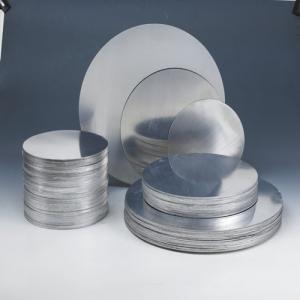

Roll of Aluminum Coil - AA 1070 Diameter 500mm Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum circles /sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: How are aluminum coils used in the production of automotive radiators?

- Aluminum coils are used in the production of automotive radiators as they provide excellent heat transfer properties. These coils are typically made from aluminum alloy, which is lightweight, corrosion-resistant, and has high thermal conductivity. The coils are formed into a specific shape and then attached to the radiator's core. As coolant flows through the coils, heat from the engine is transferred to the aluminum, which efficiently dissipates it. This helps in cooling the engine and maintaining its optimal operating temperature. Overall, aluminum coils play a crucial role in enhancing the efficiency and performance of automotive radiators.

- Q: Are aluminum coils suitable for chemical processing applications?

- Yes, aluminum coils are suitable for chemical processing applications. Aluminum is known for its excellent corrosion resistance and high thermal conductivity, making it an ideal choice for various chemical processes. It can withstand different chemicals and acids, and its lightweight nature allows for easy handling and installation. Additionally, aluminum coils provide good heat transfer and can be easily formed into various shapes, making them versatile for different chemical processing requirements.

- Q: What influence do aluminum coils have on the welding process?

- <p>Aluminum coils can significantly affect welding work due to their unique properties. Aluminum has a high thermal conductivity, which requires more heat input to achieve the necessary temperature for welding. It also has a high oxide layer that can interfere with the welding process, leading to porosity and poor joint strength if not properly managed. Additionally, aluminum's low melting point can cause challenges in maintaining the correct temperature during welding. Specialized techniques, such as TIG (Tungsten Inert Gas) welding, and the use of appropriate filler materials are often necessary to ensure a successful weld. Proper cleaning and preparation of the aluminum surface are also crucial to prevent contamination and ensure a strong, defect-free weld.</p>

- Q: the ingredient on the back says aluminum?also ..what is sodium benzoate?Is all this stuff that terrible for you? Or does it mean something else?

- The aluminum is in the baking powder. Very common but you can buy it without it, it is much healthier for you. Aluminum is correlated to Alzheimer's and ADD. Baked goods taste much better without the aluminum too. Benzoate of soda, a preservative that can alter your DNA. Not too good for you, no matter what the FDA may say about it. All told, if you are concerned for your health, keep to organic as much as possible and made from scratch too. Way too much junk is put in our food and health products.

- Q: Can aluminum coils be painted for custom designs?

- It is indeed possible to paint aluminum coils to achieve personalized designs. The act of painting the coils opens up a world of limitless options for customization and aesthetic appeal. Various colors, patterns, and designs can be applied to the coils, catering to individual tastes and needs. To complete the painting process, the surface must first be cleaned, followed by the application of a primer and the desired paint or coating. Through this method, one can create distinctive and captivating custom designs suitable for a wide array of purposes, including architectural elements, signage, automotive components, and more. Moreover, the paint not only safeguards the aluminum from corrosion but also enhances its durability.

- Q: How do aluminum coils contribute to sustainable building practices?

- Several ways exist in which aluminum coils contribute to sustainable building practices. To begin with, aluminum, being a highly recyclable material, has a minimal impact on the environment in terms of production and usage of aluminum coils. The process of recycling aluminum requires significantly less energy compared to the production of new aluminum, thereby reducing greenhouse gas emissions and conserving natural resources. Furthermore, aluminum coils possess the qualities of being lightweight and durable, making them an excellent choice for sustainable building practices. The lightweight nature of aluminum reduces the burden on the building structure, resulting in lower transportation costs and energy consumption during construction. Moreover, the durability of aluminum coils ensures a long lifespan, reducing the need for frequent replacements and the generation of associated waste. Additionally, aluminum's resistance to corrosion and minimal maintenance requirements contribute to the longevity of buildings, thereby reducing the need for repairs and replacements over time. This not only saves resources but also diminishes the overall environmental impact of the building. Moreover, aluminum coils exhibit excellent thermal conductivity, which can enhance energy efficiency in buildings. When incorporated into insulation systems or HVAC systems, aluminum coils assist in temperature regulation and minimize energy consumption. Consequently, this can lead to reduced energy bills and a smaller carbon footprint for the building. Lastly, aluminum coils find utility in various applications, including roofing, cladding, and ventilation systems. Their versatility allows for innovative and creative design solutions, supporting sustainable building practices by integrating energy-efficient features and promoting natural ventilation. In conclusion, aluminum coils contribute to sustainable building practices through their recyclability, lightweight and durable nature, resistance to corrosion, thermal conductivity, and versatility. By opting for aluminum coils in construction, we can reduce the environmental impact of buildings, conserve resources, and promote energy efficiency, ultimately fostering a more sustainable built environment.

- Q: Automotive aluminum coil, using GB H22, what brand, what are the main ingredients?

- In the corresponding foreign brands for AlMg3, 5754 different heat treatment is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry

- Q: What are the typical production volumes for aluminum coil manufacturers?

- The typical production volumes for aluminum coil manufacturers vary depending on the size and capabilities of the specific manufacturer. However, it is common for aluminum coil manufacturers to produce thousands to tens of thousands of tons of aluminum coils annually, catering to the demands of diverse industries such as construction, automotive, and packaging.

- Q: Can aluminum coils be used in automotive heat shields?

- Indeed, automotive heat shields can utilize aluminum coils. Thanks to its exceptional resistance to heat and lightweight characteristics, aluminum is extensively employed in heat shield production. By shaping and forming aluminum coils according to the desired design, automotive applications can benefit from straightforward installation and customization. Moreover, the high thermal conductivity of aluminum aids in efficiently dissipating heat, rendering it an optimal option for vehicle heat shields.

- Q: What is the typical modulus of elasticity for aluminum coils?

- The typical modulus of elasticity for aluminum coils is around 70 GPa (gigapascals).

Send your message to us

Roll of Aluminum Coil - AA 1070 Diameter 500mm Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords