1. Description of Craft Paper Laminated Packing Bag with Tear Notch for Packing:

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

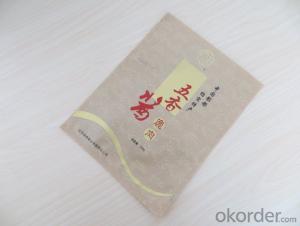

1. Description of Craft Paper Laminated Packing Bag with Tear Norch for Packing:

Craft Paper Laminated Packing Bag with Tear Norch for Packing are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Craft Paper Laminated Packing Bag with Tear Norch for Packing mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Craft Paper Laminated Packing Bag with Tear Norch for Packing:

Excellent quality control

Experienced facotry produced

SGS passed

3. Craft Paper Laminated Packing Bag with Tear Norch for Packing Photos:

4. Craft Paper Laminated Packing Bag with Tear Norch for Packing Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Craft Paper Laminated Packing Bag with Tear Norch for Packing:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: What are the requirements of the mark on the cement packing bag?

- Label on cement packing bagCommon C25, C30, C35, C40 label is the cement packaging machine packaging cement mark, specific what label, drawings will generally indicate, general use C25 on the line, the greater the strength higher.

- Q: What are the advantages and disadvantages of OPP and CPP membranes? What kind of bags are they used for?

- (feature film, also called special film) potential uses include: food packaging, candy packaging (twisted film), drug packaging (infusion bag), on the album, folders and files and other fields instead of PVC, synthetic paper, adhesive tape, name card holder, ring folder and composite bag stand.

- Q: The vacuum packing bag is sealed. How can I open the zipper?

- In addition to wax, you can also use lubricating oil, to pick a relatively transparent, clean kind of, in the zipper ring drop a few drops, repeated several times, can also achieve smooth purposes.

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!

- Q: What's the packing of the air in the food package?

- For example, our common bag of potato chips, which is mostly nitrogen N2, a gas filling packaging is fat, on the one hand is the replacement of the original air bag and prolong the shelf life; on the one hand, there is a large amount of gas support chips during transportation and storage, can also be to reduce the impact of fragmentation. You certainly don't want to buy potato chips all over it.

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- Aluminum filmThe first consideration of food packaging is the barrier properties of packaging materialsBecause barrier property is good, the preservation time is long, the shelf life is long, the quality can guarantee betterAt present, all food packaging materials, aluminum foil barrier is the best (followed by some high polymer plastics, like EVOH, PVDC, etc.)Therefore, the most common, always in the middle of two layers of plastic film, a layer of aluminum foil, to improve barrier,But why not use aluminum foil packaging alone, but also two or more layers of plastic film?,

- Q: Is there any identification on the vacuum package?

- Continue ink jet printer (continuous spraying machine), referred to as CIJ inkjet printer. The principle of operation is that the ink is ejected continuously through a single nozzle and is broken by crystal oscillation to form ink dots. After the ink point is charged and deflected at high pressure, the ink is scanned on the surface of the moving object. Such as Domino A100.

- Q: What does "13 silk" in vacuum packing bag mean?

- The vacuum packing bag 13 silk refers to the vacuum packing bag's thickness is 0.13 millimeters.

- Q: What material should be used for transparent packing bags? How many cents do you want?

- PVC products for packaging containers, mainly for a variety of film and film. PVC containers mainly produce mineral water, drinks and cosmetics bottles, as well as packaging for refined oils. The PVC film can be used in CO extrusion with other polymers to produce low cost laminates and transparent articles with good barrier properties. PVC film can also be used for stretch or heat shrink packaging, used for packaging mattresses, cloth, toys and industrial goods.

- Q: What are the types of composite packaging bags?

- Folding small packing bag (or ordinary packing bag)A bag of less weight, usually made of single or double layers. For some special packing bags, it can also be made of multi layers and different materials: the packing range is wide, and the packing can be used in liquid, powder, lump and irregular shape.In these packing bags, the packing bags are suitable for transportation and packing, and the general transport packing bags are suitable for external packing and transportation packing. Small package bags are suitable for inner packing, packing and commercial packing.

Send your message to us

1. Description of Craft Paper Laminated Packing Bag with Tear Notch for Packing:

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords