1/4 Inch Plywood Engineered Wood Veneer EV Wood Veneer 1250x2700mm for Door

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Engineered Veneer Wood:

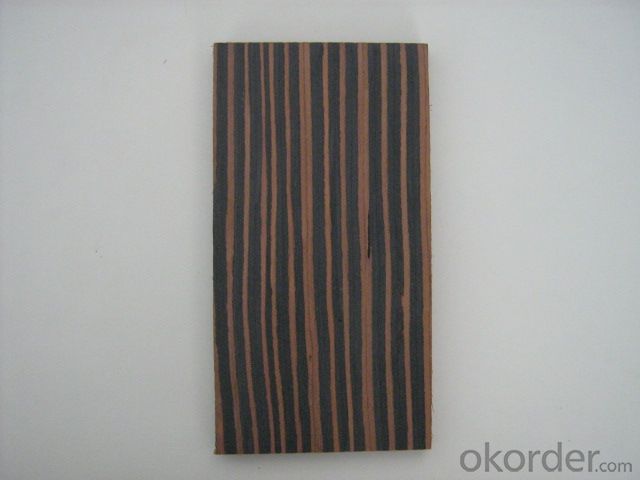

Engineered Veneer Unreal Color Wood for Door Skins and Plywood

1.Thickness:0.3mm-0.6mm

2.Grade:furniture,door and panel grade

Specification of Engineered Veneer Wood:

(1)Regular Size: Width640mm*Thickness 0.30-0.6mm *Length 2500mm

(2)Application: Can be used in interior decoration,furniture and music equipments , plywood or MDF , door etc

(3)MOQ: 500m2

(4)Packing:Wood pallet covered with plastic and fixed by iron belt

(5)Terms of payment: TT, LC at sight

(6)Delivery date:within 7—10 days after order confirmed. Your special order is also welcome

Other Information of Engineered Veneer Wood:

Dimension | 2 x 8 feet/2.5mx64cm

| |

Thickness | 0.5mm/0.3mm | |

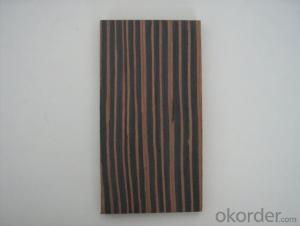

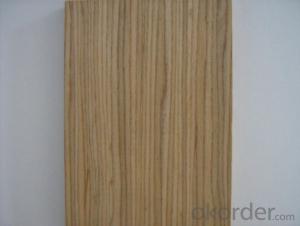

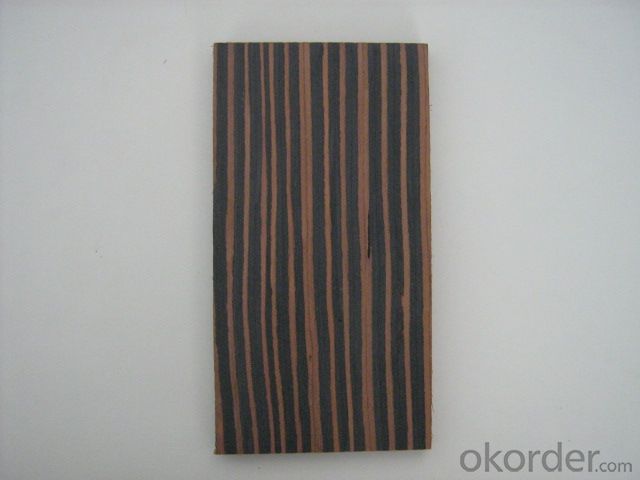

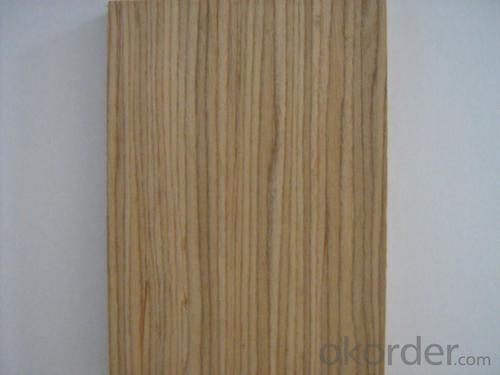

Grain | quarter cut/crown cut | |

Grade | Good quality | |

Moisture | To be 8%-10% at time of shipment. | |

Quality | Clear grain, uniformity color, no chew silk, no any defect | |

Usage | High grade Furniture, Restaurant and hotel decoration. Decoration board. Be pasted on MDF, Plywood. Other wood product, ect. | |

Package | Wooden pallet packing | |

Quanity fits in container | 20’GP | 35000m2 |

40’GP | 65000m2 | |

40’HQ | 75000m2 | |

MOQ | No requirements or can place a sample order to test our quality. | |

Delivery time | 5-15 days on receipt of deposit. | |

Price terms | EXW, FOB, CIF, CNF. | |

Payment terms | By T/T, 30% for depoait and 70% is paid before shipment or after goods' inspection | |

Process of Engineered Veneer Wood:

Log Selection

EV is generally produced from Chinese Poplar logs, grown locally either by local co-operatives,

or in registered plantation areas. The light natural colour and soft grain definition of Poplar makes it wellsuited to the production of EV. The process of converting timber into EV starts with the selection of logs, following which they are bought to the mill for processing. The timber is trimmed, sawn to length and debarked. The logs are now ready to be peeled.

Peeling of the Logs

The logs are mounted onto a giant lathe. Within minutes the logs are peeled into rotary veneers. This is achieved by pressing a rotating log towards a large blade, thinly peeling a continuous sheet of veneer off the log. The veneer is dried, stacked and then graded. It is now ready to be dyed.

Drying

EV veneers can be dryed to a consistent colour to suit the market requirement. The raw veneer leaves are stacked into a stainless steel cage. Once completely loaded, the stainless steel cage is immersed into a pressurized, heated vat that is filled with water soluble dry. This system ensures that each leaf is given the correct amount of time to allow the dry to completely penetrate each individual leaf of veneer. Once the desired colour has been achieved, the leaves are unloaded from the vat, dried and given a final inspection before going to the gluing stage.

Gluing

The gluing process is critical for the performance of the finished product. A layer of glue goes between each leaf of veneer, to bond the leave of veneer together. Once the stack has been laid up it is then put into a high pressure press to bond the leaves together, creating a large rectangular block.

Slicing of the Block

The block in now ready to be sliced into veneer leaves. Once the block has been produced, it is turned through 90 degrees, to present the end grain, then mounted to the slicing unit. The blade now runs across the end grain of the block, slicing thickness controlled leaves of veneer. The veneer leaves that are produced are approximately 0.4mm thick, and in 2440 x 1220 format. The veneer is now ready to be used as face veneer for Eucalyptus and Poplar core plywood products.

Packing of Engineered Veneer Wood:

- Q: Class I resistant weather plywood Class II water resistant plywood

- slab molding (mixing resin and additives pavement), under hot pressure, so that cellulose and Hemicellulose and lignin plasticized to form a plate.

- Q: What types of plywood can be divided into?

- It can withstand cold water or short-term hot water immersion, but not resistant to boiling.

- Q: What is the type of plywood editing?

- decorative plywood (for construction, furniture, vehicles and ship decoration materials), the general use of plywood (for packaging, bedding and other uses)

- Q: What are the defects in plywood material?

- Fracture split, end split The fiber is separated in the direction of the grain, usually starting from one end and extending through the thickness of the morning plate

- Q: The density of the plywood is greater than that of the same kind of wood

- The greater the unit pressure when gluing, the greater the density of the plywood. As the wood at high temperature easy to produce plastic deformation, hot glue gluing than the compression of the compression rate is greater.

- Q: What is the amount of construction works used for this plywood?

- Three types of plywood for moisture-resistant plywood, can be immersed in cold water for a short time, suitable for indoor use at room temperature. For furniture and general construction purposes;

- Q: What are the advantages and disadvantages of plywood?

- the construction is convenient, not Qu Qiao, stripes tensile mechanical properties. light weight, clear lines, insulation, strength, not easy to deformation.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- Mild wood veneer: with Ash, willow wood, color wood, birch and other peeling into 0.1-0.5mm thick sheet, plywood as a substrate made of glued, its beautiful pattern, good decorative

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: What are the shortcomings of plywood

- the plywood is not as smooth as the density of the board, with the plywood to do the grassroots, the surface and then bonding fire board, aluminum panels and other decorative panels, as the density board to do solid base

Send your message to us

1/4 Inch Plywood Engineered Wood Veneer EV Wood Veneer 1250x2700mm for Door

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords