Interior Decor Ceiling Aluminium Frame

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

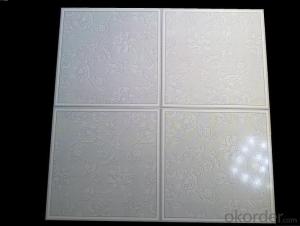

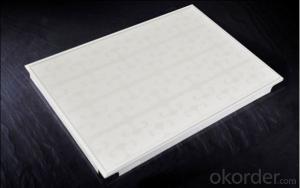

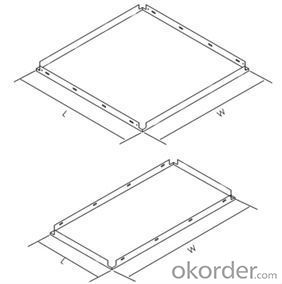

| Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

| Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

| 600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

| 800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

| 300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

| 600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

| Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

| 575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

| 585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

| 585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

| 595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

| 603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

| Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

| Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

| 75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

| 100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| 125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| 150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

| 200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

| Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

| C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

| G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

2) Specifications:

| Specification | Thickness | Height | Legend |

| 300×300mm | 0.4-1.0mm | 19mm(short edge) 25mm(High edge) |  |

| 300×450mm | |||

| 300×600mm | |||

| 300×1200mm | |||

| 400×400mm | 0.5-1.2mm | ||

| 500×500mm | |||

| 600×600mm | |||

| 600×1200mm | |||

| Base materials | Aluminum alloy, the grade of aluminum alloy can be selected according to the actual requirements; Besides, galvanized iron and stainless steel material is also available | ||

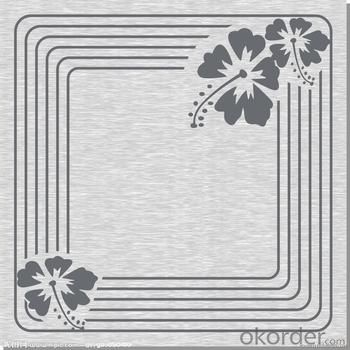

| Surface treatment | Powder coated(ordinary powder, Polyester powder), Paint coated, Film coated | ||

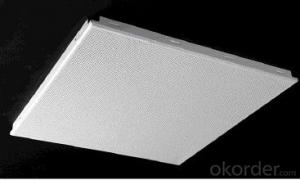

| Type of Surface | Plain plate or perforated plate is selected according to the actual requirements | ||

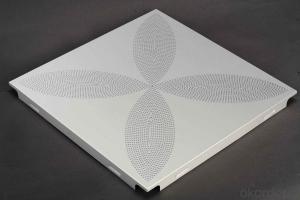

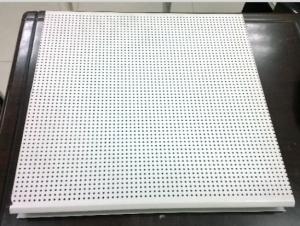

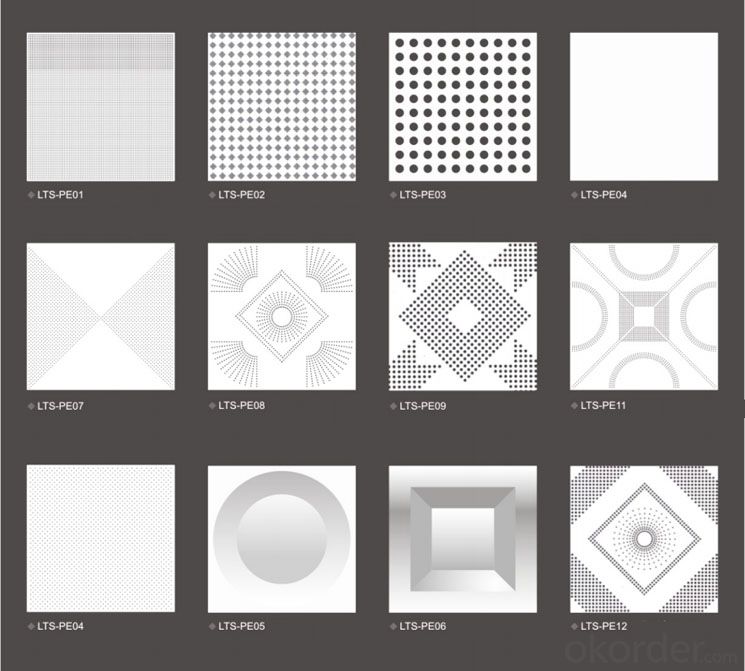

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

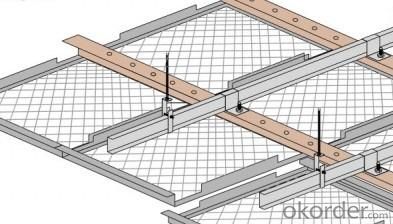

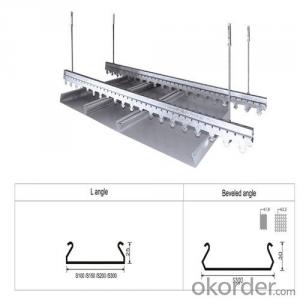

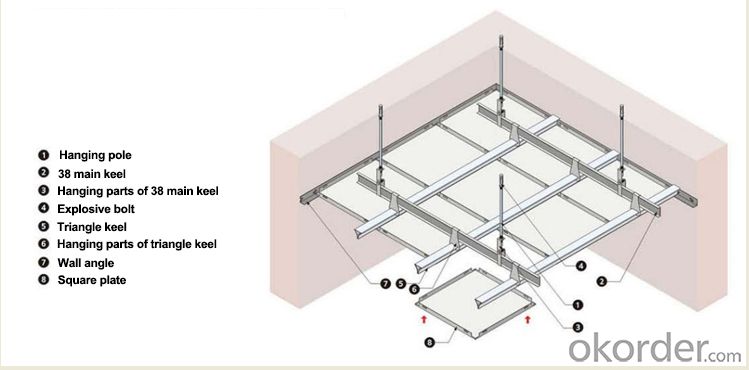

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

- Q: Aluminum slab ceiling and mineral wool board ceiling which is better and more expensive

- Such as offices, large public places. This kind of place is relatively important for the fire function. For this aspect more value. The use of different categories, you have to choose according to the specific purpose of use.

- Q: What is uv aluminum buckle board Uv stands for anything

- Friends, you may not be familiar with building materials. UV aluminum gusset plate, where the UV that the actual buckle plate shape, the whole meaning is to express: UV type of aluminum plate, which is also used in the building materials are more, in essence, or aluminum plate.

- Q: Magnet suction does not suck aluminum buckle plate?

- Do not smoke, it only sucks iron metal

- Q: Buy aluminum plate, need to pay attention to what

- Aluminum plate with a micro-punching board, some people recommend the use of the bathroom, that is able to moisture. I think the reason for the drop of water is: when the water will rise when the bath, by the ceiling block, will be in the aluminum plate under the surface of the condensate into a small water droplets, after bath to open the bathroom, cold air into the water droplets become more and more dew. With the use of micro-punching aluminum plate, the steam can be through the micro-punching into the top of the ceiling, condensed into water droplets, due to the surface tension of water, can not pass through the micro-punching, only slowly above the ceiling evaporation. But if we look at the bathroom as a whole, with the micro-punching of the aluminum plate is only a place to move the moisture, and can not solve the problem of moisture, but will make the top part of the ceiling more humid. Now the bathroom is generally by Yuba, exhaust fan row of tide, electrical fear of the tide, the use of micro-punching with the aluminum plate instead of the use of electrical appliances.

- Q: Is the aluminum slab ceiling applicable to the corridor?

- The general size of the corridor can not use a few pieces are complete aluminum plate, if there is not part of the whole piece, it is not beautiful. Not recommended.

- Q: What are the specifications of the aluminum ceiling?

- Aluminum ceiling commonly used specifications Width and width (mm): 600x600, 600x1200, 300x1200, 300 x 300, 400 x 400, 500 x 500, Thickness: 0.45 mm, 0.5 mm 0.55 mm 0.6 mm 0.65 mm 0.7 mm 0.75 mm 0.8 mm 0.85 mm

- Q: Aluminum buckle ceiling ceiling labor costs how much

- Aluminum plate also has a grade, generally not with the film of more than 30 yuan / square meter, with the end of the film should also be more than 60 yuan / square meter, the installation of 15 yuan / square meter, 0.6MM thickness. On the grade Fumo film even a good installation of more than 100 yuan / square meters above, 0.8MM thickness.

- Q: Home improvement aluminum plate thickness in the end is how much is considered good

- Home decoration aluminum plate is not necessarily thick like.

- Q: Ceiling pvc buckle surface how to deal with more fashionable?

- Smallpox from gypsum board, mineral wool board, PVC, aluminum buckle board development so far, has been a long time. Aluminum plate before the advent of the current surface of the ceiling are: film, roll, spray three, one of the best film.

- Q: The top of the kitchen did not line, like the largest reduction in space, at least how high Is the kitchen

- Two probabilities, one is the commercial kitchen. Commercial kitchen, then taking into account the new wind, exhaust, fire pipe will be arranged at the top of the kitchen.

Send your message to us

Interior Decor Ceiling Aluminium Frame

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords