8-650mm CK45 Steel Bar / 1045 Round Steel / S45C Steel Rod

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The details of our Steel

1. Produce Standard: as the GB, AISI, ASTM, SAE, EN, BS, DIN, JIS Industry Standard

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment:

Normalized / Annealed / Quenched+Tempered

4. Quality assurance:

All order we can received Third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product information

Chemical Composition(%) of S45C steel rod | C | Si | Mn | S | P | Cr |

0.43-0.50 | 0.17-0.37 | 0.60-0.90 | ≤0.04 | ≤0.04 | ≥0.30 | |

Specification of S45C steel rod | Diameter(mm) | Length(mm) | ||||

8-650 | 500-5800 | |||||

Material of S45C steel rod | A36,SS400,SPCC,SPHC, Q195, Q235,Q345 | |||||

Application of S45C steel rod | (1)Automotive suspension springs (2) Rotary tools and Blades | |||||

Payment Term of S45C steel rod | L/C or T/T, 30% in advance, 70% before the shipment | |||||

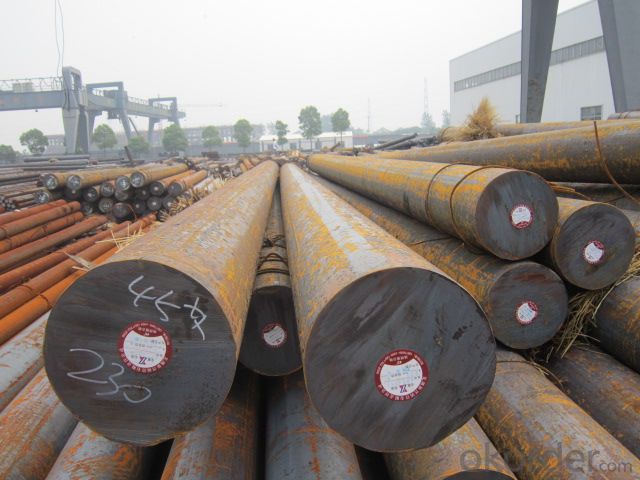

Product show

Workshop show

- Q: Can special steel be used in the construction industry?

- Yes, special steel can be used in the construction industry. Special steel, such as stainless steel or high-strength steel, offers various advantages including durability, corrosion resistance, and high strength-to-weight ratio. These qualities make it suitable for applications in building structures, bridges, reinforcement bars, and other construction components where strength and resistance to external elements are essential.

- Q: What are the main applications of special steel in the power distribution industry?

- Special steel is widely used in the power distribution industry for various applications. One of the main applications is in the construction of transmission towers and electrical pylons. Special steel is preferred for these structures due to its high strength, durability, and resistance to corrosion. It ensures the safe and reliable transmission of electricity over long distances. Special steel is also used in the manufacturing of electrical transformers and generators. The steel's magnetic properties make it suitable for creating efficient and reliable power generation and distribution equipment. Additionally, special steel is used in the production of electrical connectors and conductors, which are essential for ensuring the efficient flow of electricity through power distribution systems. Overall, the main applications of special steel in the power distribution industry include transmission towers, electrical pylons, transformers, generators, and electrical connectors. These applications play a crucial role in maintaining a robust and reliable power grid, ensuring uninterrupted electricity supply to consumers.

- Q: What are the factors affecting the cost of special steel?

- There are several factors that can affect the cost of special steel. Firstly, the cost of raw materials used in the production of special steel, such as iron ore and alloys, can have a significant impact on its overall price. Additionally, the level of demand for special steel, both domestically and globally, can influence its cost. Factors such as market competition, economic conditions, and government policies can also play a role in determining the price of special steel. Lastly, the complexity of the manufacturing process, including the level of skill required and the use of advanced technologies, can contribute to the higher cost of special steel compared to regular steel.

- Q: What are the different methods of controlling the grain size in special steel?

- To achieve desired mechanical properties and performance, there are multiple approaches available for controlling the grain size in special steel. The following are some of the techniques that can be employed: 1. Alloying: The grain size in steel can be controlled by carefully selecting and managing the composition of alloying elements. Elements like niobium, vanadium, and titanium have proven effective in refining the grain size. 2. Heat treatment: The grain size can be regulated through the process of heat treatment. Techniques such as annealing, normalizing, and quenching can be utilized to manipulate the grain size. For example, slow cooling during annealing encourages the growth of larger grains, while rapid cooling during quenching leads to smaller grain sizes. 3. Deformation processing: Mechanical deformation methods like rolling, forging, or extrusion can aid in refining the grain structure. These processes induce strain and facilitate the formation of smaller and more uniform grains. 4. Grain growth inhibitors: The addition of specific elements like aluminum or zirconium to the steel can act as inhibitors for grain growth. These elements create fine particles that impede the growth of grains during heat treatment, resulting in a smaller grain size. 5. Control of transformation temperature: Manipulating the transformation temperature during heat treatment allows for control over the grain size. Lowering the austenitizing temperature, for example, can yield a finer grain structure in the final product. 6. Rapid solidification: Employing techniques such as spray forming or rapid quenching can lead to an ultrafine-grained microstructure. The rapid cooling prevents grain growth, resulting in a fine and homogeneous grain structure. 7. Severe plastic deformation (SPD) techniques: Techniques like equal channel angular pressing (ECAP) or high-pressure torsion (HPT) impose significant strain on the material, leading to a refined grain structure. These methods are commonly used for producing ultrafine-grained or nanostructured steels. It is essential to consider the desired properties, alloy composition, and intended application of the final product when choosing a method for controlling the grain size in special steel.

- Q: How does special steel contribute to the thermal conductivity of products?

- The unique composition and properties of special steel significantly enhance the thermal conductivity of products. By incorporating specific alloying elements like chromium, nickel, molybdenum, or vanadium, the thermal conductivity of special steel is improved. These alloying elements increase the free electron density within the steel, facilitating efficient heat transfer. The presence of alloying elements in special steel improves its lattice structure, enabling better heat transfer. The increased free electron density allows for quick and efficient movement of thermal energy through the material. Consequently, special steel effectively conducts heat from one area to another, making it suitable for applications requiring high thermal conductivity. Moreover, special steel undergoes advanced techniques like heat treatment, forging, or rolling, which further optimize its properties. These processes refine the microstructure, reducing impurities and enhancing thermal conductivity. As a result, the resulting steel product exhibits improved heat transfer capabilities and offers efficient thermal management. The remarkable thermal conductivity of special steel makes it highly sought after in various industries and applications. It finds extensive use in manufacturing heat exchangers, boilers, furnaces, and other thermal equipment where efficient heat transfer is crucial. Additionally, special steel is commonly employed in electrical appliances such as stovetops or induction cookers, where rapid and uniform heat distribution is necessary. To sum up, special steel enhances the thermal conductivity of products by utilizing specific alloying elements and advanced processing techniques. Its high thermal conductivity makes it invaluable in various industries, ensuring efficient heat management and optimal performance of thermal equipment and appliances.

- Q: What is the role of heat treatment in special steel?

- The role of heat treatment in special steel is to enhance its mechanical properties and improve its performance by altering its microstructure through controlled heating and cooling processes. This helps to achieve desired properties such as increased hardness, strength, toughness, and ductility, as well as improved wear resistance and corrosion resistance. Heat treatment also allows for the refinement of grain structure, elimination of internal stresses, and modification of the steel's crystalline structure, which ultimately improves the overall quality and usability of special steel in various applications.

- Q: How does special steel perform under extreme temperatures?

- Special steel is specifically designed to perform well under extreme temperatures. It exhibits excellent strength, hardness, and resistance to heat, making it highly suitable for applications that involve extreme heat or cold. At high temperatures, special steel maintains its structural integrity, which means it does not undergo significant deformation or loss of strength. It retains its hardness and dimensional stability, ensuring that it can withstand the extreme conditions without compromising its performance. Special steel also demonstrates exceptional resistance to thermal expansion and contraction, which is crucial when exposed to extreme temperature changes. This property allows the steel to expand and contract uniformly, minimizing the risk of cracking or other forms of damage. Moreover, special steel possesses excellent heat resistance, enabling it to retain its mechanical properties even at elevated temperatures. It exhibits high creep resistance, which is the ability to resist deformation under constant stress at high temperatures. This ensures that the steel can withstand prolonged exposure to extreme heat without experiencing failure or degradation. In addition to its impressive performance at high temperatures, special steel also performs well under extremely low temperatures. It maintains its toughness and ductility, with minimal risk of embrittlement or cracking. This makes it suitable for applications in cryogenic environments, such as in the aerospace or medical industries. Overall, special steel is designed to excel under extreme temperatures, offering exceptional strength, hardness, and resistance to heat. Its ability to maintain its structural integrity, resist thermal expansion and contraction, and withstand high or low temperatures makes it a reliable choice for various demanding applications.

- Q: What are the different construction grades of special steel?

- In various industries and applications, special steel with different construction grades is utilized. These grades are specifically engineered to offer superior strength, durability, and resistance to corrosion and other environmental factors. Some well-known construction grades of special steel include: 1. Mild Steel: This grade is widely used in construction and is considered the most basic. It has a low carbon content, making it easy to work with and weld. Mild steel is suitable for applications that require moderate strength and durability. 2. High-Strength Low-Alloy (HSLA) Steel: HSLA steel is a type of special steel that contains small amounts of alloying elements like copper, nickel, and vanadium. This grade provides higher strength and improved formability compared to mild steel. It is commonly used in structural applications where a higher strength-to-weight ratio is needed. 3. Weathering Steel: Also referred to as Cor-Ten steel, weathering steel is a special grade that develops a protective layer of rust when exposed to the elements. This layer acts as a barrier against further corrosion, making it ideal for outdoor structures. Weathering steel is commonly used in bridges, buildings, and other architectural applications. 4. Stainless Steel: Stainless steel is a corrosion-resistant alloy that contains at least 10.5% chromium. It offers exceptional resistance to corrosion, heat, and chemicals, making it suitable for a wide range of construction applications. Stainless steel is commonly used in building facades, roofing, and structural components. 5. Tool Steel: Tool steel is a special grade specifically designed for manufacturing tools, dies, and molds. It possesses high hardness, wear resistance, and toughness properties, making it suitable for applications that involve cutting, shaping, and forming materials. 6. Alloy Steel: Alloy steel is a special grade that incorporates additional alloying elements like manganese, silicon, nickel, and chromium. This grade provides enhanced strength, toughness, and wear resistance compared to carbon steel. Alloy steel finds common usage in machinery, equipment, and components subjected to high stress and wear. These examples highlight the various construction grades of special steel. Each grade possesses unique properties and is chosen based on the specific requirements of the application.

- Q: Can special steel be used for making chemical processing equipment?

- Indeed, chemical processing equipment can indeed be manufactured using special steel. It is common practice to opt for special steels, such as stainless steel, for such purposes due to their remarkable ability to resist corrosion, endure high temperatures, and exhibit durability. Given that chemical processing equipment frequently encounters corrosive substances, operates under extreme temperatures and pressures, it becomes imperative to employ materials that can withstand these demanding conditions. Special steel alloys are specifically engineered to possess exceptional resistance to corrosion, including resistance to acids, alkalis, and other aggressive chemicals. Furthermore, these steels are able to maintain their mechanical properties even when subjected to elevated temperatures, thereby ensuring the equipment's integrity and safety. Consequently, special steel emerges as an appropriate choice for the production of chemical processing equipment.

- Q: What are the specific requirements for special steel used in the railway track industry?

- The specific requirements for special steel used in the railway track industry include high strength, durability, and resistance to wear, fatigue, and corrosion. It must also possess good weldability and maintain its mechanical properties under varying temperatures and loading conditions. Additionally, the steel should comply with specific industry standards and undergo rigorous testing and quality control measures to ensure its reliability and safety for railway track applications.

Send your message to us

8-650mm CK45 Steel Bar / 1045 Round Steel / S45C Steel Rod

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords