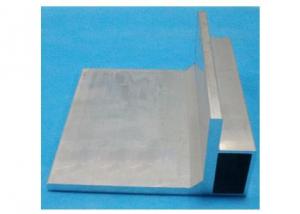

80/20 Anodized Alu Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the durability characteristics of aluminum profiles?

- Aluminum profiles are known for their exceptional durability characteristics. Due to the inherent properties of aluminum, such as its corrosion resistance, lightweight nature, and high strength-to-weight ratio, aluminum profiles are highly durable and long-lasting. One of the key durability characteristics of aluminum profiles is their resistance to corrosion. Aluminum naturally forms a thin oxide layer on its surface, which acts as a protective barrier against rust and other forms of corrosion. This makes aluminum profiles suitable for outdoor applications where they are exposed to harsh environmental conditions, such as rain, snow, and UV radiation. Additionally, aluminum profiles are able to withstand extreme temperatures without compromising their structural integrity. They have a high melting point and can resist thermal expansion and contraction, making them ideal for use in environments with fluctuating temperatures. Another important aspect of the durability of aluminum profiles is their strength. Despite being lightweight, aluminum is incredibly strong and can withstand heavy loads and impacts. This strength-to-weight ratio makes aluminum profiles a popular choice in various industries, including construction, automotive, and aerospace. Furthermore, aluminum profiles are highly resistant to wear and tear. They have excellent resistance to abrasion and can maintain their structural integrity even after prolonged use. This makes them suitable for applications that require long-term durability, such as window frames, door frames, and structural components. In summary, aluminum profiles possess remarkable durability characteristics due to their corrosion resistance, lightweight nature, high strength-to-weight ratio, thermal stability, and resistance to wear and tear. These qualities make them a reliable choice for a wide range of applications, ensuring their longevity and performance over time.

- Q: This question asks for a list of various types of coatings applied to aluminum profiles to prevent corrosion.

- <p>Aluminum profiles are protected from corrosion through several types of coatings. These include: Anodizing, which forms a protective oxide layer; Powder Coating, a durable and weather-resistant finish; Electrophoretic Deposition (E-coat), offering a smooth, corrosion-resistant surface; Fluoropolymer coatings, known for their exceptional chemical resistance and UV stability; and Thermal Spray Coatings, which provide a hard, wear-resistant surface. Each method serves to enhance the aluminum's resistance to environmental factors and extend its lifespan.</p>

- Q: This question asks for methods to prevent aluminum profiles from rusting during the storage and transportation phases.

- <p>To prevent rusting of aluminum profiles during storage and transportation, follow these steps: 1. Keep the profiles dry and clean, avoiding contact with moisture and corrosive substances. 2. Store them in a cool, dry place, away from direct sunlight and heat sources. 3. Use protective packaging, such as plastic wrapping or anti-corrosion paper, to shield the profiles from moisture and contaminants. 4. Ensure proper ventilation in storage areas to prevent condensation. 5. Avoid stacking profiles directly on the ground; use pallets or racks to elevate them and allow air circulation. 6. Regularly inspect the profiles for signs of corrosion and address any issues promptly. By implementing these measures, you can significantly reduce the risk of rusting during storage and transportation.</p>

- Q: Can aluminum profiles be used for electrical busbars?

- Indeed, aluminum profiles are capable of serving as electrical busbars. The utilization of aluminum in busbars is widespread as a consequence of its exceptional electrical conductivity, affordability, and lightweight properties. Aluminum profiles present a dependable and effective means for electrical distribution across a range of scenarios, encompassing power distribution systems, switchboards, and control panels. They boast commendable thermal conductivity, aiding in the dissipation of heat produced during periods of intense current flow. Nevertheless, when opting for aluminum profiles for busbar applications, it is crucial to take into account factors such as current carrying capacity, mechanical strength, and electrical insulation requirements.

- Q: This question asks about the various uses of aluminum profiles in the construction of buildings.

- <p>Aluminum profiles have a wide range of applications in building construction due to their strength, durability, and lightweight properties. They are used in window and door frames, curtain walls, and structural glazing systems for their high strength-to-weight ratio and resistance to corrosion. Additionally, aluminum profiles are utilized in the construction of balconies, handrails, and stairways for their ability to withstand harsh weather conditions. They are also employed in the fabrication of modular building systems and prefabricated components, offering ease of assembly and design flexibility. Furthermore, aluminum profiles are used in the construction of solar panel mounting systems and facades due to their thermal conductivity and ability to support heavy loads.</p>

- Q: This question asks for methods to ensure that the installation of aluminum profiles is both cost-effective and efficient.

- <p>To ensure the installation of aluminum profiles is cost-effective and efficient, follow these steps: 1) Plan carefully: Use accurate measurements and detailed plans to minimize waste and rework. 2) Use quality materials: Invest in high-quality aluminum profiles to reduce maintenance and replacement costs. 3) Employ skilled labor: Well-trained installers can complete the job faster and with fewer errors. 4) Optimize the installation process: Streamline the process to reduce time and labor costs. 5) Regular maintenance: Proper care and maintenance can extend the life of aluminum profiles, saving on replacement costs. 6) Compare suppliers: Shop around for the best prices and quality to minimize costs. 7) Use modular designs: Modular systems can be more efficient to install and easier to modify in the future.</p>

- Q: What are the different sealing options for aluminum profiles?

- There are several sealing options available for aluminum profiles, including anodizing, powder coating, liquid paint coating, and mechanical sealing. Anodizing is a popular choice, providing a durable and corrosion-resistant finish by creating a protective oxide layer on the surface of the aluminum. Powder coating involves applying a dry powder to the profile, which is then cured under heat to form a hard, smooth coating. Liquid paint coating can also be used, offering various colors and finishes, but may require more maintenance. Mechanical sealing involves using gaskets, tapes, or other sealing materials to create a tight seal between aluminum profiles. The choice of sealing option depends on the specific requirements of the application, such as desired aesthetics, durability, and environmental factors.

- Q: Where is the exact location? TwentyBecause I was doing aluminum sales, want to go to the market!Where is the specific market aluminum sales, as long as there is, I have to go around! Say where it is! For example, what area, what road, how many?! Since I went to Chengdu for the first time, please tell me more about it. Thank you!

- Two days ago in the city to find the north gate, Xinshengda profile market have taken a little more, Sammy, the gold house electrical city only one sell Aluminum Alloy, Wanguan electrical didn't go to see, tailor steel city to ask a security guard said little or no 512, no Aluminum Alloy sold, only 512 of the next street there is a Aluminum Alloy sell (416 opposite the hospital). Today I went to Qingbaijiang Fengxiang profile market. Where is the place where the aluminum alloy merchants gathered, the profiles, accessories, processing?...... Goods are available in all varieties。 But the aluminum doors and windows only home balcony with the majority, profile industry, such as steel rack chassis radiator with basically No. This market sells stainless steel materials, businesses are also more. Bus route Liang Jia lane to Qingbaijiang on the car, told the driver to Fengxiang market under the line, and 6 yuan fare, cheaper! Drive away the State Road 108 to Mi Mou Town, Fengxiang market in 108 State Road next great, far away saw. This is the latest information, 2013-9-12

- Q: How do you clean and maintain aluminum profiles?

- To clean and maintain aluminum profiles, you can follow these simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum profiles using a soft brush or cloth. 2. Prepare a cleaning solution by mixing mild dish soap or a non-abrasive cleaner with warm water. Avoid using harsh chemicals or abrasive cleaners as they can damage the aluminum finish. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum profiles. Be sure to clean all the corners and crevices thoroughly. 4. Rinse the profiles with clean water to remove any soap residue. You can use a hose or a bucket of water for this step. 5. Dry the aluminum profiles completely using a soft, lint-free cloth. This will prevent water spots or streaks from forming. 6. For regular maintenance, you can use a specialized aluminum cleaner or polish to restore the shine and protect the surface. Follow the instructions on the product for best results. 7. It is important to avoid using abrasive scrubbers, steel wool, or harsh chemicals as they can scratch or damage the aluminum finish. Also, never use acidic cleaners or vinegar on aluminum as they can cause corrosion. 8. If you notice any scratches or minor damages on the aluminum profiles, you can use a touch-up paint specifically designed for aluminum to repair them. Follow the manufacturer's instructions for application. Remember, regular cleaning and maintenance will help preserve the appearance and longevity of your aluminum profiles.

- Q: What are the specific requirements or considerations when using aluminum profiles in the construction or design of swimming pools and spas?

- <p>Yes, there are special requirements for using aluminum profiles in swimming pools and spas. These include corrosion resistance to withstand chlorinated water, which is common in pools and spas. Profiles must be made of marine-grade aluminum to prevent rust and ensure longevity. They should also be able to withstand high humidity and temperature fluctuations. Additionally, profiles need to be non-slip and easy to clean to maintain safety and hygiene. The design should also consider structural integrity to support the weight of the pool or spa structure and any associated equipment.</p>

Send your message to us

80/20 Anodized Alu Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords