Matte Stainless Steel

Matte Stainless Steel Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleMatte Stainless Steel Supplier & Manufacturer from China

Okorder.com is a professional Matte Stainless Steel supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Matte Stainless Steel firm in China.Hot Products

FAQ

- Steel coils are inspected for hardness using hardness testers by applying a specific amount of force onto the surface of the coil and measuring the depth or indentation left by the indenter. This indentation is then compared to a hardness scale to determine the hardness of the steel.

- The average cost of shipping steel coils can vary depending on various factors such as the distance, weight, size, and mode of transportation. It is recommended to obtain quotes from shipping companies or freight forwarders to get a more accurate estimate based on your specific requirements.

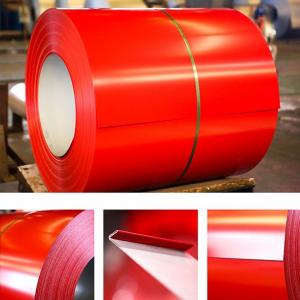

- Yes, steel coils can be coated with chemical-resistant materials. The use of chemical-resistant coatings helps protect the steel coils from corrosion and damage caused by exposure to various chemicals, acids, or solvents. These coatings create a barrier that prevents the chemicals from reaching the steel surface and ensure the durability and longevity of the coils in harsh chemical environments.

- The lifespan of steel coils can vary depending on various factors such as the quality of the steel, the conditions in which they are stored or used, and the maintenance practices employed. However, with proper care and maintenance, steel coils can last for several decades or even longer.

- It seems that steel would be stonger and more stable than wood, fire resistant, and better for the environment, so why are most homes wood-framed rather than steel-framed?

- Because it's always been done that way. Never underestimate inertia when asking why new materials/techniques are not adopted. Besides, the cost does not give steel a clear advantage. You can drive a nail anywhere into a stud. With steel, you have to drill your holes precisely.

- I was wondering if steel cases can be loaded to the same pressure as brass cases. Are the cartridges that commonly feature steel cases like the Russian 5.45x39, 7.62x39 and 7.62x54R loaded to a lower pressure than their C.I.P. MAPs (380 MPa, 355 MPa, 390 MPa --gt; 51,488 psi to 56,564 psi)? There must be a reason why most NATO armies use brass cases...

- The ammo loaded in steel casing has a tendency to be loaded at lower pressures, for some reason. Most if not all of the steel case is of foreign manufacture. No reason steel can't be loaded to same pressures to that of brass, would probably seal better. Most of the calibers you describe in steel cases go in weapons with loose tolerances, like the AK. Lot of times, the steel won't seal in the chamber, creating blow by, putting crud in the chamber. This condition makes it hard to feed, chamber, and extract in a tight dimension chamber that is present in NATO weapons. AK's, due to more generous tolerances, won't be sensitive to this.. Weapons from NATO are of more tightly toleranced chambers like the AR, HK, Barret, etc. where brass is more reliable in sealing, and minimizes the blow by and keeps things clean, or at least more clean than a steel case that may not seal.

- In the manufacturing and processing of steel coils, various steel coil edge treatments are employed. These treatments serve to improve edge quality, protect against damage, and facilitate the handling and processing of the coils. Some of the prevalent types of steel coil edge treatments are as follows: 1. Mill Edge: The steel mill provides this standard edge treatment, which is the raw edge of the steel coil generated during the hot rolling process. The mill edge is typically sharp and may exhibit some irregularities. 2. Slit Edge: Slit edge treatment involves slitting the coil to the desired width and subsequently processing the edges to eliminate any burrs or unevenness. Compared to mill edge coils, slit edge coils have smoother edges. 3. Deburred Edge: The deburring process removes any sharp or rough edges from the coil using specialized equipment or techniques, resulting in a smoother and safer edge. Deburred edges find common use in applications where safety and handling are of utmost importance. 4. Rounded Edge: Rounded edge treatment entails rounding the edges of the coil to minimize the risk of damage during handling and processing. This treatment is frequently employed in applications where the coil must be uncoiled or fed into machinery without incurring any damage. 5. Beveled Edge: Beveling involves chamfering or cutting the edges of the coil at an angle. Beveled edges are utilized in applications where easy insertion, joining, or welding of the coil is required. The beveling process also enhances the strength and durability of the edge. 6. Sheared Edge: Shearing is a cutting process that employs high-pressure blades or scissors to cut the coil to the desired width. Sheared edge treatment yields a clean and straight edge, devoid of burrs or irregularities. It is commonly employed in applications that necessitate precise dimensions and a smooth edge. These are merely a few examples of the various steel coil edge treatments commonly employed in the industry. The selection of edge treatment depends on specific application requirements, such as handling, processing, safety, and aesthetics.