026 Aluminum Coil Hot Rolled Aluminium Circle AA3003 H14

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

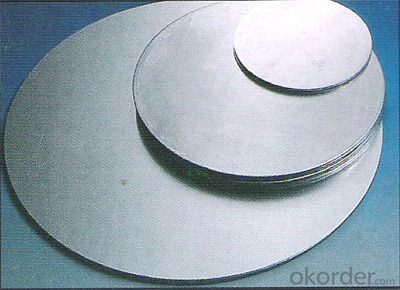

Hot Rolled Aluminium Circle is widly used in cooking pot field. There are two kinds of production method. One is hot rolled aluminium circle, the other is continuous casting aluminium circle. The mechanical for the two circle is different. If you will deep push, we recommend Hot rolled aluminium circle. If you just spinning, we recommend continuous casting aluminium circle.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diemeter | Package |

| AA3003 | H14 | 0.2MM-3MM | 90MM-1200MM | Exportation Pallet |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: hello, i have been recently studying the production of aluminum from aluminum dross (recycling of aluminum) .this chemical equations represents the hydrolization of sodium aluminate to obtain aluminum hydroxide :Na2Al2O4 + 4H2O -----------gt; 2Al(OH)3 + 2NaOHafter that the next step is to produce Al2O3the next step to obtain Aluminum is to pass a current through the solution (electrolysis)this is the part that i don't get .... how could we electrolyze Aluminium oxide to produce aluminum if we are recycling aluminum ... i mean electrolysis consumes most of the energy and is very expensive .... so how do electrolysis be used in the recycling industry...please answer ... all answers are really appreciated ....and correct me if my informations are wrong...

- OMG Zilla...you're a TC!!! i might somewhat not think of roughly God or the rest seeing via aluminum foil. It makes me experience bare. I positioned on it each and every of the time. undergo thinks that's attractive. :)

- Q: Can aluminum coils be used in building facades?

- Yes, aluminum coils can be used in building facades. Aluminum is a popular material choice for building facades due to its numerous benefits. It is lightweight, durable, and corrosion-resistant, making it suitable for exterior applications. Aluminum coils can be formed into various shapes and sizes, allowing for creative and versatile design possibilities. Additionally, aluminum is available in a wide range of finishes, including anodized, painted, and coated, providing further customization options for building facades. Moreover, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for construction projects. Overall, aluminum coils are a viable option for building facades, providing both aesthetic appeal and functional performance.

- Q: aluminum foil production of ERP software, requiring a comprehensive production process, and have special assistance to pre operation, the best price is reasonable

- Aluminum foil and aluminum coil production is a typical manufacturing type. With ERP, you can manage all the production processes, carry out cost accounting and voucher making, and can download the long-term trial.

- Q: How do aluminum coils contribute to the corrosion resistance of products?

- There are several ways in which aluminum coils contribute to the corrosion resistance of products. Firstly, aluminum itself is highly resistant to corrosion, thanks to the formation of a natural oxide layer when exposed to oxygen. This layer acts as a protective barrier, preventing further oxidation and corrosion. When aluminum is shaped into coils, it offers additional benefits for corrosion resistance. The coil form allows for a more even distribution of the material, ensuring that the entire surface area of the product is covered by the protective oxide layer. This helps to prevent localized corrosion and ensures a consistent level of corrosion resistance throughout the product. Furthermore, aluminum coils can be coated with various protective coatings or treatments to enhance their corrosion resistance even further. These coatings provide an extra layer of protection against environmental factors like moisture, chemicals, and UV radiation, which can speed up corrosion. Additionally, aluminum coils are often used in conjunction with other materials, such as galvanized steel or stainless steel, in products. These combinations, known as bimetallic or trimetallic products, utilize the different properties of each material to enhance corrosion resistance. For example, the aluminum layer can act as a sacrificial anode, corroding preferentially to protect the underlying material from corrosion. To summarize, aluminum coils contribute to the corrosion resistance of products through the inherent corrosion resistance of aluminum, the even distribution of the material in coil form, the possibility of applying protective coatings, and the use of bimetallic or trimetallic combinations. These factors ensure that products made with aluminum coils have a longer lifespan and are better protected against corrosion in various environments.

- Q: What are the advantages of using aluminum coils in various industries?

- Using aluminum coils in various industries offers several advantages. Firstly, aluminum is lightweight, making it easy to handle and transport. This is especially beneficial in industries like aerospace and automotive, where reducing weight improves fuel efficiency and overall performance. Secondly, aluminum has excellent corrosion resistance. It forms a natural oxide layer that protects it from rust and other forms of corrosion, making it durable and long-lasting. This makes aluminum coils suitable for industries like construction, marine, and HVAC, where exposure to moisture and harsh environments is common. In addition, aluminum has high thermal conductivity, efficiently transferring heat. This makes it ideal for heat exchangers, refrigeration systems, and other applications requiring effective heat dissipation. Moreover, aluminum is highly recyclable, requiring less energy than producing primary aluminum. Using aluminum coils promotes sustainability and reduces environmental impact, making it attractive for companies aiming to adopt eco-friendly practices. Furthermore, aluminum coils can be easily formed and shaped into various sizes and dimensions, allowing for flexible design options and customization. This versatility makes it suitable for a wide range of applications in industries like packaging, electrical, and telecommunications. Lastly, aluminum coils offer cost advantages in terms of initial investment and maintenance. While the upfront cost may be higher than other materials, the long-term benefits of durability, low maintenance requirements, and energy efficiency make it a cost-effective choice. In conclusion, the advantages of using aluminum coils in various industries include lightweight nature, corrosion resistance, high thermal conductivity, recyclability, versatility, and cost-effectiveness. These qualities make aluminum coils a preferred material for many industrial applications, contributing to improved performance, durability, and sustainability.

- Q: What are the potential dangers associated with the use of aluminum coil?

- <p>Aluminum coil, when used in appropriate applications and handled correctly, is generally safe. However, there are some safety risks to consider: exposure to aluminum dust can cause respiratory issues, and improper handling can lead to cuts or burns. Additionally, aluminum can react with certain chemicals, potentially causing hazardous situations. It's important to use personal protective equipment and follow safety guidelines when working with aluminum coil to minimize these risks.</p>

- Q: Is it possible to utilize aluminum coils in creating art pieces or decorative items?

- <p>Yes, aluminum coils can be used to make artworks or decorations. Aluminum's malleability and durability make it an excellent material for crafting. It can be bent, twisted, and shaped into various forms, allowing for creative expression in art and design. Additionally, aluminum's resistance to corrosion and weathering makes it suitable for both indoor and outdoor decorative pieces. Artists often appreciate its lightweight nature and the metallic finish that can be polished or painted, offering versatility in artistic applications.</p>

- Q: How are aluminum coils used in the production of cans and containers?

- Aluminum coils are used in the production of cans and containers as they are rolled into thin sheets that can be shaped into the desired form. These coils are fed into a machine where they are cut, formed, and joined together to create the body of the can or container. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for packaging, ensuring the preservation and protection of the contents inside.

- Q: What are the different coil winding options available for aluminum coils?

- Some of the different coil winding options available for aluminum coils include: 1. Layer winding: This involves winding the aluminum coil in a single layer, where each turn is adjacent to the previous one. This method ensures uniform distribution of the winding and is commonly used for small to medium-sized coils. 2. Pancake winding: In pancake winding, the aluminum coil is wound in a flat, spiral shape. This method is often used for large coils as it allows for efficient use of space and easy handling during transportation. 3. Concentric winding: Concentric winding involves winding the aluminum coil in multiple layers, with each layer placed concentrically around the previous one. This method is suitable for coils that require higher power and voltage ratings. 4. Random winding: Random winding refers to a method where the aluminum coil is wound in a non-uniform or irregular pattern. This technique is typically used for special applications or when the coil needs to fit into a specific space or shape. Overall, the choice of coil winding option depends on factors such as coil size, power requirements, space limitations, and specific application needs.

- Q: Can aluminum coils be used for solar panel applications?

- Solar panel applications can utilize aluminum coils, which are lightweight and durable materials commonly employed in solar panel construction. Aluminum, an excellent conductor of electricity, is ideal for capturing and conducting solar energy. These coils can serve as backing materials for solar panels, offering structural support and aiding in heat dissipation. Furthermore, aluminum possesses good corrosion resistance, a crucial characteristic for solar panels exposed to diverse weather conditions. Ultimately, the strength, conductivity, and corrosion resistance of aluminum coils render them a favored choice for solar panel applications.

Send your message to us

026 Aluminum Coil Hot Rolled Aluminium Circle AA3003 H14

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords