7um Aluminum Laminated With 12um MPET and PE for Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of 7um Aluminum Laminated With 12um MPET and PE for Packing:

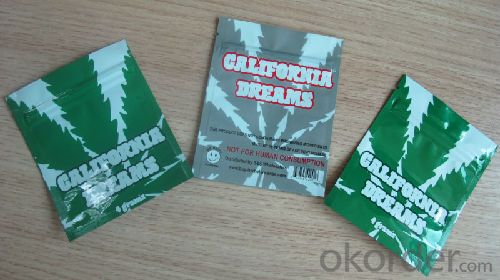

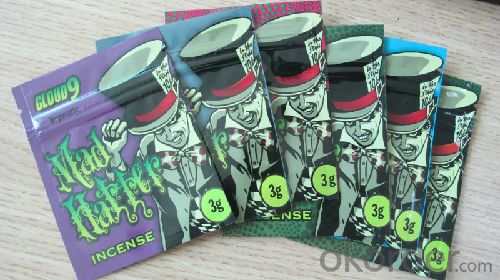

Laminated Aluminum With Plastic Packing Film Color Printed For Herbal Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Laminated Aluminum With Plastic Packing Film Color Printed For Herbal Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Of 7um Aluminum Laminated With 12um MPET and PE for Packing:

Excellent quality control

Experienced factory produced

SGS passed

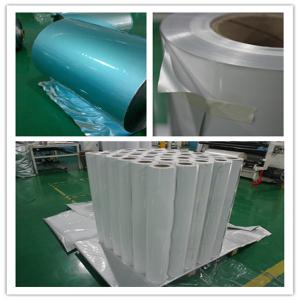

3.7um Aluminum Laminated With 12um MPET and PE for Packing Photos:

4.7um Aluminum Laminated With 12um MPET and PE for Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of 7um Aluminum Laminated With 12um MPET and PE for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Most importantly, the design of this package has a direct sensory connection to this product. Let's take a simple example, moon cake, which is a more common packing, is packed in a plastic bag and can only buy a few dollars, but it will appreciate a lot more when it is put into the gift box. It's in the bag. Moon cake is just food. In the gift box, it becomes a gift. Before consumers buy, the product is analyzed as a food or a gift, which is the most important message that the mooncake package conveys to the consumer.

- Q: What are the characteristics of a good package?

- This mainly refers to the packaging can perfectly protect and preserve the product design in the material selection, structure, can effectively cooperate with transportation storage loading and unloading circulation operation; the consumer, carrying the goods, convenient preservation.

- Q: Can food wrap be heated in a microwave oven?

- There are two sides to consider1. sealed pockets are heated in a microwave oven, and the pressure in the bag is too large to explode! There are all the instructions on the microwave (as well as the eggs, and a hole). The microwave food I eat is also packed in plastic bags, but there's always room for gas2. material of packing bagGeneral contact with food bags, requirements are made of polyethylene (non-toxic, burning candles oil smell), general temperature 130 degrees, this pocket no problem (including the regular supermarket to buy plastic wrap and plastic wrap)However, there are a lot of cheap pocket (for example in the market and vest bag, supermarket cashier for plastic bags) are made of PVC, and can not contact with recycled plastic food; do not to mention (characteristics: cheap, taste, burning acrid smell)And, if it's made of polyethylene, don't heat it up with high oil food

- Q: The vacuum packing bag is sealed. How can I open the zipper?

- In addition to wax, you can also use lubricating oil, to pick a relatively transparent, clean kind of, in the zipper ring drop a few drops, repeated several times, can also achieve smooth purposes.

- Q: What are the soft and hard sides of plastic bags? Material or process technology?

- The quality of plastic packaging is determined by both the material and the process. The material is no better than the good one. But the hardness of plastic is not a decisive factor in determining the quality of plastic, mainly to see what the use of what needs to keep products

- Q: Printing process of packaging bag

- When printing, through the extrusion of the scraper, the ink is transferred to the substrate through the mesh of the image part, so as to form the same picture and text as the original. The screen printing equipment is simple and easy to operate. The printing and plate making process is simple, low cost and adaptable. Printing screen printing application scope is broad common: color paintings, posters, name card is designed to cover commodity signs and textile printing and dyeing etc.

- Q: Is there any identification on the vacuum package?

- Laser inkjet printer, laser energy generator is the product surface engraved characters.

- Q: Why is the higher the elevation, the more food bags inflate? From a physical point of view

- The higher the altitude, the less the atmosphere, the smaller the pressure, and the pressure in the food package is a fixed value. The reason for the swelling of food packaging bags is that the pressure inside the food bags is greater than the external pressure!

- Q: Printing solvent for food packing bag

- Determine the amount of water in the solvent by means of the principle of a different dissolution effect. Take the most transparent glass cylinder tube with 100ml toluene solution, take a small amount of analyte ester solvent such as toluene, evenly pour. When you just pour in toluene, carefully observe whether there is turbidity (milk white) phenomenon. If there is this phenomenon, the water content of the solvent is seriously exceeded, and the experience shows that when the moisture content exceeds 0.5%, the phenomenon is obvious. The water content test of benzene solvent can be carried out by extracting solvent from the long glass tube to observe whether there is delamination.

- Q: What ink is the food packing bag printed on?

- 1, ink contains toluene, printed products residual solvent value is higher;2, chlorinated polypropylene heat stability is poor, easy to release chlorine, and in the air to form hydrogen chloride (commonly known as hydrochloric acid), making the ink showing a strong acid, the printing roll corrosion;3, benzene soluble ink can also release ozone depleting substances, in the process of production and use, it may produce damage to the production worker body, at the same time in the finished product is easy to residues of harmful substances, so the food packaging bag to cause pollution;

Send your message to us

7um Aluminum Laminated With 12um MPET and PE for Packing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches