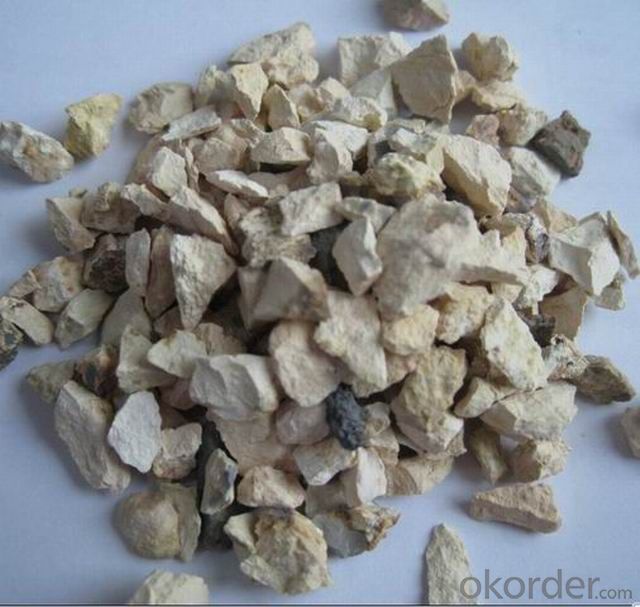

88% Calcined Bauxite - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Mingyue Bauxite and Calcined Bauxite:

Mingyue Bauxite, ie. bauxite ore, whose main content is Aluminium oxide with, who is department of hydrated

alumina containing impurities in appearance of earthy mineral;

Mingyue Calcined Bauxite is burnt bauxite, who is used for producing the existing uneven materin in nature --

alumina and aluminium. The purpose of calcining bauxite is to remove crystal water and improve the content of alumina.

Mingyue Bauxite Secification:

Al2O3 | Fe2O3 | TiO2 | K2O+Na2O | CaO+MgO | Bulk density |

≥65 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.6 |

≥75 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.7 |

≥80 | ≤2.5 | ≤4.0 | ≤0.3 | ≤0.5 | ≥2.8 |

≥85 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.0 |

≥86 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.1 |

≥87 | ≤2 | ≤4.0 | ≤0.3 | ≤0.5 | ≥3.2 |

≥88 | ≤1.8 | ≤4.0 | ≤0.25 | ≤0.5 | ≥3.25 |

Mingyue Refractory Bauxite Level:

Level | Chemical Composition (%) | Refractoriness (℃) | Bulk Density (g/cm3) | ||

Al2O3 | CaO | Fe2O3 | |||

superfine | >85 | <0.6 | <1.4.0 | >1790 | >3.6 |

first grade | >80 | <0.6 | <3.0 | >1790 | >3.0 |

second grade+1 | 70~80 | <0.8 | <3.0 | >1790 | >2.8 |

sencond grade | 60~70 | <0.8 | <3.0 | >1770 | >2.65 |

third grade | 50~60 | <0.8 | <2.5 | >1770 | >2.55 |

Product Uses

Mingyue Bauxite and Calcined Bauxite:

1. Aluminum industry;

2. Precision casting;

3. Refractory industry;

4. Silica acid aluminum firefibre;

5. Mixed with magnesium oxide, it can be an nice bonding agent, especially for pouring entire steel teeming ladle lining;

6. Manufacture bauxite cement, grinding abrasives;

7. Ceramic industry, and chemical industry for making aluminium compounds.

- Q: What is the common inorganic fireproof and thermal inuslation matertial?

- Ceramic foam insulation board is made from clay tailings, ceramic broken flake and river silt, which is the closed ceramics material with high porosity roasted in high temperature by advanced production technology and foam technology. Products have fire retardant, small deformation coefficient, aging resistance, stable performance, good environmental protection, good compatibility between wall base and plastering layer, good safety and soundness and a lifetime as long as the building itself.

- Q: what's the standard of fireproofing material?

- Class A1 is divided according to the combustion performance of GB8624-2006 building materials and products. Specific technical index requirements are: 1, the temperature rise ≤30 degrees;mass loss rate ≤50%; combustion duration time is 0; 2, main components, overall products, gross calorific value of external secondary components ≤2.0MJ/kg; any inner secondary component ≤1.4MJ/kg; (there are difference between homogeneous and non-homogeneous). Z802 building materials noninflammability testing furnace has to be used for testing technical indicators mentioned in test 1, using Z805 building materials combustion heat value to test technical indicators mentioned in test device 2.

- Q: I wanna ask you, which level is b1 fireproof and thermal inuslation matertial ??

- I soppose you mean rubber and plastic! Only rubber and plastic has b1b2 level. Level b1 is the fireproofing level b1, because the rubber and plastic does not belong to the fireproofing material. It only has fire?retardant. The wholesale of all kinds of thermal insulation material and construction need to look at the name, hope you adopt.

- Q: What are the specifications of fire resistant bag?

- Mesh number, namely hole number, refers to the hold number in each square inch. 5o mesh refers to 50 holes in each square inch and 500 mesh 500 holes. The larger the mesh number is, the more the holes are. The larger the mesh number is, the smaller the hole aperture is. Generally speaking, mesh number× aperture (microns) = 15000. For example, the aperture of a sieve of 400 mesh is about 38 microns; the aperture of a sieve of 500 mesh is about 30 microns.

- Q: What antioxidant will be used in refractories?

- Antioxidants (Antioxidants) is the material to prevent bad influence of oxygen. It is a kind of material that can help to capture and neutralize free radicals, the category of material to remove free radicals damage to human body. Some of the body's antioxidant is self-synthesis, others is also from the food supply. Strong antioxidant such as ASTA (short for astaxanthin), etc., generally human cannot synthesize and it must be intaked from food. (1)antioxidants in the food can protect food from oxidative damage and deterioration. (2) it has the antioxidant effect in the human body's digestive tract and prevent oxidative damage in the digestive tract. (3) after being absorped, it can play a role in other body tissues and organs. (4)It is derived from certain foods that have antioxidant effect of extract and can be used as a treatment drug. Antioxidant mechanism includs chelated metal ion, scavenging free radicals, quenching singlet oxygen and removal of oxygen and inhibit oxidase activity, etc

- Q: What are Grade-A waterproof inorganic thermal insulation materials?

- 1. Foam ceramic insulation board Foam ceramic insulation board is made of inorganic ceramic material by high temperature baking and is called ceramic insulation plate for short. 2. Composite cement foaming insulation board With cement, fly-ash and micro-silica, composite cement foaming insulation board is a kind of hole-closed lightweight hydrophobic insulation board made by foaming, maintenance,cuttign and processing. 3. Aerated concrete panel Using lightweight material, silicious material and foaming agent and so on, aerated concrete panel is a lightweight concrete panel made by high pressure steaming. 4. Rock wool board With natural igneous rock as material and thermosetting resin as binder, rock wool board is a panel made by melting in high temperature through centrifugation. I hope it can help you.

- Q: What's the material of fireproof and wear-resisting floor?

- 1. It is the kind of special concrete floor, and its production process is the same with that of the common concrete floor, but it uses different material which needs to be the pebbles and sand after processing with marbles and dolomite. 2. Fireproof floor is a kind of decorative material which is laid on the ground of the factory or large areas of floors. It does not support combustion or it is composed of flame retardant materials. Fireproof floor has two categories. One is composed of aggregate wear-resistant material which is solid particulate matter. Its construction method is to evenly spread aggregate wear-resistant particles on the surface layer of the concrete when the floor is just pouring concrete and solidified, and then a firm flame retardant layer will be formed on the surface layer. This is the the so-called carborundum wear-resisting floor. But this kind of material has many limitations and can only be used on the surface of the just poured concrete. In addition, it is easy to fade in color and not beautiful in appearance. So this is not fireproof floor in the strict sense. Here we focus on a new liquid coating fire protection floor, which is environment friendly, widely used and beautiful in appearance. 3. Wear-resistant floor has the characteristics of pressure resistance, strong wear resistance,oil resistance, and anti-infiltration. It is also dust-free and easy to clean. After entering the initial setting of concrete, construction can be started immediately. Construction period is usually longer, but better using effect will arise.

- Q: What's the fire resistance test method of doors and roller shutters?

- Fire resistance test method of doors and roller shutters: This standard specifies the fire resistance test method for roller shutter doors under standard fire conditions. The method is used to test the fire resistance of the ventilating duct when bearing the external fire (A duct) and internal fire (B duct). Fire resistance test of vertical ducts may be conducted referring to this standard. 1.Test specimen1.1 The test specimen is obtained by cutting from any part of the qualified metal tube unless otherwise relevant standard or mutual agreement specifies the cutting position of the metal tube. 1.2 Length of the specimen: L≈2.5D+50mm (D: outer diameter of the metal tube). The cut surface of the specimen must be perpendicular to the axis of the metal , and the seamed edge of the cut should be round off. Test method GB243-82 of metal tube necking 2. Test procedures 2.1 In the test, punch or press the metal tube into the tapered conical seat (see Figure) with a hammer or press machine, and make it uniformly diminished to the regulated shrinkage X which is calculated according to the following formula: Test method GB243-822 for metallic pipe necking: The inner wall of the seat cover used in the test should be polished, and has certain hardness and is coated with lubricating oil. Its conicity is 1:10, 1:5 or others in accordance with relevant standard provisions. If there is no provision, then adopt the conicity of 1:10. This standard is not suitable for: a) The pipeline whose fire resistance depends on the fire resistance of the ceiling; b) The pipeline with access door, unless otherwise the access door is included into the pipeline and tested together; c) The pipeline with two or three sides; d) Fume exhaust pipes;

- Q: Who knows the fire endurance of rock wool color plate?

- Colored steel rock wool board is used for areas with high fireproofing requirements. Colored steel rock wool board belongs to class A according to "Fireproof? Specification of Building Interior Decoration?Design" whose lifetime can reach more than 15 years, operating temperature can up to about 700 ℃, maximum fireproofing time is 6 hours. And rock wool colored plate is environmentally friendly materials, which is is the preferred material in the construction industry .

Send your message to us

88% Calcined Bauxite - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords