5052 H32 High Quality Aluminum Fin Heat Exchanger Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Fin Heat Exchanger Coils Description:

Alloy Aluminium Plate 1200 is widely used in the strength requirements of the product. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminum Fin Heat Exchanger Coils:

PVC Protect Film

Waterproof paper

High Quality

Competitive Price

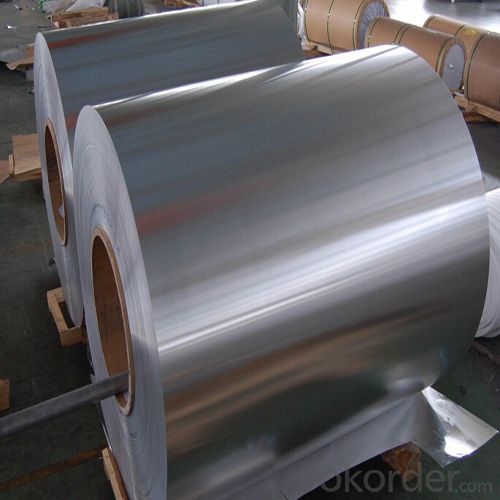

3. Aluminum Fin Heat Exchanger Coils Images:

4. Aluminum Fin Heat Exchanger Coils Specification:

Standard | GB/T3190-2008, GB/T3880-2006, ASTM B209, JIS H4000-2006 .etc |

Thickness | 0.2-200mm aluminium 5050 H38 |

Width | 1250mm 1000mm or as your requirements |

Length | 3000mm 5800mm or as your requirements |

MOQ | 5 Ton |

Package | Standard export package, by wooden box or as require |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum coils be painted or coated with different colors?

- Yes, aluminum coils can be painted or coated with different colors. Aluminum is a versatile material that can be easily painted or coated to achieve the desired aesthetic appearance. The coil can be pre-painted or coated before it is formed into the desired shape, or it can be painted or coated after it has been formed into the desired shape. The paint or coating can be applied using various methods such as spraying, rolling, or dipping. Additionally, there are various types of paint or coating options available, including powder coating, liquid paint, or even anodizing, which can provide different colors, finishes, and levels of durability. Overall, painting or coating aluminum coils is a common practice to enhance their appearance and protect them from corrosion or other environmental factors.

- Q: My dad saw an alternative medicine practioner who said he had high levels of aluminum in his blood ... from using aluminum cookware. She said this was causing the shortness of breath and dizziness he was experiencing. Since he has stopped using aluminum cookware, he is now fine. He saw regular doctors, and nobody else could figure out what was wrong with him. Has anyone else out there had any experience with this?

- No but alumimun cookware can cause Alzheimer's

- Q: Is there a system or initiative in place for recycling aluminum coils?

- <p>Yes, there are recycling programs for aluminum coils. Many recycling centers accept aluminum coils, and some manufacturers have their own recycling programs. Aluminum is highly recyclable, and recycling it saves energy and resources. To recycle aluminum coils, you can contact local recycling facilities or check with the manufacturer for specific programs. Some regions also have e-waste recycling programs that may accept aluminum coils from electronic devices. It's important to clean and prepare the coils for recycling to maximize their value and recyclability.</p>

- Q: When you are cooking fish? I ran out of aluminum foil, all I have is parchment paper on hand. Does it matter or affect the way the fish gets cooked? Just wondering what the difference is, if any.

- The fish should cook fine in the parchment paper - it could be even better that way.

- Q: What are the necessary safety measures to take when handling aluminum oxide coated aluminum coils?

- <p>When working with aluminum oxide coating on aluminum coils, it's crucial to follow safety precautions. Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask to prevent inhalation of dust particles. Ensure proper ventilation to avoid dust accumulation. Handle the material carefully to prevent any skin contact with the coating. Keep the area clean and free from any flammable materials to avoid fire hazards. Be aware of the specific health risks associated with aluminum oxide exposure, and follow the manufacturer's guidelines for safe handling. Regularly inspect equipment for any signs of wear or damage that could lead to accidents.</p>

- Q: My favorite deodorant contains aluminum. It smells really good and it works really well.My mom doesn't like me using it because it contains aluminum.So I got aluminum free. It doesn't smell at all (I can't seem to find fragrant aluminum free deodorant) and it doesn't work as well, for some reason.I want to keep using the one with aluminum, but will it be harmful to me in the future?

- aluminum is an antiperspirant so it stops you from sweating. if you don't have a wetness problem you could just use regular deodorant check out Jason's natural products or kiss my face cosmetics

- Q: What does 1060 stand for in 1060 aluminum rolling?

- It means the aluminum content should be above 99.6%.

- Q: How do aluminum coils contribute to the aesthetics of architectural designs?

- Aluminum coils play a significant role in enhancing the aesthetics of architectural designs. One of the main reasons is their versatility in terms of shape and size. Aluminum coils can be easily formed into various shapes, making them suitable for a wide range of architectural applications. The lightweight nature of aluminum coils also contributes to their aesthetic appeal. They provide a sleek and modern look to buildings, especially when used in cladding or façade systems. The use of aluminum coils can create a visually pleasing and contemporary appearance, adding a touch of elegance to the overall design. Additionally, aluminum coils offer a wide range of color options, thanks to their ability to be coated or painted. This allows architects and designers to choose from an extensive palette of colors, enabling them to match the building's exterior with its surroundings or to create a specific mood or theme. The color choices available for aluminum coils provide endless possibilities for customization and creativity in architectural design. Furthermore, aluminum coils are highly durable and resistant to corrosion, making them suitable for long-lasting architectural applications. Their ability to withstand harsh weather conditions ensures that the building's aesthetics remain intact over time. This durability factor is essential in maintaining the visual appeal of architectural designs, as it prevents the need for frequent repairs or replacements. In summary, aluminum coils contribute to the aesthetics of architectural designs through their versatility, lightweight nature, color options, and durability. Their ability to be shaped into various forms, combined with a wide range of color choices, allows architects and designers to create visually stunning and customized buildings. The sleek and modern appearance of aluminum coils adds a touch of elegance to architectural designs, enhancing their overall aesthetics.

- Q: Are aluminum coils suitable for pharmaceutical vial caps?

- Pharmaceutical vial caps can indeed be made from aluminum coils. When it comes to pharmaceutical packaging, aluminum is highly favored thanks to its exceptional barrier properties. These properties effectively shield the vials' contents from moisture, oxygen, and other harmful substances. Aluminum coils can be easily molded into caps of various sizes and shapes, accommodating different types of vials. Another advantage is that aluminum is a lightweight material, which makes transportation and handling hassle-free. Additionally, aluminum is resistant to corrosion, ensuring that the vial caps remain intact throughout storage and usage. In summary, due to their barrier properties, versatility, and durability, aluminum coils are a suitable option for pharmaceutical vial caps.

- Q: What are the different surface textures available for aluminum coils?

- There are several different surface textures available for aluminum coils, including smooth, brushed, embossed, and stucco. These textures provide varying levels of aesthetic appeal and functionality, allowing for customization and versatility in various applications.

Send your message to us

5052 H32 High Quality Aluminum Fin Heat Exchanger Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords