100% recycle cotton non woven fabric 70% recly cotton and 30% polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

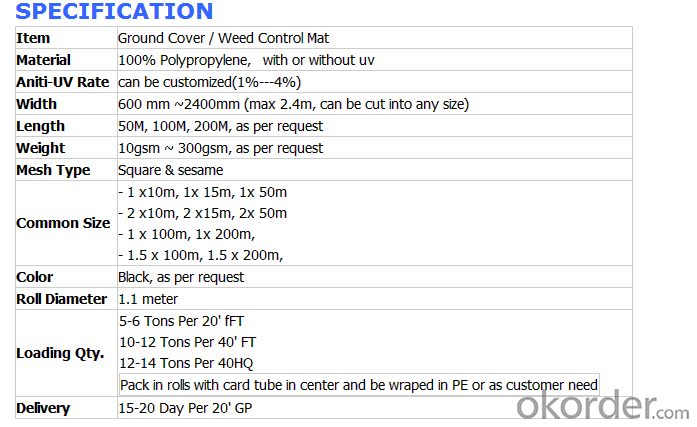

PP non woven weed control mat is made of environmentally friendly raw materials, pp spunbond nonwoven fabric. It used to prevent the growth of weed, without the use of potentially dangerous chemical sprays or labor intensive hoeing. Once installed, weed mat will continue providing protection for years without maintenance.

They are permeable fabrics, which allow air, water and nutrients to pass through, and designed to block out the sun to reduce photosynthesis and stop weed growth.

The use of landscaping fabrics has become extremely popular in recent years for many reasons:

1. Leisure time is maximised - the need for weeding and on-going maintenance is minimised

2. Environmentally friendly - no need for chemical based weed killers

3. Promotes healthier plants - it allows the soil to breath and water to permeate

We offer different types of weed control fabrics to suit all applications and budgets.

1. Available in a range of sizes & materials to suit various applications from small to large landscaping projects, in both commercial and domestic situations.

2. All our landscape fabrics are UV stabilised

3. Ideal for use under paths, patios, decking, paving, bark mulch, gravel etc.

FEATURES:

1. Weed suppressant and drainage control landscaping fabric

2. Spun bonded non-woven fabric – will not fray when cut

3. Easy to use

4. Environmentally friendly

5. Allows water, air and nutrients through, suppressing weeds without the use of chemicals

6. Good alternative to Plantex® where cost is a factor

7. UV Stabilised

8. Reduces the level of watering required due to the slower rate of water evaporation

FUNCTION:

1. Cover crops in the ground surface,prevent weeds and against the insect

2. Controlling soil humidity and the temperature

3. Does not affect the growth of the crops

4. Protects plants from harmfully solar radiation

5. Air permeability, water permeability help crops growth.

6. Mothproof, eco-friendly, breathable, anti-bacteria, tear-resistant, fusible

APPLICATIONS:

1. Weed block for landscaped garden beds

2. Permeable liners for planters (stops soil erosion)

3. Weed control under wooden decking

4. Geotextile for separating aggregate / soils under walkway blocks or bricks

5. Assists in preventing paving from settling unevenly

6. Landscape fabric prevents soil erosion

Health - Hygiene & Medical

Shoes & Garments

Coveralls

Pillow cases

Airline Headrests

Interlinings

Clothing and Glove insulation

Bra and Shoulder Padding

ADVANTAGES:

1. Lower labour costs as no weeding maintenance for years;

2. Water seeps through and can conserve soil moisture for improved growing conditions;

3. Air escapes – humidity rises through the mat for a more controlled growing environment;

4. Increase crop yields close to 25% due to improved growing conditions and absence of water stress and competition of nutrients absorption from weeds;

5. Minimises bacteria and fungus problems especially Algae;

6. Strong, woven construction or pressed fibre sheet resists tears and punctures;

7. Resistant to mildew, rot, water, sunlight and most of the agricultural chemicals

8. Fertilizer is applied on the mat, thus helping the owner or estate manager to monitor the progress of manuring;

9. Prevents soil erosion or leaching of soil nutrients or fertilizers applied;

10. Environmental friendly.

FAQ:

Q .What is the material of the non woven fabric ?

A .PP spunbond non woven fabric

Grade A: 100% Polypropylene

Grade B: 90% Polypropylene +10% filling

Q .What about the width of the non woven fabric ?

A .We can cut the fabric as your requirement. Our width of machine is 240cm, so the max of the width is 240cm

Q .What about the color ?

A .Any color is available. You just need to give me the Panton Num or send me your sample. Then we will make the color samples to you for approve

Q .What about the GSM ?

A .The thinnest of the fabric that we can produce is 9g, and the thickest is 250g. Normally the fabric that used in bag making is 50-100g, the agricultural used is 17-50g, the home used fabric is 40g and so on...

Q .What about the delivery time ?

A .We can finish the production in 2-3 days (40ft HQ)

Q .What about the price ?

A .We are the factory of the PP nonwoven fabric, We can supply you with good quality and favorable price

- Q: Textile fabric classification, dyeing and finishing processing is what?

- New type of fabric in the chenille fabric, knitted bamboo fabric should also be classified.

- Q: What are the types of textiles that are different?

- According to the different production methods are divided into line class, with class, rope, woven fabrics, textile fabrics and other six categories:

- Q: Performance requirements for textile fibers

- The abrasion resistance of the fiber is closely related to the fastness of its textile products. The wear and tear of the pros and cons is the performance of clothing with fabric is an important indicator.

- Q: What are the Advantages and Disadvantages of PE and PVC in Textile Fabrics

- pvc material rain better than the point, PVC resistance than PE slightly better, but

- Q: The difference between double distribution and processing in textile fabrics

- Double distribution - that is, fabric fabric is where you specify, they buy, processing, and then sold to you.

- Q: What is the earliest textile tool?

- Spring and Autumn Warring States period has a greater improvement and development of looms. Jiangsu Sihong Cao Zhuang unearthed Han stone carved with "mother coffin diagram", the figure has oblique loom type. "Zhu Jing, carts" cloud "car carts, shaft of its empty" Zhu Xi "The Book of Songs" explained that "loom, weft wearers also, the axis of the people also" loops that shuttle, the axis is the main line axis

- Q: Do you need to do environmental protection for dry textile processing?

- Individual industrial and commercial business license is only one, but the composition is divided into two types of family management and personal business

- Q: From the yarn to the finished textile fabric production process is how

- Is the famous American chemist Carothers and his research team invented. The main varieties of nylon are nylon 6 and nylon 66, accounting for the absolute dominant, followed by nylon 11, nylon 12, nylon 610, nylon 612, in addition to nylon 1010, nylon 46, nylon 7, nylon 9, nylon 13, Varieties are nylon 6I, nylon 9T and special nylon MXD6 (barrier resin) and so on

- Q: Analysis of import and export of textile

- From 2011 to 2013, the main business income of textile enterprises above designated size increased by 12% on average, down 6.8 percentage points over the previous decade; the total assets increased by 9% annually, down by 3.1 percentage points over the previous decade

- Q: "Textile color standard system"

- Color fastness and poor, directly related to the health and safety of the human body, poor color fastness in the process of wearing, run into the rain, sweat will cause the fabric off the paint off,

Send your message to us

100% recycle cotton non woven fabric 70% recly cotton and 30% polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords