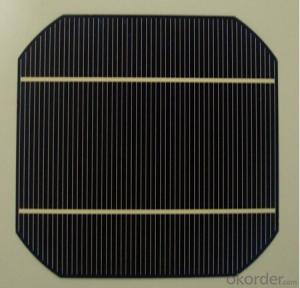

125mm Mono Cell Solar Panels San Antonio - High Efficiency at Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 1000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

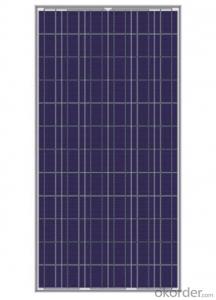

156*156mm Poly Cell Poly Panel China High Quality Module Price from China Factory

product description

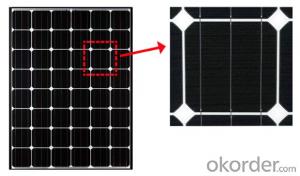

Multiple solar cells in an integrated group, all oriented in one plane, constitute a solar photovoltaic panel or solar photovoltaic module. Photovoltaic modules often have a sheet of glass on the sun-facing side, allowing light to pass while protecting the semiconductor wafers. Solar cells are usually connected in series in modules, creating an additive voltage. Connecting cells in parallel yields a higher current; however, problems such as shadow effects can shut down the weaker (less illuminated) parallel string (a number of series connected cells) causing substantial power loss and possible damage because of the reverse bias applied to the shadowed cells by their illuminated partners. Strings of series cells are usually handled independently and not connected in parallel, though (as of 2014) individual power boxes are often supplied for each module, and are connected in parallel. Although modules can be interconnected to create an array with the desired peak DC voltage and loading current capacity, using independent MPPTs (maximum power point trackers) is preferable. Otherwise, shunt diodes can reduce shadowing power loss in arrays with series/parallel connected cells.

product characteristic

1. High efficiency and High power.

2. Long-term electrical stability.

3. Lowest price and Fastest delivery.

4. Good quality and good service.

5.Bulk supply

6. Good Warranty

7.Big Sale

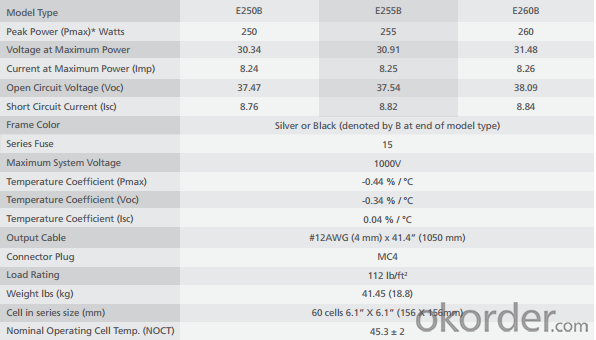

detail parameter

technological process

package&delivery

we pack goods with pallets and carton box

each one will be carefully examined by our staff.

- Q: Is it possible to store energy from solar panels for night?

- There okorder /

- Q: i dont wanna buy a solar panel becuase its too exspensive, i dont want use technical stuff i want to use every day materiels, but i need to know asap plzzzz.

- Make okorder

- Q: my dad met a guy representive for a solar panel company at a swapmeet Scam?

- Hard to say. Solar panels are becoming more common these days. May want to ask if the vendor is licensed and bonded contractor (if he's doing installation as well as panel sales). Find out the name of the equipment that this guy is selling (panels and other hardware) and do a search. For that matter, get the guys name and do a search on it to see he pops up elsewhere.

- Q: I'm part of the Sustainability group at school, the school principal is a d**k and doesn't care about the environment, he only cares about money.Me and the group will be talking in front of him and the school council (the people in-charge of the school's money) To convince them to put solar panels on the school roofs.I know that it definitely will help the school save on electricity bills, but it WILL cost a lot of money to put them in.In the end we just wanna reduce carbon emissions!HELP :)

- Show live examples such as those in Northern CA where the schools working with private industry funded a complete solar installation for a school district. Yes it can be done!

- Q: I been considering to get a solar panel system but I don't know if I'm going cut my electric bill every month , It's a lot of money to spend and I'm not really sure

- We okorder /

- Q: When people buy small solar panels, what are the steps to making it actually charge or run something.. I'm completely new to this of course and im curious. what kinda of wire and other devices are needed and how do you attach the wire and everything..

- Small solar panels produce almost no power that matters to anything. A whole square meter may produce 80 Watts when facing the noon sun in Arizona. take that down to 28 Watts in Erie Pa. The 80 Watts can charge a 2 volt battery at about 8 amps times 6 hours, or 48 Amp hours per day in Arizona or perhaps 5 amp hours/day in Erie. The amount of energy you can save declines as the battery is more charged so you need to use up the power stored before you have more to save. To do that charging you need a circuit that will carry 8 amps, including a voltage regulator. So, if your circuit can stand 20 amps the person in Arizona can run 2 square meters of panel. It may seem strange but the same is true for the person in Erie. The person in Erie has to allow for the maximum output of the panel, not the expected average. The person in Erie will occasionally have really clear skies and put out maximum rated amps. The amperage that the batteries can put out at maximum should not be used. That will destroy the battery. One puts a breaker on each output circuit to protect the circuit and a breaker that limits battery output to 20 amps based on a battery rated at 800 amps. That 800 amps is surge capacity. One or two panels does not really justify having this capacity for battery and circuitry. I can think of using it to provide an emergency LED lighting system.

- Q: Can solar panels be installed in areas prone to hurricanes or tornadoes?

- Yes, solar panels can be installed in areas prone to hurricanes or tornadoes. However, additional precautions and engineering considerations need to be taken to ensure their durability and resistance against strong winds and potential impact from debris. This can include using reinforced mounting systems, implementing proper anchoring techniques, and selecting panels that meet stringent wind load requirements.

- Q: Can solar panels be installed on a museum or cultural institution?

- Yes, solar panels can be installed on a museum or cultural institution. Many museums and cultural institutions have embraced solar energy as a sustainable and environmentally-friendly solution for their energy needs. Installing solar panels not only helps reduce their carbon footprint but also saves on electricity costs in the long run.

- Q: Can solar panels be used to power a museum?

- Yes, solar panels can certainly be used to power a museum. Solar panels are a reliable and sustainable source of energy that can generate electricity to meet the power requirements of a museum. By harnessing solar energy, museums can reduce their carbon footprint, lower energy costs, and promote environmental sustainability.

- Q: i need to know wat the parts of a solar panel are.

- Great answer Bill, I am just going to add aluminum frame and plastic clear cover on top of cells. The reason I am adding this is because after all this is installed then we have solar panel. Which as new looks and performs great but after a little while needs to be maintained. All factory warranties require solar panels maintenance to keep the warranty and optimum performance.

Send your message to us

125mm Mono Cell Solar Panels San Antonio - High Efficiency at Factory Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 1000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords