10.75in TitanShield Casing, 13.84mm WT

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

9.625" CO₂ Injection Casing

CCUS Specialist: Handles 10,000ppm CO₂ environments

Tech Edge:

Internal Cladding: 1.0mm Inconel 625 layer

pH Resistance: 3.5-11.0

Expansion Joints: Accommodate 1.2% volume changes

Real-World Use:

At Norway's Sleipner CCS project, these casings maintained integrity through 50+ injection cycles over 8 years.

Key Specs:

Max OD: 244.5mm (9.625")

Pressure: 6,000psi working pressure

Coupling: Tapered trapezoidal thread

Offer: Free CO₂ corrosion calculator + 15-year performance guarantee

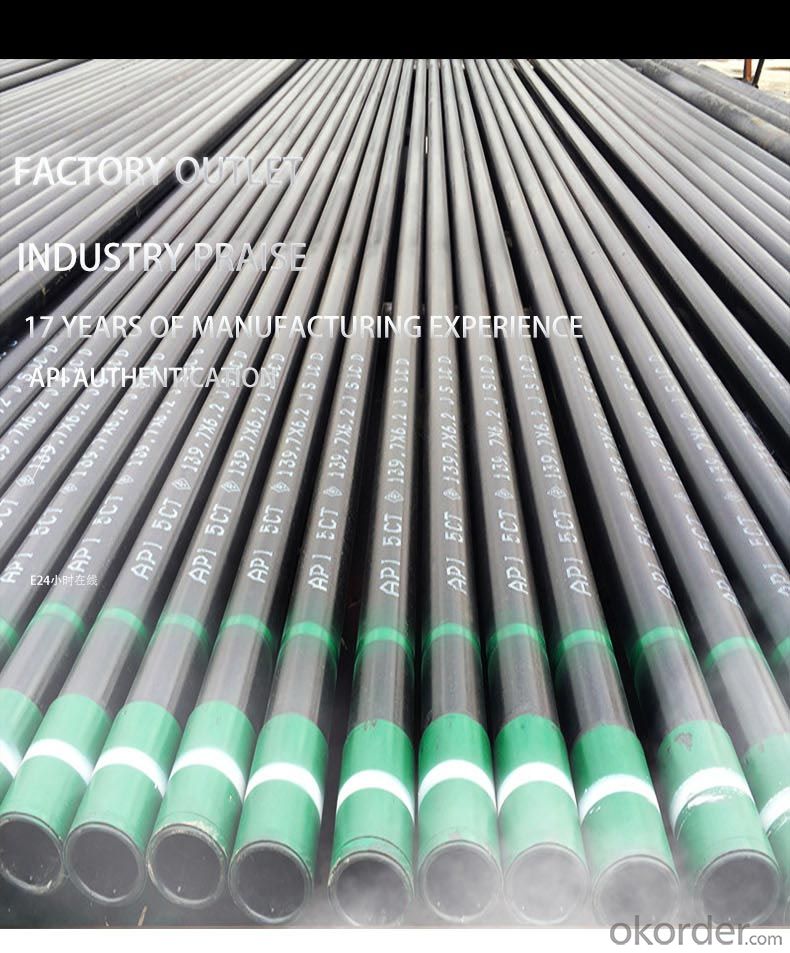

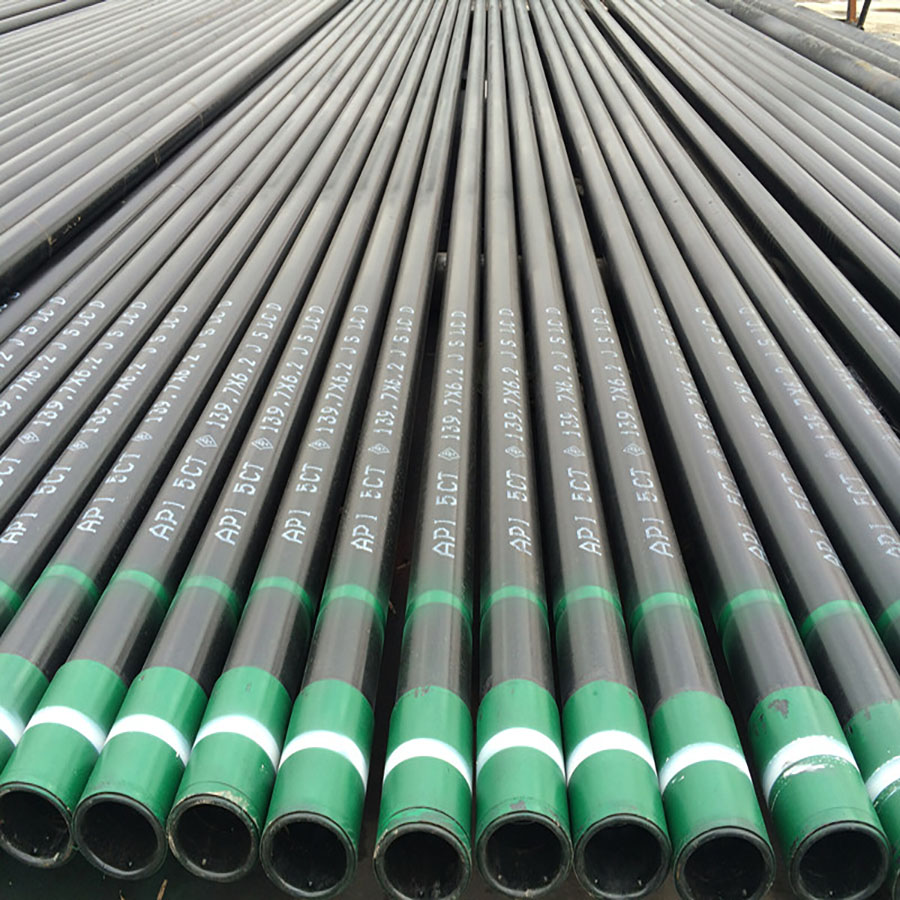

Petroleum Casing Product Information

1. Product Overview

J55 Steel Deep Well Casing, P110 High-Grade Drilling Casing

petroleum casing is strictly manufactured in compliance with API 5CT standards, covering mainstream steel grades such as J55, N80, and P110. It is suitable for wellbore reinforcement and formation isolation in onshore oilfields, offshore platforms, and complex geological environments, ensuring lifecycle safety of oil and gas wells.

2. Technical Specifications

Size Range:

Outer diameter 114.3 mm (4.5") to 508 mm (20"), wall thickness 6.2-25.4 mm, tolerances conform to API 5CT standards (outer diameter ±0.5%, wall thickness ±10%).Mechanical Properties:

J55 Grade: Yield strength ≥379 MPa, tensile strength ≥517 MPa;

P110 Grade: Yield strength ≥758 MPa, tensile strength ≥965 MPa;

Collapse resistance: N80 Grade ≥80 MPa, P110 Grade ≥138 MPa (tested per ASTM A370).

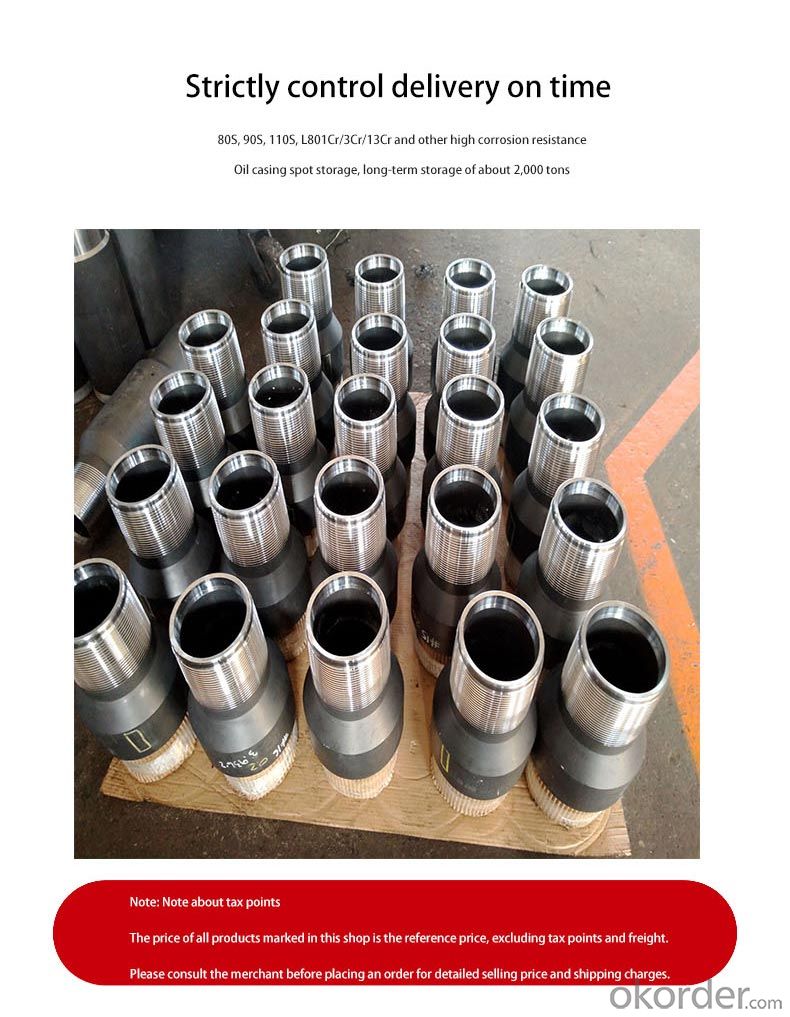

Thread Performance:

API round thread (BTC) sealing pressure ≥20 MPa;

Premium connections (e.g., BGT2) helium leakage rate ≤1×10⁻⁶ cm³/s (tested per ISO 13679 CAL IV).

3. Chemical Composition (Example: L80 Grade)

| Content | 0.25% | 1.20% | 0.45% | 0.50% | 0.25% | 0.020% | 0.010% |

| Note: Cr-Mo alloy design enhances H₂S corrosion resistance (H₂S partial pressure ≤0.3 kPa). |

4. Application Scenarios

High-Temperature & High-Pressure Wells:

L80-13Cr material withstands 180°C and CO₂ partial pressure ≤1 MPa (per NORSOK M-001).Shale Gas Horizontal Wells:

TP140TT high-collapse casing with internal pressure resistance ≥105 MPa, compatible with multi-stage fracturing.Deepwater Offshore Wells:

9-5/8" casing passes 30 MPa external pressure test, suitable for 3,000-meter water depth.

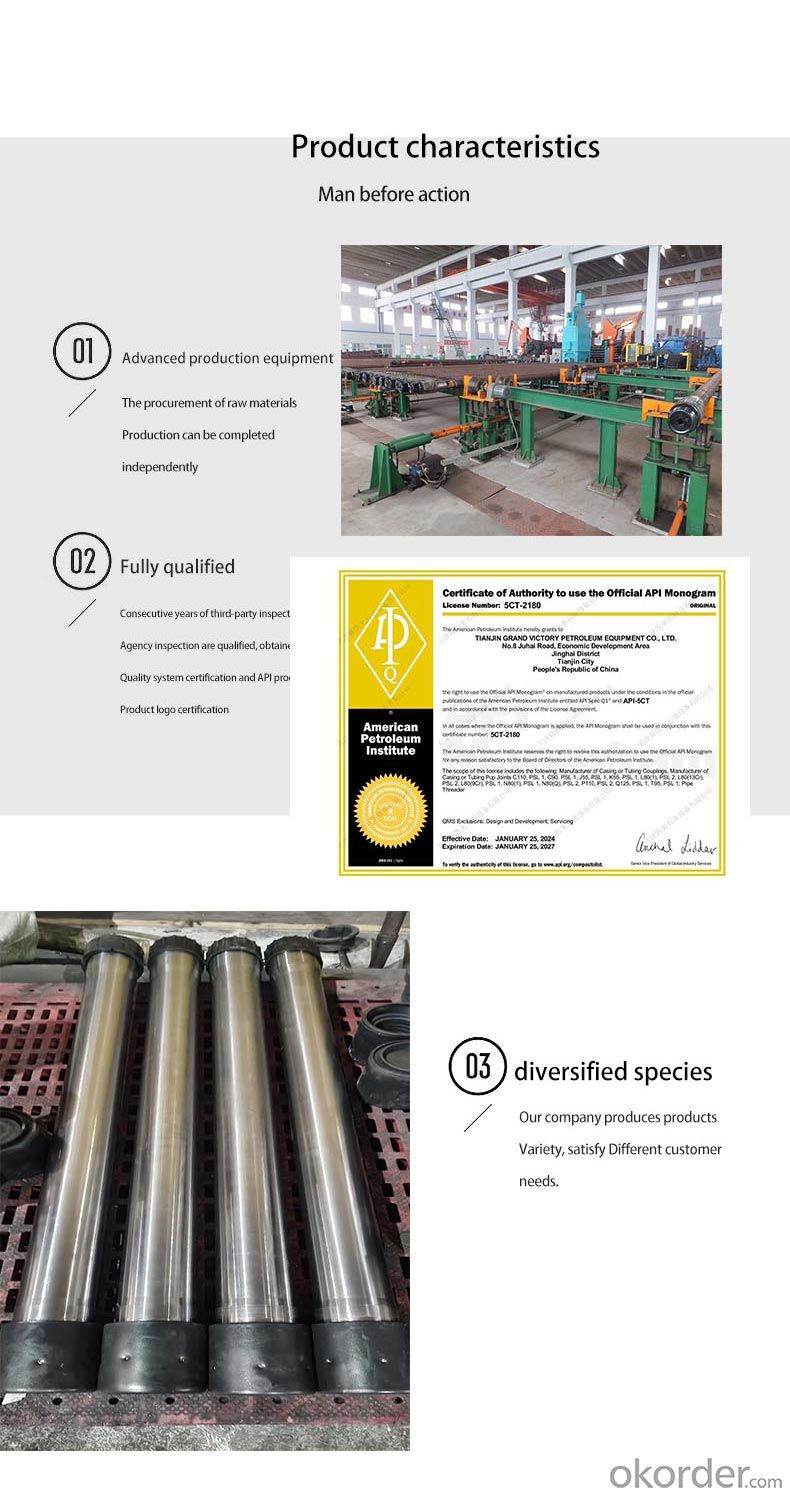

5. Production Process

Material Smelting:

Electric Arc Furnace (EAF) + LF refining, sulfur/phosphorus ≤0.015%;

Continuous casting billet Φ180-400 mm, central segregation ≤Class C 1.0.Hot Rolling:

Three-roll retained mandrel mill, wall thickness uniformity ≤5%;

Online spray cooling, final rolling temperature 900±20°C.Heat Treatment:

Quenching (920°C water cooling) + Tempering (620°C air cooling), hardness 22-32 HRC;

Sour-service pipes use HWQ process, grain size ≥ASTM 7.Quality Inspection:

100% ultrasonic testing (UT) for longitudinal defects (sensitivity Φ1.6 mm flat-bottom hole);

Full-length hydrostatic test (50-100 MPa, holding ≥10 seconds);

Drift test with API drift mandrel (100% pass rate).

- Q: What is hot rolled steel pipe? What is a cold drawn steel tube?

- Overview of two processesHot-rolled (extrusion seamless pipe): billet, heating, perforation, three roll cross rolling, rolling or extrusion, tube to tube diameter (or reducing) - cooling - tube, straightening, pressure test (or testing), marking and warehousing.Cold drawing (rolling) seamless steel pipe: round tube to heating to perforation, annealing, pickling, leading to oil (copper), multi pass drawing (Leng Zha), the blank pipe, heat treatment, straightening, pressure test (testing), marking and warehousing.

- Q: What are the common protective coatings used on the inner surface of steel pipes?

- The common protective coatings used on the inner surface of steel pipes include epoxy, polyurethane, and cement mortar coatings. These coatings provide corrosion resistance, prevent the formation of scales, and improve the durability and lifespan of the pipes.

- Q: Can steel pipes be used for the construction of transmission towers?

- Yes, steel pipes can be used for the construction of transmission towers. Steel pipes are known for their strength, durability, and ability to withstand heavy loads and harsh weather conditions, making them an ideal choice for building transmission towers. Steel pipes can provide the necessary support and stability required for high-voltage power transmission lines.

- Q: What is the difference between steel pipes and concrete pipes?

- Steel pipes and concrete pipes differ in terms of their material composition and physical characteristics. Steel pipes are made from steel alloys, which make them strong, durable, and resistant to corrosion. They have high tensile strength, allowing them to withstand high-pressure applications. Steel pipes are commonly used in industries such as oil and gas, plumbing, and construction. On the other hand, concrete pipes are made from a mixture of cement, aggregates, and water. They are known for their exceptional compressive strength and durability. Concrete pipes are commonly used in sewage systems, drainage systems, and culverts. In terms of installation, steel pipes are lightweight and easy to handle, making them more convenient to transport and install. Concrete pipes, on the other hand, are heavier and require specialized equipment for installation. Additionally, steel pipes have a smooth internal surface, which allows for efficient flow of fluids or gases. Concrete pipes, however, have a rougher internal surface, which may cause more friction and result in reduced flow rates. Overall, the choice between steel pipes and concrete pipes depends on the specific requirements of the project, including factors such as application, budget, and durability needs.

- Q: What quota should be installed for heating seamless steel pipe?

- Seamless steel pipe having a hollow cross section, used as a conduit for conveying fluids, such as pipelines for transporting petroleum, natural gas, gas, water, and certain solid materials.

- Q: What is the bending strength of steel pipes?

- Steel pipes have the ability to withstand bending forces without breaking or permanently deforming, which is known as their bending strength. This strength can vary depending on factors like the type of steel, the grade of steel, the diameter and thickness of the pipe, and the manufacturing process. Steel pipes are highly durable and strong, making them suitable for many different uses. The bending strength of steel pipes is typically measured by the maximum bending moment or stress that the pipe can handle without failing. Engineers and manufacturers determine the bending strength of steel pipes using various testing methods, such as three-point or four-point bending tests. These tests involve applying a known force or moment to the pipe and measuring its deflection or stress response. The bending strength of steel pipes can also be affected by mechanical properties like yield strength, tensile strength, and elongation. These properties determine the overall strength and ductility of the steel, which are crucial for its bending strength. It's important to note that the bending strength can vary depending on the specific application and the load conditions. For instance, pipes used in structural or load-bearing applications may require higher bending strength than pipes used for plumbing or conveyance purposes. In conclusion, the bending strength of steel pipes is determined by factors such as the type of steel, the grade of steel, the diameter and thickness of the pipe, and the manufacturing process. Testing methods and mechanical properties are used to assess the bending strength of steel pipes, ensuring they are suitable for different uses and load conditions.

- Q: What is the difference between schedule 10 and schedule 40 steel pipes?

- Schedule 10 and schedule 40 steel pipes find common usage in various industries for different purposes, differing in their wall thickness and pressure ratings. When it comes to wall thickness, schedule 10 pipes possess a slimmer wall in comparison to schedule 40 pipes. This attribute results in schedule 10 pipes having a smaller internal diameter and the ability to withstand lower pressure compared to schedule 40 pipes. While schedule 10 pipes typically have a wall thickness of 0.109 inches, schedule 40 pipes boast a wall thickness of 0.154 inches. The thinner walls of schedule 10 pipes make them ideal for applications with low pressure, such as domestic water supply, drainage systems, and general plumbing. Additionally, they are frequently employed in lightweight structures or where weight is a significant concern. On the other hand, schedule 40 pipes are specifically designed to handle higher pressure and are commonly utilized in industrial settings. These pipes are often found in applications such as oil and gas pipelines, chemical processing plants, and high-pressure fluid systems. The thicker walls of schedule 40 pipes provide them with enhanced strength and durability, enabling them to withstand higher pressure and stress. To summarize, the primary distinction between schedule 10 and schedule 40 steel pipes lies in their wall thickness and pressure ratings. Schedule 10 pipes have a thinner wall and are suitable for low-pressure applications, while schedule 40 pipes possess a thicker wall and can withstand higher pressure. It is crucial to select the appropriate schedule based on the specific requirements and pressure limitations of the intended application.

- Q: How are steel pipes classified based on their thickness?

- Steel pipes can be classified based on their thickness into three main categories: Schedule, Nominal Pipe Size (NPS), and Wall Thickness. The Schedule classification is commonly used in North America and refers to the wall thickness of the pipe. It is denoted by numbers such as Schedule 10, Schedule 40, and Schedule 80, where the higher the number, the thicker the pipe. The Nominal Pipe Size (NPS) classification, on the other hand, is used internationally and refers to the inside diameter of the pipe. It is expressed in inches and is usually followed by a schedule number to indicate the wall thickness. For instance, NPS 6 Schedule 40 means a pipe with a 6-inch inside diameter and a wall thickness according to Schedule 40. Lastly, steel pipes can also be classified based on their wall thickness in millimeters or inches. This classification provides a more precise measurement of the pipe's thickness, usually referred to as the "wall thickness" or "wt" in specifications. The wall thickness is measured from the outside diameter to the inside diameter and can be expressed in various units of measurement, such as millimeters, inches, or gauge. In conclusion, steel pipes are classified based on their thickness using different systems such as Schedule, Nominal Pipe Size (NPS), and Wall Thickness. These classifications help ensure that the appropriate pipe is selected for specific applications, considering factors such as pressure requirements, structural integrity, and compatibility with other components of the system.

- Q: Are steel pipes resistant to UV degradation?

- Steel pipes are generally not resistant to UV degradation. Exposure to ultraviolet (UV) radiation over time can cause steel pipes to undergo various forms of degradation. UV radiation can cause the steel to become brittle, leading to cracking and potential failure. Additionally, UV radiation can also cause corrosion and discoloration on the surface of the steel pipes. To mitigate the effects of UV degradation, protective coatings or paint can be applied to the steel pipes to provide a barrier against UV radiation. Regular maintenance and inspections are also necessary to identify any signs of UV degradation and take appropriate measures to prevent further deterioration.

- Q: Are steel pipes suitable for transporting chemicals?

- Yes, steel pipes are suitable for transporting chemicals. Steel pipes have excellent strength and durability, making them capable of handling various corrosive chemicals and maintaining their structural integrity. Additionally, steel pipes can withstand high pressure and temperature, making them a reliable choice for chemical transportation.

Send your message to us

10.75in TitanShield Casing, 13.84mm WT

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Related keywords