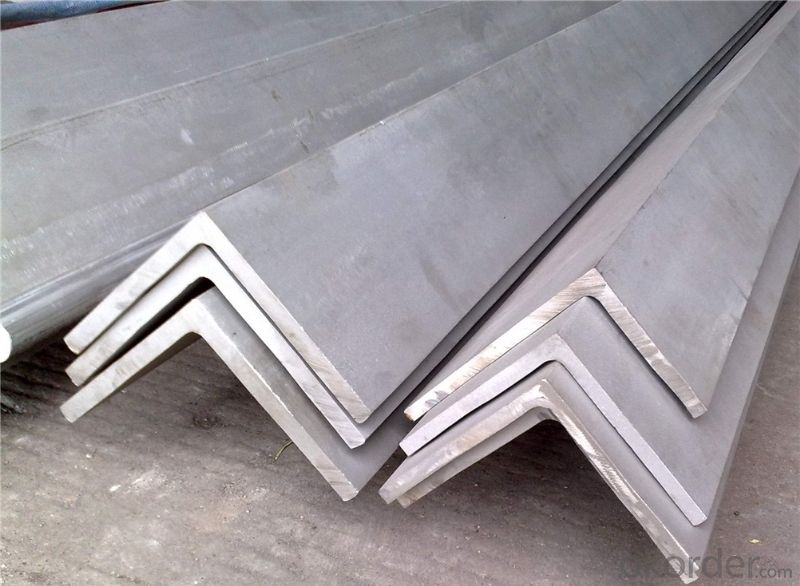

20mm*2.5mm hot sell Equal Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material |

Composition

Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | |||

Mo | 2.0-3.0 | ||||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253 | <253 | <200 | <200 | |||

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel angles be customized or fabricated to specific requirements?

- Yes, steel angles can be customized or fabricated to specific requirements. Steel angles are versatile and can be easily modified to meet different specifications and applications. Fabrication processes such as cutting, drilling, welding, and bending can be used to customize steel angles to the desired shape, size, and dimensions. This allows for the creation of steel angles with specific lengths, thicknesses, and angles to meet the unique requirements of different construction or engineering projects. Customized steel angles can be used in various applications, including structural framing, supports, brackets, reinforcements, and architectural designs. Overall, steel angles offer flexibility in customization and fabrication, making them suitable for a wide range of construction and industrial needs.

- Q: How do steel angles perform in extreme weather conditions?

- Steel angles are highly durable and resistant to extreme weather conditions. They can withstand high winds, heavy rains, and temperature fluctuations without losing their structural integrity. Their strength and stability make them an excellent choice for construction projects in areas prone to hurricanes, tornadoes, or harsh climates.

- Q: How are steel angles manufactured?

- Steel angles are typically manufactured through a process called hot rolling, where a steel billet is heated and passed through a series of rollers to give it the desired shape and dimensions. This process ensures that the angles have a consistent and uniform profile, making them suitable for various structural and construction applications.

- Q: Are there any limitations or restrictions on the use of steel angles in certain applications?

- Yes, there are limitations and restrictions on the use of steel angles in certain applications. One limitation is the maximum load-bearing capacity of the steel angles. Depending on the size, thickness, and quality of the steel angles, they may have a limited ability to support heavy loads. Therefore, in applications where high strength and load-bearing capacity are required, alternative structural members such as steel beams or columns may be more suitable. Another restriction is the suitability of steel angles for specific shapes or configurations. Steel angles are typically L-shaped, and while they are versatile and commonly used in various applications, they may not be ideal for certain complex or curved designs. In such cases, custom-shaped structural members or other materials may be more appropriate. Additionally, the corrosion resistance of steel angles is a limitation in certain environments. Steel is susceptible to rust and corrosion, particularly in marine or highly humid conditions. In applications where exposure to moisture or corrosive substances is inevitable, additional protective measures such as coatings or stainless steel angles may be required. Lastly, the fabrication and installation of steel angles may also impose limitations. Steel angles often require welding, cutting, or drilling during fabrication, which can be challenging in certain applications where precision and specialized equipment are necessary. Moreover, the size and weight of steel angles may pose limitations during transportation and installation, especially in confined spaces or areas with limited access. Therefore, it is crucial to consider these limitations and restrictions when selecting steel angles for specific applications, ensuring that they meet the required strength, shape, corrosion resistance, and installation requirements.

- Q: Are steel angles resistant to pests and insects?

- Yes, steel angles are resistant to pests and insects as they are not a food source and provide no habitat for them.

- Q: How do steel angles contribute to the energy efficiency of a building?

- There are multiple ways in which steel angles can enhance the energy efficiency of a building. To begin with, steel angles are commonly utilized as structural components during the construction of buildings. Their presence provides strength and support to the building's framework, enabling the incorporation of larger windows and open floor plans. This facilitates the entry of natural daylight, thereby diminishing the need for artificial lighting during the daytime and subsequently reducing energy usage. Moreover, steel angles have the ability to contribute to the creation of energy-efficient building envelopes. By integrating steel angles into the construction of walls, roofs, and floors, the occurrence of thermal bridging can be minimized. Thermal bridging refers to the escape or entry of heat in a building due to materials with high thermal conductivity, such as concrete or wood. By utilizing steel, which possesses low thermal conductivity, the transfer of heat is reduced, leading to an improvement in the overall thermal performance of the building envelope. Furthermore, steel angles can be employed for the installation of energy-conserving systems and equipment. For example, they can provide support for solar panels, which generate clean and renewable energy. Additionally, steel angles can be utilized in the installation of HVAC systems, promoting efficient air circulation and distribution throughout the building. By incorporating steel angles into these applications, the energy efficiency of the building is enhanced, resulting in decreased energy consumption and lower utility bills. To summarize, the utilization of steel angles significantly contributes to the promotion of energy efficiency in buildings. They provide structural integrity, help minimize thermal bridging, and support the installation of energy-conserving systems. By incorporating steel angles into the design and construction of a building, energy consumption is reduced, resulting in a more sustainable and cost-effective built environment.

- Q: Are there any environmental concerns related to the production or disposal of steel angles?

- There exist numerous environmental concerns in relation to the production and disposal of steel angles. To begin with, the production of steel angles necessitates substantial amounts of energy and raw materials, such as iron ore and coal. The extraction of these resources can result in detrimental effects on the environment, including habitat destruction, deforestation, and air and water pollution. Furthermore, the manufacturing process itself emits greenhouse gases and other pollutants, contributing to climate change and air pollution. Moreover, the disposal of steel angles can pose problems. Steel is not easily biodegradable and may take hundreds of years to decompose. Inadequate disposal methods, such as landfilling or incineration, can lead to the release of toxic substances and contribute to soil and water contamination. To address these environmental concerns, various measures can be implemented. Firstly, enhancing the efficiency of steel production processes can reduce energy consumption and emissions. The utilization of recycled steel in the production of steel angles can also aid in decreasing the demand for raw materials and minimizing environmental impacts. Additionally, the implementation of proper waste management and recycling programs can help minimize the environmental footprint of steel angle disposal. In conclusion, although steel angles are crucial in numerous industries and construction, their production and disposal can have significant environmental implications. It is vital to prioritize sustainable practices and technologies to mitigate these concerns and promote a more environmentally friendly approach to the production and disposal of steel angles.

- Q: What are the different types of steel angles connections?

- There are several different types of steel angle connections used in construction and engineering projects. Some of the most common types include: 1. Welded Connection: This is the most straightforward type of steel angle connection, where the angles are joined together using welding techniques. It provides a strong and rigid connection, but it requires skilled welders and can be time-consuming. 2. Bolted Connection: In this type of connection, the angles are connected by bolts, nuts, and washers. It allows for easier disassembly and modification, making it a popular choice for temporary structures or where future changes may be required. Bolted connections can be used with or without additional reinforcement, such as gussets or plates. 3. Riveted Connection: Riveting involves joining the angles using rivets, which are metal pins with a head on one end. Rivets are inserted into pre-drilled holes and then hammered to form a permanent connection. Although less common nowadays, riveted connections were widely used in older steel structures and bridges. 4. Clip Angle Connection: This type of connection involves using clip angles, which are small steel angles that are bolted or welded to the main angles. Clip angles provide additional support and reinforcement to the primary connection, enhancing its strength and stability. 5. Pinned Connection: Pinned connections allow for rotational movement between the angles, providing flexibility and allowing for load redistribution. They typically involve a pin or bolt passing through holes in the angles, allowing them to rotate freely. 6. Gusset Plate Connection: Gusset plates are flat steel plates that are used to connect and reinforce the angles. They are usually bolted or welded to the angles and provide additional strength and stability to the connection. The choice of steel angle connection depends on various factors such as the load-bearing requirements, structural design, ease of installation, and the need for future modifications. Each type has its advantages and disadvantages, and engineers select the most suitable connection type based on the specific project requirements.

- Q: Can steel angles be used for staircases?

- Yes, steel angles can be used for staircases. Steel angles are commonly used as structural supports in construction, including for staircases. They provide strength and stability to the staircase structure and can be designed to meet specific load-bearing requirements.

- Q: Can steel angles be used as reinforcement in concrete structures?

- Yes, steel angles can be used as reinforcement in concrete structures. Steel angles are often used as L-shaped or angle-shaped bars that are embedded within the concrete to provide additional strength and support to the structure. These angles help to resist tensile forces and prevent cracking or failure of the concrete. They are commonly used in applications such as beams, columns, and walls to enhance the structural integrity and load-bearing capacity of the concrete elements. Additionally, steel angles can be easily welded or bolted together, making them a versatile and cost-effective choice for reinforcement in concrete structures.

Send your message to us

20mm*2.5mm hot sell Equal Angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords