4 X 8 Film Faced Plywood Sheets for Construction Formwork

- Ref Price:

-

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 3000 m³/month

Add to My Favorites

Follow us:

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Specification

Type:

Film Faced Plywood

Application:

For Construction

Packaging & Delivery

| Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

|---|

| Delivery Detail: | 30days after receiving LC or deposit |

|---|

Specifications

film faced plywood

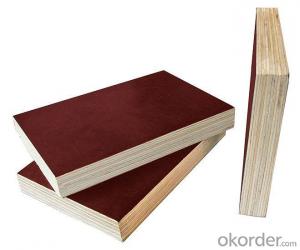

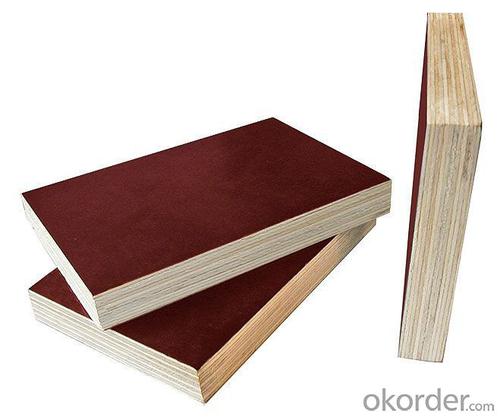

1)size:1220x2440mm

2)F/B:brown,black,red

3)core:poplar,combi,hardwood

4)glue:WBP,melamine,MR

Product Name | Film faced plywood |

F/B | Black film, brown film, anti-slip film |

Grade | First grade |

Core | Poplar, hardwood, birch, pine, combi , and so on |

Glue | MR WBP |

Thickness | 8-21mm |

Specification | 1220x2440mm, 1250x2500mm, |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB, CIF,CNF |

Payment | T/T, 100% irrevocable LC |

Delivery Time | Within 15 days after order confirmed |

Supply Capacity | 3000CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce techniqueCredit first, fair trading |

No | Property | Unit | Test Standard | Value of Test | Result |

1 | Moisture content | % | EN322 | 8-12 | Check out |

2 | Density | Kg/m3 | EN322 | 560 | Check out |

3 | Bonding quality | Bonding quality | Mpa | EN314 | Max:1.72 Min:0.85 | Check out |

Damage rate | % | GB/T17656-1999 | 60% |

4 | Bending modules of elasticity | Longitudinal | Mpa |

EN310 | 6800 | Check out |

Lateral | 5920 |

5 | Bending strength(N/mm) | Longitudinal | 63 | Check out |

Lateral | 48 |

6 | Cycle Life | About 12-25 repeated using times according projects by formwork application

|

- Q: Plywood in the material defects?

- race of the parasitic plant marks of parasitic plants formed by the parasitic plants or rotten plants penetrate the wood and the formation of small groups of small channels

- Q: What is the general use of plywood in decoration works?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- the minimum number of layers of each nominal thickness to comply with the relevant provisions.

- Q: Why plywood is cheaper than solid wood

- Without changing the physical properties of wood under the premise of drying, liposuction, paint and other processes can be called solid wood. Plywood (English: Plywood,

- Q: What harm does the plywood factory work?

- Occupational acute benzene poisoning is the workers in the professional activities, short-term inhalation of high-dose benzene vapor caused by the central nervous system suppression as the main manifestation of systemic diseases

- Q: Ordinary plywood is divided into four categories

- Thickness specifications for the 6,9,12,15,18 and so on. The main performance indicators for the water content of 4 to 13%, the expansion of water thickness ≤ 12%, as well as tensile strength, bending strength, grip nail force.

- Q: What is the amount of construction works used for this plywood?

- A class of plywood for weather resistance, resistance to boiling water plywood, which and he has a durable, high temperature, the advantages of steam treatment;

- Q: What is a joinery board?

- The center plate of the blockboard should have the same direction of grain and perpendicular to the texture of the core.

- Q: Plywood quality requirements include appearance level, size, physical and mechanical properties of the three elements.

- Appearance level, size, physical and mechanical properties of the three tests are qualified to determine the product is a qualified product, or judged to be unqualified. P

- Q: What are the shortcomings of plywood

- A group of veneers are usually in the direction of adjacent layers of wood grain perpendicular to the formation of each other, usually its table and the inner plate symmetrically arranged in the center layer or plate on both sides