Biaxial Geogrids - 50kn/m PP Biaxial Geogrid for Highway with CE Certificates

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

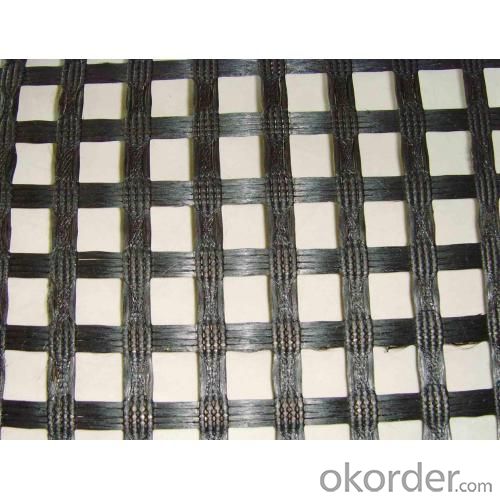

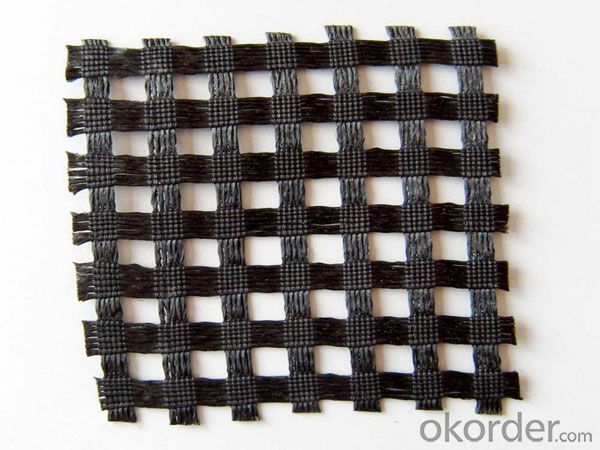

Structure of Pp Biaxial Geogrid:

Pp Biaxial Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of Pp Biaxial Geogrid :

fiberglass geogrid for soil reinforcement

fiberglass geogrid

Working & load transfer platforms

Reinforcement of the surface of road and bridge.

High tensile strength, low elongation

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

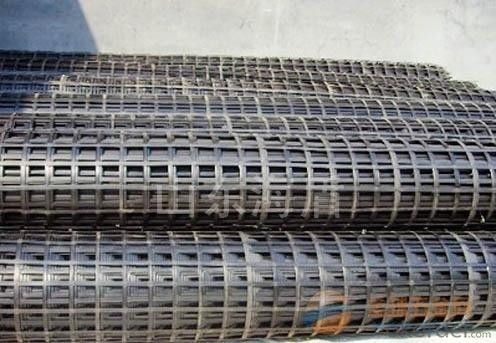

Pp Biaxial Geogrid Images

Pp Biaxial Geogrid Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: What are the criteria for the use of plastic geogrid

- Each grid has a variety of specifications, the specific reference to the national standard requirements, but the specifications are not necessarily the same as the national standard.

- Q: Geotextiles for geotextiles - Specification for geotextiles

- 5Protective effect of 6. It has the following characteristics as non-woven geotextile has more than six functions, so it can be widely used in railway, highway, sports venues, dams, water conservancy construction, tunnel, coastal beach reclamation, environmental engineering,. The application of the field of water conservancy engineering geotextile: Seawall dyke Lake embankment projecttarget reservoir; reinforcement; reclamation project; flood control. Highway and railway port engineering: soft foundation reinforcement treatment; slope protection; pavement anti reflection crack structure layer; drainage system; green isolation belt. Electrical engineering: nuclear power plant foundation engineering; thermal power ash dam project; hydropower station project. Port and Waterway Engineering: the performance and application of the port geomembrane: the product has excellent filtration, drainage, isolation, reinforcement, protection. Can be widely used in railway, highway, water conservancy construction, sports hall, dam, tunnel, coastal beach, Ken, environmental protection, power plant, around the airport project.

- Q: How do geogrids improve the performance of asphalt pavements?

- Geogrids improve the performance of asphalt pavements by providing reinforcement and stability. They effectively distribute the load across the pavement structure, reducing cracking and rutting. Additionally, geogrids enhance the overall strength and durability of the pavement, thus extending its lifespan and reducing maintenance costs.

- Q: Do geogrids affect the permeability of soil?

- Yes, geogrids can affect the permeability of soil. Geogrids are commonly used as reinforcement materials in civil engineering projects to improve the stability and load-bearing capacity of soils. By distributing the applied loads over a larger area, geogrids reduce the pressure on the soil particles, which can minimize soil compaction and increase the void space within the soil. This can enhance the permeability of the soil, allowing water to flow more freely through it. Therefore, geogrids can have a positive impact on the permeability of soil.

- Q: Are geogrids suitable for reinforcement of steep slopes?

- Yes, geogrids are suitable for reinforcement of steep slopes. Geogrids are high-strength materials that can be used to stabilize slopes and prevent erosion by providing mechanical reinforcement. They are effective in increasing the stability and load-bearing capacity of steep slopes, making them an ideal solution for slope reinforcement projects.

- Q: What are the factors that affect the long-term creep behavior of geogrids?

- The factors that affect the long-term creep behavior of geogrids include the type and quality of material used in the geogrid, the load applied on the geogrid, the duration and frequency of the load, the temperature and environmental conditions, and the installation and construction techniques employed.

- Q: What is the lowest price of two-way Plastic Geogrid

- You need to look at how much the kn

- Q: What is the road geogrid

- Classified editingPlasticAfter stretching form a square or rectangular net polymer material, according to the manufacture of the tensile direction for different uniaxial tension and biaxial tension. It is two in the polymer sheet by extrusion (the raw material is polypropylene or high-density polyethylene) on the hole, and then the implementation of directional tension in the heating conditions. Tension only along the length direction grid sheet tension; biaxial stretching grille is to continue the grille of one-way drawing again with its length in the direction perpendicular to the tensile material.Because of the polymer plastic geogrid in the manufacture of polymers with heating process and rearrange the directional extension, strengthen the contact force between molecular chains, to improve its strength. The elongation rate of only 10% to 15%. if the original sheet in geogrid with carbon black and ageing resistant material, can make it has good acid and alkali resistance, corrosion resistance and ageing resistance and durability.

- Q: Geogrid tgsg50-50 what does it mean

- That is, pull, 45KN, I am a manufacturer, geogrid TGSG45-45, two-way plastic geogrid 45KN, I hope to help you.

- Q: What are the factors to consider when selecting a geogrid for a specific application?

- When selecting a geogrid for a specific application, there are several factors to consider. These include the required strength and stiffness of the geogrid, the type of soil or aggregate it will be used with, the expected loads and stresses that will be applied, the environmental conditions such as temperature and moisture, and the installation and construction methods. Additionally, factors such as cost, durability, and availability should also be taken into account when choosing the most suitable geogrid for the application.

Send your message to us

Biaxial Geogrids - 50kn/m PP Biaxial Geogrid for Highway with CE Certificates

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords