Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

Application:

1) Radiator

2) Condenser

3) Insulation Material

4) Construction

5) Decoration

6) Advertisement and market applications

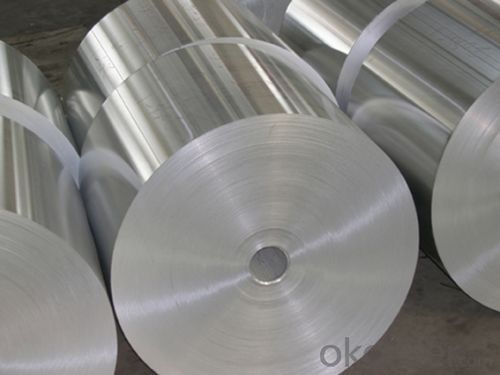

Photos

- Q: Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q: I have a school project due in a couple weeks and I need to make a life size sculpture of a camera. I don't want to make it solid because that would use a lot of clay and wouldn't evenly cook. Can I put something inside like aluminum foil?

- The aluminum will not allow the clay to shrink as it dries. The clay will crack. Also, the aluminum will melt around 1200* so you need to know how hot you will be firing the kiln. You should be able to make the camera body by the slab method and make a box and add the lens and knobs. This will give you a hollow body.

- Q: Can aluminum coils be used for seamless gutters?

- Yes, aluminum coils can be used for seamless gutters. Aluminum is a popular choice for seamless gutter installations due to its durability, lightweight nature, and resistance to corrosion. The coils can be easily shaped and formed to create a seamless gutter system that effectively directs rainwater away from the building.

- Q: How are aluminum coils used in electrical applications?

- Due to their advantageous properties, aluminum coils find wide application in various electrical uses. Transformers, motors, and inductors are the primary domains where these coils are employed. Transformers utilize aluminum coils to facilitate the transfer of electrical energy from one circuit to another. These coils are wrapped around a magnetic core, thereby facilitating efficient energy transfer. Aluminum coils are preferred over copper coils in transformers due to their affordability, light weight, and superior conductivity. Moreover, aluminum coils exhibit higher thermal conductivity, enabling better heat dissipation. This feature is crucial for maintaining transformer efficiency and longevity. In motors, aluminum coils serve as the winding material for the stator, which is the stationary component of the motor. By passing an electrical current through the coils, a magnetic field is generated. This magnetic field interacts with the rotating magnetic field produced by the motor's rotor, resulting in motor rotation. Aluminum coils are favored in motors due to their lightweight nature, contributing to overall motor efficiency by reducing its weight. Inductors, another electrical component, employ aluminum coils. Inductors store electrical energy in the form of a magnetic field. When an electric current traverses the coil, a magnetic field is generated, which opposes changes in the current. Aluminum coils are utilized in inductors owing to their high electrical conductivity, facilitating efficient energy storage and release. In summary, aluminum coils are extensively used in electrical applications due to their cost-effectiveness, lightweight nature, excellent conductivity, and high thermal conductivity. Their application in transformers, motors, and inductors plays a pivotal role in ensuring efficient and reliable operation of electrical systems.

- Q: ok me and my father are trying to make thermite. we have the iron oxide but the aluminum we only have paste and i was wondering would it work the same as if we had the powder.and if it is differnt will it work for the thermite and what will it take to light it.

- The aluminum paste may or may not work. It depends on what the solvent is that the aluminum is dissolved in. Why not get a block of aluminum and a grinder, and make your own aluminum dust?

- Q: Besides replacing all the aluminum wiring.

- First find out the Electrical Codes for your city or area. Some don't allow aluminum and you have to have it up to code. Give a call to your city building permit departing and just ask how to find out about the electrical codes for the city first and see if you can recover them, replace them or have an electrician do the work. Tell them you have a friend who is calling about buying a house that has aluminum wire outlets and don't give any information. Building codes may be listed on a town or county's web site or read up on it. Once you know what's allowed, you can decide what to do about it. remember, always be very careful with electricity.

- Q: Is it easy to bend aluminum coils and what factors affect their flexibility?

- <p>Aluminum coils are relatively easy to bend due to their malleability and flexibility. However, the ease of bending can vary depending on the alloy type, thickness, and temper of the aluminum. Thinner gauges and softer tempers are generally easier to bend. The process can be done manually or with machinery, and it's important to consider the coil's width and the radius of the bend to avoid cracking or other damage.</p>

- Q: How are aluminum coils used in the production of food processing equipment?

- Aluminum coils are commonly used in the production of food processing equipment due to their excellent thermal conductivity, corrosion resistance, and lightweight nature. These coils are often formed into various shapes and sizes to create components like heat exchangers, evaporators, and condensers that help regulate temperature during food processing. Additionally, aluminum coils can be easily cleaned and sanitized, making them ideal for use in the food industry where hygiene is crucial.

- Q: Can aluminum coils be used for electrical wiring?

- Indeed, electrical wiring can make use of aluminum coils. Aluminum, known for its exceptional electrical conductivity, has served as a reliable choice for electrical wiring in the past. Nevertheless, it is worth noting that aluminum wiring is not as commonly employed as copper wiring due to certain concerns. Specifically, aluminum exhibits a higher resistance compared to copper, potentially resulting in increased power losses and heat generation. Additionally, aluminum has a tendency to oxidize, posing potential fire hazards. In order to address these issues, special measures must be taken when utilizing aluminum wiring, such as employing larger gauge wires and utilizing connectors explicitly designed for aluminum. While copper wiring is generally preferred due to its lower resistance and superior conductivity, aluminum wiring can still be utilized effectively with proper precautions.

- Q: What are the different types of aluminum coils?

- There are several different types of aluminum coils available, each with its own unique properties and uses. Some common types include: 1. Plain Aluminum Coils: These coils are typically made from pure aluminum and are used in a variety of applications, including packaging, construction, and automotive industries. 2. Embossed Aluminum Coils: These coils have a textured or patterned surface, which adds aesthetic appeal and can enhance the grip or provide anti-slip properties. They are commonly used in architectural designs, signage, and decorative applications. 3. Color Coated Aluminum Coils: These coils have a protective coating applied to the surface, providing enhanced durability, weather resistance, and aesthetic customization. They are often used in building facades, roofing, and cladding systems. 4. Anodized Aluminum Coils: Anodization is an electrochemical process that forms a layer of oxide on the surface of the aluminum, making it more resistant to corrosion and wear. Anodized aluminum coils are commonly used in architectural applications, electronics, and automotive parts. 5. Pre-painted Aluminum Coils: These coils have a layer of paint applied to the surface, providing protection against weathering and adding color aesthetics. They are frequently used in the construction industry for roofing, siding, and insulation purposes. 6. Stucco Embossed Aluminum Coils: These coils have a raised pattern resembling stucco, which adds texture and enhances the strength of the aluminum. They are commonly used in refrigerators, air conditioners, and other appliances. 7. Clad Aluminum Coils: Clad aluminum coils consist of two or more layers of aluminum bonded together for enhanced strength, durability, or specific properties. They are used in various industries, such as aerospace, defense, and transportation. Overall, the choice of aluminum coil type depends on the specific application requirements, such as desired appearance, corrosion resistance, durability, and mechanical properties.

Send your message to us

Aluminum 5052 Coil Price of 8011 and Aluminum Coil Manufacturer in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords