ALLOY HOT ROLLED ROUND BAR JIS/GB/DIN STANDAR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

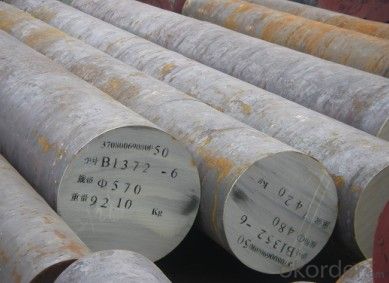

Specifications of Bearing Steel Round Bar

Grade | AISI 52100, ASTM E52100, DIN 1.3505,JIS SUJ2, GCr15 |

Dimensions | Diameter: 30-60mm Length: 2000-13000mm or as required |

Shape | Round Bar |

Type | Alloy Steel Bar |

Delivery Condition | Black Surface |

Material | Bearing Steel |

Technique | Hot Rolled |

Usage and Applications of Bearing Steel Round Bar

Bearing steels are used for ball and roller bearing applications and are comprised of low carbon steels and high carbon through harden able steel.

First the famous 1C-1.5Cr steel from which the majority of bearings are made. Its structure is apparently well-understood and the focus is on purity in order to avoid inclusions which initiate fatigue during rolling contact. Then there is the M50 steel and its variants, from which bearings which serve at slightly higher temperatures in aeroengines are manufactured, based on secondary-hardened martensite.

Tapered roller bearing are generally used to support combined load mainly consisting of radial load. Their cups are separable for easy assembling ,During mounting and using, radial clearance and axial clearance can be adjusted and preloaded mounting can be made.

Packaging & Delivery of Bearing Steel Round Bar

Packaging Detail: ASTM 52100 Steel in seaworthy packing or on customer request; Packed in bundles with standard export sea-worthy package or as customer require

Delivery Detail: 45 days after confirmed

Trade terms: FOB, CFR, CIF ou as customer's required

MOQ: 25 tons or at customer's demands. If the quantity is good, the price will be better.

Processing of Bearing Steel Round Bar

The processing of Bearing Steel Round Bar is hot rolled (strictly control sulphur, phosphorus and non-metallic inclusions content and distribution)

Chemical Composition of Bearing Steel Round Bar

C | Si | Mn | Cr | Ni | Cu |

Equal or less than | |||||

0.95-1.05 | 0.15-0.35 | 0.25-0.45 | Cr:1.40-1.65 | 0.30 | 0.25 |

All products' chemical composition and specification can be design according to customers' requirement.

Note of Bearing Steel Round Bar

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electros lag re-melting (ESR) steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

5. Certificate of quality is issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness. forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the certificate of quality.

- Q: Can steel round bars be used in the production of shafts?

- Yes, steel round bars can be used in the production of shafts. Steel round bars are commonly used in shaft manufacturing due to their high strength, durability, and ability to withstand heavy loads and torsional forces. They can be machined and shaped into the desired dimensions and specifications required for shafts in various industries such as automotive, aerospace, machinery, and construction.

- Q: What is the tolerance level for steel round bars?

- The tolerance level for steel round bars can vary depending on the specific industry standards and requirements, but commonly, it falls within a range of +/- a few millimeters or less.

- Q: What are the different types of steel round bar surface treatments used in the aerospace industry?

- In the aerospace industry, the different types of steel round bar surface treatments commonly used include various coatings such as nickel plating, chrome plating, zinc plating, and anodizing. These treatments are applied to enhance the corrosion resistance, improve the durability, and provide a visually appealing finish to the steel round bars used in aerospace applications.

- Q: Are steel round bars suitable for bridge construction applications?

- Yes, steel round bars are suitable for bridge construction applications. Steel is known for its strength, durability, and versatility, making it an ideal material for bridge construction. Steel round bars provide excellent structural support and can withstand heavy loads and harsh environmental conditions. Additionally, steel round bars can be easily fabricated and customized to meet specific bridge design requirements.

- Q: How do steel round bars compare to titanium round bars?

- Steel round bars and titanium round bars have distinct properties and are used for different purposes. Steel round bars are known for their high strength, durability, and affordability. They are commonly used in construction, manufacturing, and general engineering applications. On the other hand, titanium round bars are much lighter, have superior corrosion resistance, and exhibit high strength-to-weight ratio. This makes them suitable for aerospace, medical, and marine industries where weight reduction and resistance to harsh environments are crucial. Ultimately, the choice between steel and titanium round bars depends on the specific requirements and desired characteristics for the intended application.

- Q: What is the difference between a turned and a polished steel round bar?

- A turned steel round bar and a polished steel round bar both undergo separate processes that result in different surface finishes and properties. A turned steel round bar is typically created by using a lathe machine to remove material from the surface of a steel bar. This process involves rotating the bar against a cutting tool, which cuts away the outer layer and leaves behind a smooth and cylindrical surface. The turned bar may have visible machining marks due to the cutting process, although it is generally considered to have a more precise and uniform diameter compared to other types of steel bars. Turned bars are often used in applications where dimensional accuracy is crucial, such as in machinery or tooling. On the other hand, a polished steel round bar undergoes a different process that involves grinding or buffing the surface to achieve a smooth and reflective finish. Polishing removes any imperfections or roughness from the surface of the steel bar, resulting in a highly lustrous appearance. Polished bars are often used in decorative applications or where visual aesthetics are important, such as in architectural designs or high-end consumer products. In summary, the main difference between a turned and a polished steel round bar lies in their respective manufacturing processes and resulting surface finishes. A turned bar is machined to achieve precise dimensions, while a polished bar is subjected to a polishing process to obtain a smooth and reflective surface. The choice between the two depends on the specific requirements of the application, with turned bars being preferred for dimensional accuracy and polished bars for aesthetic appeal.

- Q: Can steel round bars be used for making automotive chassis?

- Yes, steel round bars can be used for making automotive chassis. Steel round bars offer excellent strength, durability, and load-bearing capabilities, making them suitable for withstanding the weight and stress of an automotive chassis. Additionally, steel's flexibility and malleability allow for customization and shaping to meet specific design requirements.

- Q: What are the advantages of using spring steel round bars?

- Some advantages of using spring steel round bars include their high tensile strength, excellent resilience, and durability. They are able to withstand heavy loads and provide reliable support in various applications. Additionally, spring steel round bars offer good flexibility and are resistant to bending or breaking, making them ideal for use in springs, tools, machinery, and automotive components.

- Q: Can steel round bars be machined easily?

- Yes, steel round bars can be machined easily due to their excellent machinability properties.

- Q: Can steel round bars be used in the electronics industry?

- Although steel round bars are not commonly used in the electronics industry due to their limited applications and low electrical conductivity, they can still find some utility in this field. Instead of being utilized in electronic components or circuitry, materials with high electrical conductivity like copper or aluminum are typically preferred. These materials allow for efficient transmission of electrical signals and minimize losses. Nonetheless, steel round bars can serve various purposes in the electronics industry. They can be employed for structural functions, providing support or reinforcement to electronic equipment or enclosures. Additionally, they can be utilized in the manufacturing of different mechanical components, connectors, or fixtures used in electronics assembly. Furthermore, steel round bars can be applied in the construction of equipment racks, shelves, or storage systems for electronic devices. In summary, although steel round bars are not directly involved in the electrical aspects of the electronics industry, they still play crucial roles in terms of structural support and mechanical components.

Send your message to us

ALLOY HOT ROLLED ROUND BAR JIS/GB/DIN STANDAR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords