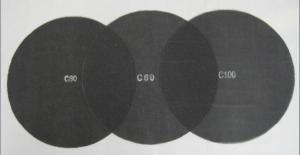

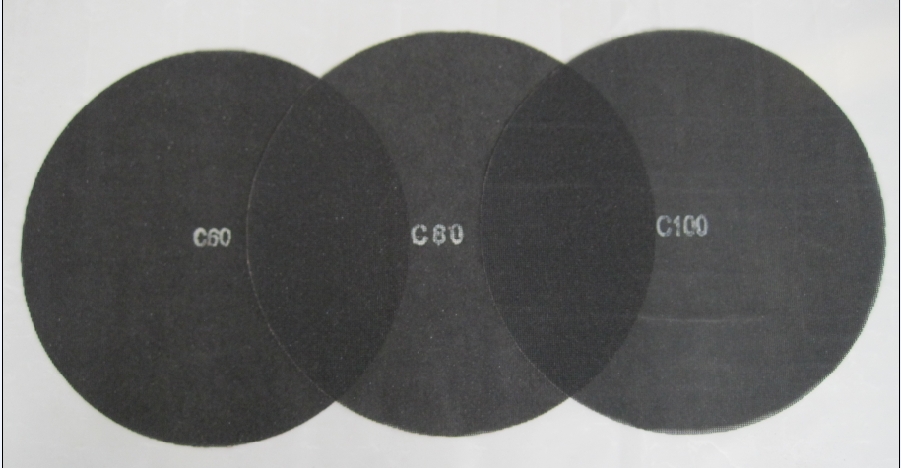

Abrasive screen—A400#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Abrasive sanding mesh screen is made of nylon fabric, coated with

abrasive materials; there are three kinds of shape: Sheets, Discs and

Rolls.

It is not only suitable for sanding plaster and wall surface, but also for

sanding rusty spots of metal materials and making grinding and

polishing treatment. It has good

properties of grinding, cutting and filings

removing. And it is the most ideal

abrasive tool for interior decoration.

- Q: Gypsum board wall with a square with the number of light steel keel

- Keel per square 10 yuan (including the ground, vertical, the main keel, screws, etc.), artificial 8 yuan or so. Sound insulation cotton plus 8 yuan per square. This is the price of the price

- Q: Silent barrier of high-speed railway is generally how much load

- 1, Overview With the rapid development of China's road network, sound barrier as a solution to the current traffic noise problem, has been more and more applications. However, from the current domestic built sound barrier effect, some are not very good, to the country and the people caused unnecessary waste. The main reason for this is that most of the sound barrier design is not scientific basis, blindness is relatively large. Where to set the sound barrier, and how to determine the length of the sound barrier (L), sound barrier height (H) and other parameters are determined by the feeling. Based on years of experience in sound barrier research and design practice, the author attempts to give the practical method and empirical formula of the above parameters in the design of sound barrier, which is designed and used by designers in the future sound barrier design.

- Q: What is the cost of geocells?

- The cost of geocells can vary depending on factors such as the size, material, and supplier. Generally, they range in price from a few dollars per square meter to upwards of $10 per square meter.

- Q: The amount of material is 70.66M2, the height of 5.2M plate thickness 120MM then its template to support the amount of high project is the amount of more than 3.6 meters per 1 meter per meter to calculate the template to support the high project I know, Asked how the template to support the high amount of how to get the project.

- The mold is stable, the structure is well-structured, the spacing of the bracket is arranged rationally, and the back ribs of the stent are set to meet the requirements of strength, stiffness, locality. Stability requirements. Internal mold with a special easy to unload the steel mold to ensure that the size of the construction of accurate, solid support.

- Q: Polypropylene geogrid

- Hello! ~ ~ ~ the so-called polypropylene is just a kind of material, the material has PP and polyethylene (HDPE) these two kinds

- Q: Are steel tube couplers compatible with scaffolding systems that require quick assembly and dismantling?

- Yes, steel tube couplers are compatible with scaffolding systems that require quick assembly and dismantling. Steel tube couplers are widely used in scaffolding systems due to their ease of use and versatility. They are designed to connect steel tubes together securely, allowing for quick and efficient assembly and dismantling of scaffolding structures. Steel tube couplers provide a strong and stable connection, ensuring the safety and stability of the scaffolding system. Additionally, they are adjustable and can be easily tightened or loosened as needed, making them suitable for various scaffolding configurations. Overall, steel tube couplers are an excellent choice for scaffolding systems that require quick assembly and dismantling.

- Q: Can steel tube couplers be used in scaffolding projects with limited access to tools or equipment?

- Yes, steel tube couplers can be used in scaffolding projects with limited access to tools or equipment. Steel tube couplers are designed to connect scaffolding tubes without the need for welding or specialized tools. They can be easily hand-tightened using only a hammer or wrench, making them suitable for projects with limited access to tools or equipment.

- Q: Can steel tube couplers be used in scaffolding projects with electrical installations?

- Yes, steel tube couplers can be used in scaffolding projects with electrical installations. Steel tube couplers are commonly used in scaffolding to connect tubes and provide structural stability. They are designed to securely hold the tubes together, ensuring the safety and stability of the scaffolding structure. When it comes to electrical installations, it is important to ensure that proper safety precautions are taken to prevent any electrical hazards. This includes using insulated tubing or conduit for electrical wiring and ensuring that the scaffolding structure is grounded properly. Steel tube couplers themselves do not interfere with electrical installations as long as the electrical components are properly insulated and placed within the designated conduits or tubes. However, it is recommended to consult with a qualified electrician or engineer to ensure that all electrical requirements and safety standards are met. They will be able to assess the specific project requirements and provide guidance on the suitable use of steel tube couplers in conjunction with electrical installations.

- Q: How to do the effect of water

- Water effect, is a rustic architectural style, the current application is also very common in the country. From Japan's Ando master.

- Q: How do steel props help in preventing structural collapse during construction?

- Steel props help in preventing structural collapse during construction by providing temporary support to the structure. They are adjustable and can be extended to the required height, providing stability and load-bearing capacity. Steel props distribute the weight of the structure evenly, reducing stress on the walls and beams. This prevents structural deformation and collapse, ensuring the safety of workers and the integrity of the construction site.

Send your message to us

Abrasive screen—A400#

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords