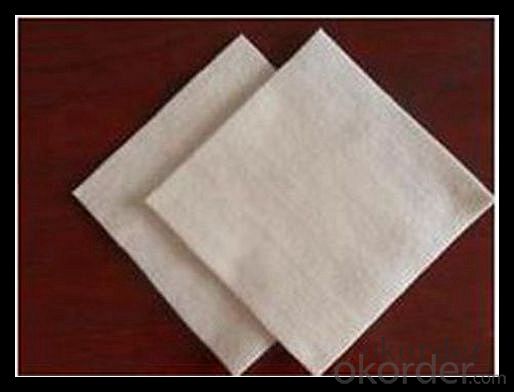

100% Polyester Filament Woven Geotextile Fabric Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

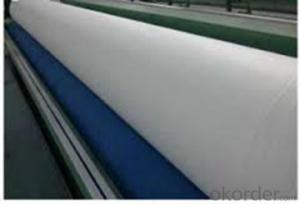

Geotextile Specifications

1) Weight / Mass: 100g/m2-1500g/m2

2) Width: Within 8 m (1m-8m)

3) Length: 50m-100m/roll (as request)

4) Material: PP / PET

Features and Benefits

Geotextiles are made from either polypropylene or polyester and geotextile fabrics come in three basic forms: woven, needle punched (resembling felt), or heat bonded (resembling ironed felt). In Australia the most popular geotextile used is the polyester needle punched fabric, as the polyester is more UV stable than the polypropylene material.

Our Service

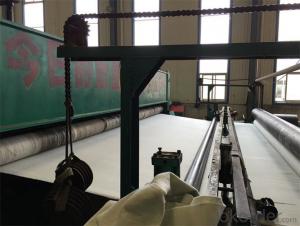

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the key differences between woven and nonwoven geotextiles?

- Woven geotextiles are made by weaving individual threads together to create a strong and durable fabric, while nonwoven geotextiles are made by bonding fibers together using heat, chemicals, or mechanical processes. Woven geotextiles have high tensile strength and are commonly used for soil stabilization, erosion control, and separation of different soil layers. On the other hand, nonwoven geotextiles have excellent filtration and drainage properties, making them suitable for applications such as filtration, separation, and protection. Overall, the key differences between woven and nonwoven geotextiles lie in their manufacturing process, physical properties, and intended usage.

- Q: Are geotextiles suitable for use in erosion control socks?

- Yes, geotextiles are suitable for use in erosion control socks. They are specifically designed to prevent soil erosion by providing a protective barrier and promoting water infiltration. Geotextile erosion control socks effectively control sediment runoff and stabilize slopes, making them an ideal choice for erosion control projects.

- Q: Geomembrane and geotextile difference?

- Geotextile is woven up the "cloth", geomembrane is based on the geotextile paste a layer of impermeable membrane.

- Q: Are geotextiles resistant to biological clogging?

- Yes, geotextiles are generally resistant to biological clogging. They are designed to allow water to pass through while preventing the movement of soil particles. This characteristic helps to minimize the growth of organisms, such as bacteria and algae, that can cause clogging. However, it's important to note that the level of resistance may vary depending on the specific type and quality of geotextile used.

- Q: Can geotextiles be used for drainage?

- Yes, geotextiles can be used for drainage. They are commonly used in various drainage applications such as road construction, retaining walls, and landfills. Geotextiles help to enhance the drainage system by allowing water to pass through while preventing the loss of soil particles. They also provide filtration and separation, ensuring optimal drainage performance.

- Q: Can geotextiles be trampled on the ground?

- Trampled on a long time to step on the geotextile will have an impact, geotextile main function is anti-penetration

- Q: How do geotextiles help with soil separation in railway ballast systems?

- Geotextiles help with soil separation in railway ballast systems by acting as a barrier between the ballast and underlying soil. They prevent the mixing of fine soil particles with the ballast, which can lead to settlement and track instability. The geotextiles allow for proper drainage and filtration of water, while ensuring the stability and longevity of the railway tracks.

- Q: Why do you want to add 1 to the amount of geotextile

- There are overlapping area and loss, I am specializing in the production of geotextiles

- Q: How do geotextiles contribute to land reclamation projects?

- Geotextiles contribute to land reclamation projects by providing erosion control, soil stabilization, and drainage solutions. They act as a barrier between the underlying soil and overlying materials, preventing soil erosion caused by wind or water. Geotextiles also help stabilize the soil, allowing vegetation to grow and preventing the formation of unstable slopes or embankments. Additionally, they aid in efficient drainage, ensuring proper water flow and preventing waterlogged conditions that could hinder the reclamation process. Overall, geotextiles play a crucial role in land reclamation projects by enhancing the stability and productivity of reclaimed land.

- Q: What are the considerations for geotextile selection in coastal engineering projects?

- When selecting geotextiles for coastal engineering projects, several factors should be considered. These include the intended application, site conditions, longevity requirements, and environmental considerations. The geotextile's strength, permeability, and durability must align with the project's specific needs to effectively control erosion, stabilize sediment, or protect against wave action. Additionally, factors such as UV resistance, resistance to biological degradation, and compatibility with other materials used in the project should be evaluated to ensure long-term success and minimize negative impacts on the coastal ecosystem.

Send your message to us

100% Polyester Filament Woven Geotextile Fabric Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords