Alloy Steel SCM435 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alloy Steel SCM435 Round Bars

Specification

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Equivalent grades

| GB | DIN | AISI | JIS |

| 35CrMo | 1.7220 | 4135 | SCM345 |

Chemical Composition (%)

| C | Si | Mn | Cr | Mo | Ni | Cu | P | S |

| 0.32-0.40 | 0.17-0.37 | 0.40-0.70 | 0.80-1.00 | 0.15-0.25 | ≤0.030 | ≤0.030 | ≤0.035 | ≤0.035 |

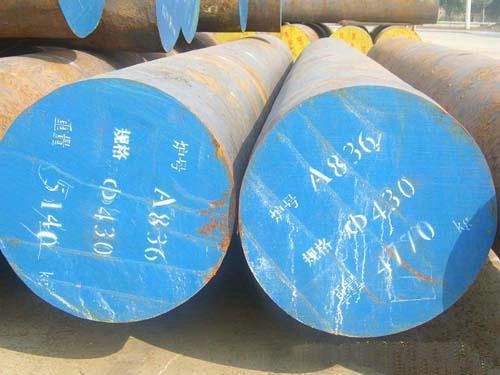

Products Show

Product Overviews

Description | Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, Mild steel shaft,ms bar | |

Material | ASTM | 1005, 1006, 1008, 1010, 1015, 1020, 1025, 1030, 1035, 1040, 1045, 1050, 1055, 1060, 1065, 1070, 1080, 1084, 1016, 1022 |

DIN | Ck10, Ck15, Ck22, Ck25, Ck30, Ck35, Ck40,Ck45, Ck50, 30Mn4, 40Mn4 | |

BS | 040A04, 095M15, 045M10, 080A40, 045M10, 080M50 | |

JIS | S09CK, S9CK, S10C, S15C, S20C, S25C, S30C, S35C, S40C, S45C, S50C, S55C, S58C, SB45, S30C, S40C, S45C, S53C | |

Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| Section shape | Round, square, hexagonal, flat, angle | |

| Surface | Black painted, galvanized | |

Specifications | Round bar | Diameter: 4mm~1200mm |

Angle bar | Size: 3mm*20mm*20mm~12mm*800mm*800mm | |

Square bar | Size: 4mm*4mm~100mm*100mm | |

Flat bar | Thickness: 2mm~100mm | |

Width: 10mm~500mm | ||

| Hexagonal | Size: 4mm~800mm | |

Length | 2m, 4m, 5.8m, 6m, 11.8m, 12m or as required. | |

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What are the scientific names of round bar and screw steel?

- Round steel: round steel refers to the cross section of round solid steel. Mainly used in manufacturing machine, stainless steel round bar, mechanical parts, seamless steel pipe blank

- Q: Can steel round bars be plated with other metals?

- Yes, steel round bars can be plated with other metals through a process called electroplating.

- Q: What are the different types of steel round bar alloys for improved machinability and strength?

- Improved machinability and strength can be achieved with several variations of steel round bar alloys. These alloys are designed specifically for industries where efficient machining and high tensile strength are essential. Here are some of the popular alloys used: 1. 12L14: This alloy incorporates lead, functioning as a lubricant during machining. This results in improved chip formation and reduced tool wear. Its exceptional machinability and good strength make it ideal for applications involving intricate machining processes. 2. 4140: Known as "chromoly" steel, this alloy contains chromium and molybdenum, which enhance its strength and hardenability. It is extensively used in applications that demand high tensile strength, such as automotive parts, shafts, and gears. 3. 8620: This low-alloy nickel-chromium-molybdenum steel offers a combination of high strength and good toughness. It can be easily machined and is commonly employed in case-hardening applications like gears, shafts, and fasteners. 4. 1018: Referred to as "cold-rolled" or "cold-finished" steel, 1018 is a low-carbon alloy with good machinability and weldability. It finds common usage in applications requiring precise and smooth finishes, such as bolts, screws, and hydraulic fittings. 5. 52100: This high carbon, chromium-bearing steel is primarily used for manufacturing bearings and other high-wear applications. It offers excellent hardness, wear resistance, and machinability, making it suitable for components necessitating strength and durability. These examples illustrate the range of steel round bar alloys available to enhance machinability and strength. The choice of alloy depends on specific application requirements, including desired strength, machinability, and durability. Consulting with a materials engineer or supplier can assist in identifying the most suitable alloy for a particular use case.

- Q: Can steel round bars be used for making staircases?

- Yes, steel round bars can be used for making staircases. They provide durability, strength, and a modern aesthetic appeal to the staircase design.

- Q: What are the advantages of using nickel-silicon alloy steel round bars?

- Nickel-silicon alloy steel round bars offer numerous benefits. Firstly, they possess outstanding strength at high temperatures and are resistant to oxidation and corrosion. Consequently, they are well-suited for applications in extreme environments, such as the aerospace and automotive industries. Secondly, these round bars exhibit superior mechanical properties, including high tensile and yield strength. As a result, they are ideal for use in structural components that require durability and strength, like construction and engineering projects. Additionally, nickel-silicon alloy steel round bars demonstrate excellent resistance to fatigue and wear. Therefore, they are perfect for applications involving repetitive stress or abrasive conditions. This ensures extended lifespan and reduced maintenance requirements for components made from this material. Furthermore, nickel-silicon alloy steel is renowned for its exceptional magnetic properties, making it suitable for electromagnetic applications such as transformers, motors, and generators. Lastly, nickel-silicon alloy steel round bars can be easily machined and fabricated, allowing for greater design flexibility and ease of manufacturing. Consequently, they are a cost-effective choice for various industries, as they lower production costs and lead times. In summary, the advantages of nickel-silicon alloy steel round bars include resistance to high temperatures, excellent mechanical properties, fatigue and wear resistance, superior magnetic properties, and ease of machining and fabrication.

- Q: How is the weight of a steel round bar calculated?

- The weight of a steel round bar is calculated using the formula: weight = volume × density. The volume of a round bar is determined by multiplying the cross-sectional area (πr^2) with the length of the bar. The density of steel is usually known, so by plugging in these values, we can calculate the weight of the steel round bar.

- Q: Can steel round bars be annealed?

- Steel round bars can indeed undergo annealing, a heat treatment process in which the steel is heated to a specific temperature and gradually cooled. This procedure serves to alleviate internal stresses, enhance ductility, and improve the steel's machinability. Annealing can be employed on various steel products, including round bars, to render them more pliable, easier to work with, and minimize the likelihood of cracking or failure in subsequent manufacturing procedures.

- Q: What are the environmental impacts of steel round bar production?

- The production of steel round bars has several environmental impacts. Firstly, the extraction of raw materials such as iron ore and coal required for steel production leads to habitat destruction, deforestation, and disruption of ecosystems. Mining activities also generate large amounts of waste, including tailings and waste rock, which can contaminate soil, water bodies, and air. The process of converting iron ore into steel involves high energy consumption, primarily from fossil fuels. The burning of these fuels releases greenhouse gases, such as carbon dioxide and nitrogen oxides, contributing to climate change and air pollution. Additionally, steel production releases particulate matter, sulfur dioxide, and other pollutants that can have detrimental effects on human health and ecosystems. Steel manufacturing also requires significant amounts of water for cooling, cleaning, and processing. This can lead to water scarcity and pollution if proper water management practices are not in place. Discharge of untreated or inadequately treated wastewater from steel production can contaminate nearby water sources, affecting aquatic life and potentially harming human populations who rely on these water bodies. Furthermore, the transportation of raw materials and finished steel products over long distances contributes to carbon emissions and air pollution. The energy-intensive nature of steel production and transportation further exacerbates the overall environmental impacts of the industry. To mitigate these environmental impacts, the steel industry has been implementing various measures. These include the use of more efficient technologies, such as recycling and minimization of waste, improving energy efficiency, and adopting cleaner production processes. Additionally, the industry has been focusing on reducing its carbon footprint by increasing the use of renewable energy sources and implementing carbon capture and storage technologies. Overall, while steel round bar production contributes to environmental degradation, there are ongoing efforts within the industry to minimize its negative impacts and transition towards more sustainable practices.

- Q: How do steel round bars perform in low-temperature environments?

- Low-temperature environments are typically suitable for steel round bars, as they tend to perform well in such conditions. The mechanical properties of steel, including strength and toughness, are usually maintained even at low temperatures. However, it is crucial to consider the grade of steel being used, as certain grades may exhibit reduced impact resistance or brittleness when subjected to extremely low temperatures. One common concern is the possibility of brittle fracture occurring in steel round bars under low-temperature circumstances. This can happen when the steel undergoes a transition from a ductile to a brittle state. Nevertheless, most standard steel grades employed in construction and industry are designed to resist brittle fracture even in low-temperature environments. Certain special alloy steels, such as low-temperature carbon steels, are specifically formulated to exhibit superior performance in extremely cold conditions. These steels contain additional elements, such as nickel or manganese, which enhance their low-temperature properties. They are frequently utilized in applications that require exceptional toughness and impact resistance, such as offshore structures or cryogenic storage tanks. In conclusion, steel round bars generally exhibit good performance in low-temperature environments while maintaining their mechanical properties. However, it is essential to carefully select the appropriate steel grade for the specific low-temperature application in order to ensure optimal performance and prevent potential issues like brittle fracture.

- Q: How are steel round bars tested for quality and compliance?

- Steel round bars are tested for quality and compliance through various assessment methods such as visual inspection, dimensional measurements, chemical composition analysis, and mechanical property testing. These tests ensure that the bars meet the required standards, strength, and durability for their intended applications.

Send your message to us

Alloy Steel SCM435 Round Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords