409 410 stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

410 and 430 stainless steel sheet

1.Description of products

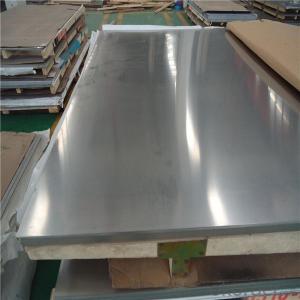

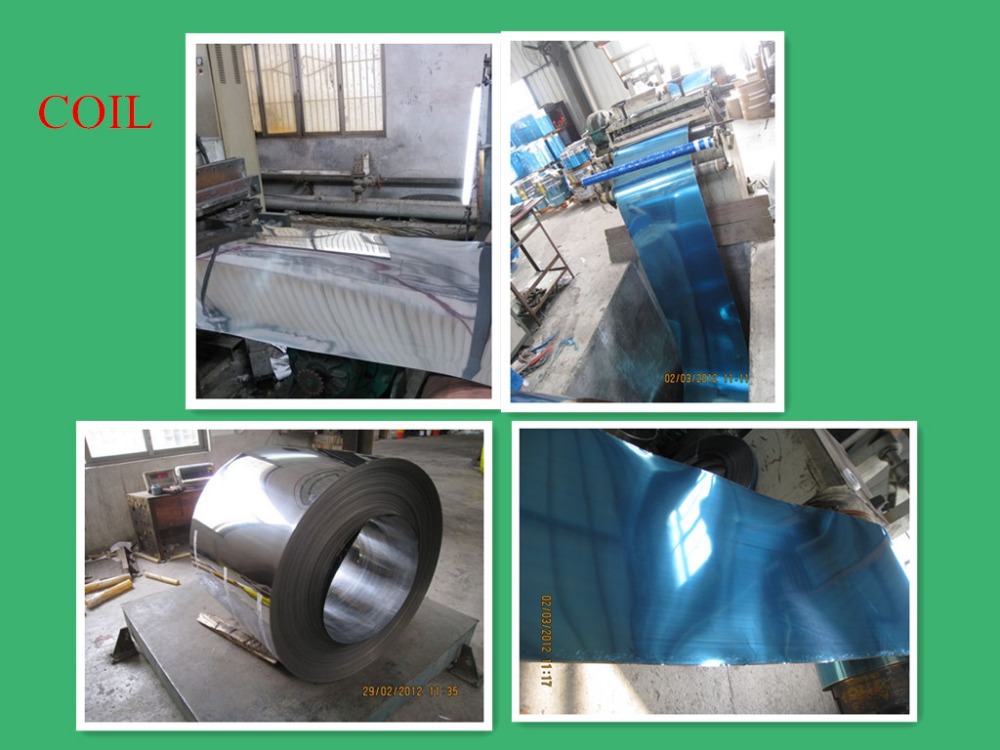

| Item: | Cold rolled stainless steel coil |

| Grade: | 410 430 |

| Standard: | JIS,AISI,ASTM,GB,DIN, |

| Thickness: | 0.16mm-2.0mm |

| Width: | max:1080mm |

| Place of Orgin: | Jieyang,China(Mainland) |

| Brand name: | baosteel , lisco,tisco,jisco |

| Type: | Plate,Coil,Circle,Sheet |

| Application: | Building ,household appliance. kitchen utensiles, industry and medical equipment,electric cooker etc. |

| Technical processing: | Cold rolled |

| Surface: | BA, 8K ,NO.4, mirror, hairline according to customer's request. |

| Certificate: | the third inspections |

| Port: | SHENZHEN, SHANTOU |

| Packaging Details: | Export standard package |

| Delivery Time: | About 10-30 days |

| Payment Terms: | T/T,Irrevocable L/C at sight,D/P |

| Supply Ability: | 2500Ton-3000Ton/per Month |

2. Products

Application

Building, elevator decoration,

household appliance. kitchen utensiles

6.Tips

If you are interested in our products,please tell us about the type,finish,size,thickness ,QTY and terms of shipment so that we can make an exact and favorable quotation for you.

Our philosophy:“Quality First”, advanced equipments together with experienced technicians ,hope we will have a chance to work for you,welcome to inquiry.

- Q: Can stainless steel sheets be used in food processing industries?

- Yes, stainless steel sheets are commonly used in food processing industries due to their excellent corrosion resistance, hygiene, and durability. The smooth and non-porous surface of stainless steel makes it easy to clean and maintain, ensuring sanitary conditions. Additionally, stainless steel is resistant to chemicals and can withstand high temperatures, making it suitable for various food processing applications such as equipment, storage tanks, and work surfaces.

- Q: How do I prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, it is important to regularly clean and maintain them. Use a soft cloth or sponge along with mild soap or a stainless steel cleaner to remove any dirt or grime. Avoid using abrasive cleaners or scrubbing pads, as they can scratch the surface. Additionally, be cautious of exposing stainless steel sheets to harsh chemicals or acidic substances, as they can cause discoloration.

- Q: Are stainless steel sheets suitable for automotive grilles or trim?

- Yes, stainless steel sheets are suitable for automotive grilles or trim due to their durability, corrosion resistance, and ability to withstand harsh weather conditions.

- Q: What's the difference between stainless steel 304 and stainless steel 202?

- After pickling of stainless steel, surface color silver finish: chromium nickel stainless steel color white jade is white; chromium stainless steel slightly weak light Ze; CrMnN Stainless steel and chromium nickel stainless steel similar color is slightly lighter. The surface color: stainless steel pickling chrome nickel steel is brownish black brown and white; chromium; chromium manganese nitrogen is black, (these three kinds of color, refers to the oxidation of the heavier color). Cold rolled unannealed chromium nickel stainless steel, silver reflective surface. Stainless steel, except for steel, is usually pickled and white.

- Q: Can stainless steel sheets be used in the medical industry?

- Stainless steel sheets have the capability of being utilized within the medical industry. This is because stainless steel is a favored material within the medical field due to its exceptional resistance against corrosion, its remarkable strength, and its ability to endure. It is commonly employed for a diverse array of purposes, encompassing medical instruments, surgical tools, dental equipment, implants, and medical machinery. Moreover, stainless steel sheets are uncomplicated to cleanse and sterilize, rendering them perfect for maintaining hygienic conditions within medical settings. Furthermore, stainless steel is biocompatible, signifying that it is harmonious with human tissues and does not elicit any unfavorable reactions, thereby making it a secure option for medical applications. All in all, stainless steel sheets are exceedingly appropriate for usage within the medical industry due to their myriad advantageous qualities.

- Q: What are the different types of surface finishes for stainless steel sheets?

- Stainless steel sheets come in a variety of surface finishes, each with its own unique characteristics and appearances. Here are some of the most commonly used finishes: 1. The No.1 Finish, also known as hot rolled or annealed finish, is the most basic stainless steel finish. It has a rough, dull appearance with visible grain lines. This finish is typically used for industrial applications where aesthetics are not a priority. 2. The No.2B Finish is achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. This results in a bright, smooth finish with a semi-reflective appearance. It is often used for kitchen appliances, decorative trim, and architectural purposes. 3. The No.4 Finish is obtained by brushing the stainless steel sheet with abrasive materials, giving it a uniform, satin-like appearance. It is popular in commercial kitchens, elevator panels, and decorative applications that require a visually appealing and easy-to-clean surface. 4. The No.8 Mirror Finish is the most reflective surface finish available for stainless steel sheets. It involves polishing the surface to a mirror-like shine using progressively finer abrasives. This finish is commonly seen in decorative applications like architectural features, automotive trim, and jewelry. 5. The Hairline Finish is achieved by sanding the stainless steel sheet with fine abrasives in a consistent linear pattern. This creates a textured, brushed appearance and is often used for decorative purposes such as wall cladding, furniture, and signage. 6. The Bead Blasted Finish is achieved by bombarding the stainless steel sheet with small glass beads at high pressure, resulting in a uniform, matte texture. It is commonly used in architectural applications like column covers, elevator doors, and facade panels. These are just a few examples of the different surface finishes available for stainless steel sheets. Each finish offers its own visual effects, textures, and levels of reflectivity. The choice of finish depends on the desired aesthetic, functionality, and requirements of the application.

- Q: What are the benefits of using patterned stainless steel sheets in interior design?

- Patterned stainless steel sheets offer several benefits in interior design. Firstly, they add visual interest and uniqueness to a space, allowing for creative and innovative design possibilities. The patterns can range from subtle to bold, providing options to suit various aesthetics and design themes. Additionally, stainless steel is a durable material that is resistant to corrosion, making it ideal for high-traffic areas or spaces prone to moisture. It is also easy to clean, making maintenance hassle-free. The reflective properties of stainless steel can also help to brighten a room and create an illusion of increased space. Furthermore, patterned stainless steel sheets are versatile and can be used in various applications, such as wall coverings, backsplashes, countertops, or even furniture accents. They can be used to enhance both modern and traditional interior designs, adding a touch of sophistication and elegance. Overall, the benefits of using patterned stainless steel sheets in interior design include their aesthetic appeal, durability, ease of maintenance, versatility, and ability to enhance the overall visual appeal of a space.

- Q: Are stainless steel sheets resistant to acetic acid?

- Yes, stainless steel sheets are generally resistant to acetic acid. Acetic acid is a weak acid and does not cause significant corrosion or damage to stainless steel. However, prolonged exposure to highly concentrated or boiling acetic acid may cause some corrosion or staining on the surface of the stainless steel. It is important to note that the resistance of stainless steel to acetic acid can vary depending on the specific grade and composition of the stainless steel.

- Q: What is the abrasion resistance of stainless steel sheets?

- The abrasion resistance of stainless steel sheets is generally considered to be high. Stainless steel is known for its durability and hardness, making it resistant to wear and tear caused by friction or contact with abrasive materials. The specific level of abrasion resistance can vary depending on the grade and finish of the stainless steel sheet, as well as the specific application it is being used for. However, in general, stainless steel sheets are known to have excellent resistance to scratches, scuffs, and other forms of abrasion, making them a popular choice for various industries where durability and longevity are important factors.

- Q: Can stainless steel sheets be used for medical instrument trays?

- Yes, stainless steel sheets can be used for medical instrument trays. Stainless steel is a common material used in medical settings due to its durability, resistance to corrosion, and ease of cleaning. It is suitable for maintaining a sterile environment and can withstand repeated sterilization processes without degrading.

Send your message to us

409 410 stainless steel sheetsCold rolled/hot rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords