High-Alumina Brick Raw Materials:86% Al2O3 Round Kiln Calcined Bauxite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

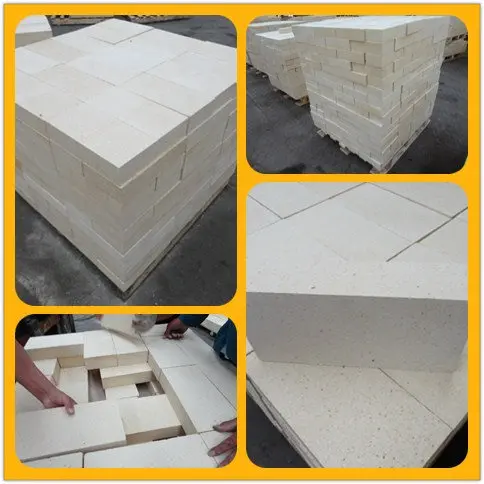

High alumina bricks

description

Specifications of high alumina bricks

1. AL2O3 : 45%-80%.

2. Can according to customers' requirements.

3. Used for steel ladle lining.

High alumina steel ladle fire brick,Steel ladle brick,Ladle brick

Application of high alumina bricks

High alumina brick is widely used for Widely used in blast furnaces, Hot Blast Stove, Steel ladle lining, Reheating furnace, Cement kiln,Tunnel kiln,boiler, coke oven, carbon furnace,glass kiln , Steel smelting furnace and various kiln lining and thermal technical equipment, etc.

Features of high alumina bricks

1) High-temperature endurable .

2) Good thermal shock resistance .

3) Good resistance to abrasion and corrosion.

4) Good thermal shock and thermal spalling resistance.

5) High mechanical strength.

6) Good volume stability at high temperature.

Physical and chemical index of high alumina bricks

Item | Specification | ||||||

LZ-85 | LZ-80 | LZ-75 | LZ-65 | LZ-55 | LZ-48 | ||

Al2O3 | 85 | 80 | 75 | 65 | 55 | 48 | |

Apparent density | 23 | 22 | 23 | 23 | 22 | 22 | |

Cold crushing strength | 65 | 55 | 50 | 45 | 40 | 35 | |

RUL | 1600 | 1530 | 1520 | 1500 | 1450 | 1420 | |

PLC | 1500.C*2h | 0.1~-0.4 | |||||

1450.C*2h | 0.1~-0.4 | ||||||

Standards of Type Brick:

| 230mmx114mmx65mm

Product Range: SK32,SK34,SK35,SK36,SK37,SK38

| ||||||

Specail Shape of High Alumina Brick

- Q: What are the materials of white firebricks?

- White refractory materials are generally divided into two types, namely, unshaped refractory materials and shaped refractory materials. Unshaped refractory materials, also called castables, is a mix of powdery particles of many aggregates and one or multiple adhesives. They must be stirred well with one or multiple liquids when in use, which has a strong liquidity. Unshaped refractory materials generally refers to firebricks. They have standard rules about their shapes and can also be processed temporarily as needed.

- Q: The fire prevention board line is made of what material?

- Crural line: wooden, in the market, there are sjoiner woodblock, peach wood and artificial engraving. The second classification is stone and the most used one is the marble graved or ceramics well-made one is taken as the first choise. Its price is a little bit expensive than the wooden one, but also a suitable choise. Condole supports: It has various category. The general furniture choose plaster and anti-firing plate and the other also have a choice of steel. You can make a suitable choice according to the need. If it is contracting project, it depends on your project specific plan and funds plan. In a word, beauty and harmony should be given priority since it is the source of design.

- Q: Is refractory material harmful to human body?

- Chromium oxide is poisonous in alkaline environment, and the gas produced by heating of asphalt, asphalt and refractory material is poisonous............ Go to the real estate company experts, I can think of these

- Q: What kind of material is good for cabinet fireproof board

- What kind of material is good for cabinet fireproof board What are the advantages and disadvantages of using it? How much is the price? A about how much does one piece cost?

- Q: How long does it take for refractory cement to solidify?

- 1. First you should be aware of the concepts of condensation and condesation time. Refractory cement belongs unshaped refractories, which when added water or liquid binding agent to mix, the agitation material will gradually lose thixotropy or plasticity and become in a state of solidification, thus is solidified. The time needed to finish the process is called solidification time. The whole process is divided into initial and final set. When beginning to lose plasticity called the initial setting, when called plasticity completely lost the final setting. 2. For refractory cement, the solidification time depends on the matching of the material and the parts and using methods. Under normal circumstances, in order to meet the requirements of time of construction, the initial set time should be no shorter than 40min, and the final set time should be no longer than 8H 3. There are also some exceptions. When refractory cement is used for spraying and injection operation together with other refractory castable, the set time is required as short as possible, sometimes flash set is required to prevent the occurrence of peeling or collapse of the spraying layer.

- Q: In entering fire door, which material does well?

- Hello: The basic material has steel, wood, or steel. The fireproof sandwich board, such as rock wool and perlite. The material of fire door, fire door has steel fire door and wooden fire door. There is no doubt that wooden fire door can't be used as entering door. In the steel fire door, two layers of steel plate in the clip is flame retardant material. In general, there is no lock. Of course, you can add locks in it, but it doesn't have pry proof function. I hope my answer can help you.

- Q: Does anyone know what is a lightweight refractory material?

- Heat preservation and insulation layer used only for Thermal Equipment has poor wear resistance, loose organization and high porosity(40%~85%) . The definition of light refractory material: low thermal conductivity, good performance in thermal insulation , weak mechanical strength, low volume density(generally below 13).

- Q: How many external wall thermal insulation fireproof material are there

- Class A exterior wall insulation: Rock wool, glass wool, silicate, aluminum silicate, calcium silicate, phenolic foam, foam glass

- Q: Who knows the texture of fire-proof wooden door material?

- The so-called fire doors are only posted a layer of fireproof material. Door selection still depends on the timber inside. The simplest way is to see the weight value, fireproof material layer, and they are generally paint-free doors. with fireproofing function..

Send your message to us

High-Alumina Brick Raw Materials:86% Al2O3 Round Kiln Calcined Bauxite

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords