310s Stainless Steel Plate/Sheet with BA Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Plate 310S

Brand name :

Technique: hot rolled or cold rolled

Type : plate

Model number :310S(0Cr25Ni20/1Cr25Ni20Si2)

Thickness : Cold Rolled: 0.3-3, 4, 5,6mm; Hot rolled: 3-120mm

Width :1219mm/1500mm/1800mm or as request

Length : 2438/3000/6000mm, size can be customized

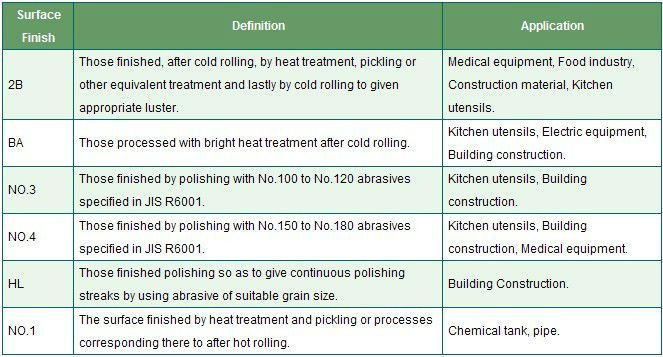

Finish: Cold Rolled: 2B, 2D, BA, NO.4, HL, 8K; Hot Rolled: NO.1, 4K, Polished.

Payment terms: T/T, 30% of value prepaid after signing S/C within three working days, and the balance against the copy of B/L.

Package :standard packing or at customer's request.

Standard :ASTM AISI GB

Certification: ISO

Applications :Widely used in the fields related to chemical equipment and heat resistant parts, and typecally applied in saggers, drying equipment, industrial furnace lining, heat-exchangers, petroleum refinery equipment, etc

TISCO China 310S stainless steel plate price per ton

GRADE | 310s | |

SURFACE | Cold Rolled :2B/NO.4/HL/BA/8K | Hot rolled :NO.1 |

WIDTH(mm) | 1000mm ,1219mm ,1250mm , 1500mm ,1600mm ,1800mm,2000mm ,2500mm etc. | |

THICKNESS(mm) | Cold Rolled :0.3mm,0.4mm,0.5mm,0.6mm,0.7mm, 0.8mm,0.9mm,1.0mm,1.2mm,1.5mm,2.0mm,2.5mm,3.0mm

Hot rolled :3.0mm ,4.0mm,5.0mm,6.0mm,8.0mm,10.0mm, 12.0mm,14.0mm,16.0mm,18.0mm,20.0mm,22.0mm,25.0mm, 28.0mm,30.0mm,32.0mm,35.0mm,38.0mm,40.0mm etc. | |

LENGTH(mm) | According to customer requirements | |

Surface finishes and characteristic

310s Chemical Composition | ||||||

C | Si | Mn | Cr | Ni | S | P |

≤0.08 | ≤1.00 | ≤2.00 | 24.0~26.0 | 19.0~22.0 | ≤0.030 | ≤0.035 |

mechanical properties:

Mechanical properties | |||||||

Heat Treatment | Yield strength(N/mm2) | Tensile strength | Elongation(%) | Hardness | |||

HB | HRB | HV | |||||

310S | S | ≥205 | ≥520 | ≥40 | ≤187 | ≤90 | ≤200 |

Surface finishes and characteristic

- Q: Are stainless steel sheets resistant to organic acids?

- Yes, stainless steel sheets are generally resistant to organic acids.

- Q: Are stainless steel sheets suitable for structural applications?

- Stainless steel sheets, indeed, prove to be appropriate for structural applications. This material, known for its versatility and durability, boasts a remarkable strength-to-weight ratio, rendering it highly suitable for diverse structural purposes. Its exceptional corrosion resistance is particularly vital for structures subjected to severe environmental conditions or chemical exposure. Utilizing stainless steel sheets in the fabrication of bridges, buildings, and other structural elements ensures the attainment of necessary robustness and longevity. Moreover, stainless steel stands as a sustainable choice due to its complete recyclability, thereby further augmenting its appropriateness for structural applications.

- Q: Are stainless steel sheets suitable for elevator wall panels?

- Indeed, elevator wall panels can be made from stainless steel sheets. The use of stainless steel is quite popular for such panels due to its strong and enduring nature, as well as its ability to resist corrosion. Given that elevators are areas with high foot traffic, it is crucial to select a material that can withstand constant usage and potential impact. Stainless steel sheets are resilient and can endure the wear and tear associated with elevator usage. Moreover, stainless steel possesses a remarkable resistance to corrosion, making it a suitable choice for environments that experience high humidity or exposure to chemicals. Furthermore, stainless steel adds a sleek and contemporary touch to the interior of elevators, enhancing their elegance. Overall, stainless steel sheets are a dependable and visually pleasing option for elevator wall panels.

- Q: Can stainless steel sheets be used for outdoor furniture?

- Yes, stainless steel sheets can be used for outdoor furniture. Stainless steel is a highly durable material that is resistant to rust, corrosion, and weathering. This makes it an ideal choice for outdoor furniture as it can withstand the elements and retain its appearance and structural integrity over time. Additionally, stainless steel has a sleek and modern look that can complement various outdoor design styles. Whether it's for tables, chairs, or other outdoor furniture pieces, stainless steel sheets can provide a long-lasting and visually appealing option for outdoor use.

- Q: Are stainless steel sheets suitable for water treatment facilities?

- Yes, stainless steel sheets are highly suitable for water treatment facilities. Stainless steel is known for its corrosion resistance, which is crucial in an environment where water and chemicals are constantly present. It is resistant to rust and degradation, ensuring the longevity and durability of the sheets. Additionally, stainless steel is easy to clean and maintain, making it an ideal choice for facilities that require regular hygiene and sanitation. The material is also highly resistant to heat and extreme temperatures, ensuring its performance even in demanding conditions. Moreover, stainless steel is non-reactive, meaning it does not release harmful substances into the water during treatment processes, making it safe and reliable for water treatment applications.

- Q: Are stainless steel sheets suitable for roofing?

- Yes, stainless steel sheets are suitable for roofing. They have excellent durability, corrosion resistance, and can withstand extreme weather conditions. Additionally, their sleek appearance adds aesthetic value to any building.

- Q: Can stainless steel sheets be used for architectural façades?

- Yes, stainless steel sheets can be used for architectural façades. Stainless steel is a popular choice for façade cladding due to its durability, corrosion resistance, and aesthetic appeal. It can be shaped, cut, and textured to create various design possibilities, making it suitable for a wide range of architectural styles. Additionally, stainless steel offers low maintenance requirements and longevity, making it a practical choice for architectural façades.

- Q: Is there a big price difference between the SUS304 stainless steel plate and the drawing plate?

- Wire drawing is the surface of a steel processing methods, 304 and 201 steel plates can be processed drawing, the price difference is not very large, it will be more than a processing fee. The steel plate after drawing is more likely to rust than the steel plate on the 2B surface.

- Q: What's the cheapest kind of stainless steel plate? What's the model and how much is it?

- Ferritic stainless steel (with magnetic) inside 409 minimum, average price of 7800 yuan / ton, including tax, the proportion of 7.75, the formula is the same as above

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- To prevent fretting corrosion on stainless steel sheets, there are several preventive measures that can be taken: 1. It is crucial to handle stainless steel sheets properly, avoiding any scratching or rubbing of the surface that could lead to fretting corrosion. Gloves should be worn and contact with other metals or rough surfaces should be avoided. 2. Regular cleaning of the stainless steel sheets using mild detergents or specialized stainless steel cleaners is recommended. This helps to remove contaminants that can initiate corrosion and prevents the build-up of dirt or grime that can contribute to fretting corrosion. 3. Applying a suitable lubricant or anti-seize compound on the contact surfaces can minimize friction and prevent fretting corrosion, especially in applications with repeated movement or vibration. 4. Whenever possible, it is advised to isolate stainless steel sheets from direct contact with other metals. This can be achieved by using insulating materials, gaskets, or non-metallic spacers to create a barrier between the stainless steel and potentially corrosive materials. 5. Regular inspection of the stainless steel sheets is important to detect any signs of fretting corrosion, such as small cracks, discoloration, or pitting. Early detection allows for prompt action to prevent further damage. 6. Applying a protective coating, such as a passivation treatment or a corrosion-resistant paint, can provide an additional layer of protection against fretting corrosion. It is recommended to consult with a professional to determine the most suitable coating for the specific application. 7. Proper storage of stainless steel sheets is essential. When not in use, they should be stored in a clean, dry environment to minimize exposure to moisture or corrosive substances. The storage area should be well-ventilated and free from any contaminants that could potentially initiate fretting corrosion. By following these preventive measures, the risk of fretting corrosion on stainless steel sheets can be significantly reduced, ultimately prolonging their lifespan.

Send your message to us

310s Stainless Steel Plate/Sheet with BA Surface

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords