Color Coated Galvanized Corrugated Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Detailed Specifications:

| Product | Color Coated Galvanized Corrugated Steel Sheet |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application of Color Coated Galvanized Corrugated Steel Sheet

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

.Manufacture anticorrosion, industrial and roof boarding,roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils.

.Corrosion resistant parts of cars.

.Food storage, meat and aquatic products’ freezing and processing equipment.

.The equipments to store and transport materials, and packing implements.

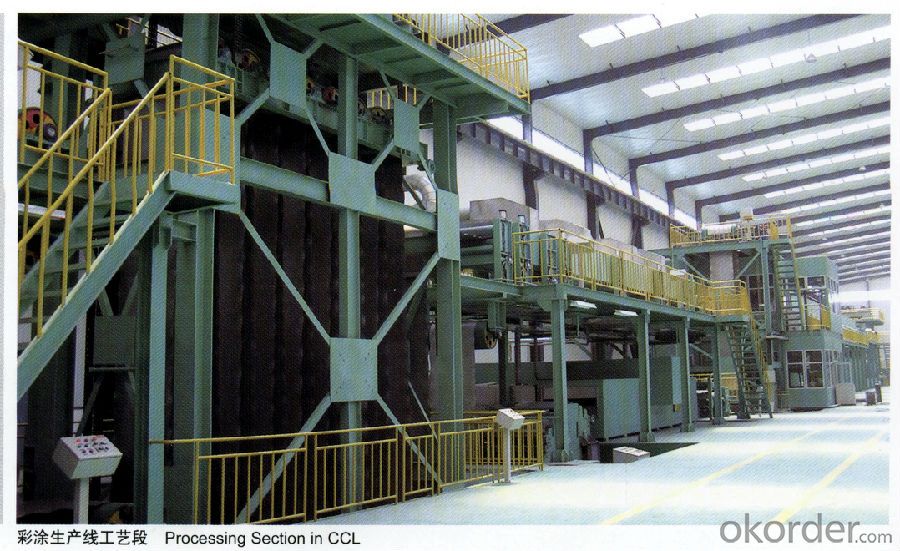

3. Color Coated Galvanized Corrugated Steel Sheet Image:

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel products across various sectors such as construction, automotive, and infrastructure is contributing to the growth of the industry. Steel coils are widely used in these sectors for manufacturing various products such as automobiles, buildings, bridges, and pipelines. Secondly, rapid industrialization and urbanization in emerging economies are fueling the growth of the steel coil industry. Countries like China, India, and Brazil are witnessing significant infrastructure development and construction activities, which require a large amount of steel coils for various applications. Additionally, technological advancements in the manufacturing process and the use of advanced steel alloys are driving the growth of the industry. These advancements have led to the production of high-quality steel coils that offer better strength, durability, and corrosion resistance. Moreover, the growing focus on sustainable and eco-friendly practices is also driving the growth of the steel coil industry. Steel is a highly recyclable material, and the increasing awareness about the environmental benefits of using steel is boosting its demand. Furthermore, favorable government policies and initiatives to promote domestic steel production and reduce imports are also contributing to the growth of the industry. Governments are implementing measures such as import tariffs and subsidies to support local steel manufacturers, which is driving the demand for steel coils. In conclusion, the factors driving the growth of the steel coil industry include increasing demand from various sectors, rapid industrialization, technological advancements, environmental awareness, and supportive government policies.

- Q:What are the different types of packaging for steel coils?

- Steel coils can be packaged in various ways to meet the specific needs and preferences of manufacturers and distributors. Here are some commonly used packaging options: 1. Wooden Crates: To ensure safe transportation and handling, steel coils can be packed in robust wooden crates. These crates, made of durable wood materials like plywood or solid wood, provide excellent protection by securely holding the coils in place. 2. Steel Frames: Another option is to use steel frames, constructed with sturdy steel materials, to firmly secure the coils and prevent any movement or shifting. Steel frames are especially suitable for larger or heavier coils as they offer enhanced stability and durability. 3. Cardboard Boxes: For smaller or lighter steel coils, cardboard boxes can be a suitable choice. These boxes, made of strong and durable cardboard, provide adequate protection against minor impacts and scratches. They are also easy to handle and can be conveniently stacked or stored. 4. Plastic Wrapping: In addition to crates, frames, or boxes, steel coils can be wrapped in plastic materials for added protection. Plastic wrapping safeguards the coils from moisture, dust, and external elements during transportation and storage. This packaging option is commonly used in combination with other methods. 5. Transportation Racks: Specially designed transportation racks made of steel or other robust materials can be used for efficient handling and transport of steel coils. These racks securely hold the coils, allowing for easy loading and unloading, and ensuring enhanced safety during transit. Overall, the choice of packaging for steel coils depends on factors such as size, weight, transportation method, and desired level of protection. Manufacturers and distributors carefully consider these factors to select the most appropriate packaging solution that ensures the safe and efficient handling of steel coils throughout the supply chain.

- Q:How are steel coils used in the production of power transmission towers?

- Steel coils are used in the production of power transmission towers as they provide the necessary strength and durability to support the towers and withstand the transmission lines' weight and environmental conditions. The steel coils are shaped and welded into various sections and components, such as the legs, base plates, and cross arms, which are then assembled to create the tower structure. The coils' high tensile strength ensures the towers can withstand the mechanical stresses and loads imposed by the transmission lines, making them a crucial component in the construction of power transmission towers.

- Q:If rail ties were melted, would they be like any other type of steel?

- If you were to melt rail steel down and pour it into ingots, I doubt anyone would check to find it's source although a skilled metalurgist would know. While the steel was melted you could toss a handful of old horseshoes in and change the composition and no one would know. Good luck with your project, I would like to know how it turns out.

- Q:How are steel coils stored and transported?

- Steel coils are typically stored and transported in a horizontal position, either on the ground or on specially designed racks. They are often secured with steel straps or bands to prevent movement or damage during transportation. When being transported, steel coils are typically loaded onto flatbed trucks or shipping containers using cranes or forklifts. The coils are then secured in place with additional straps or chains to ensure stability during transit.

- Q:What are the dimensions and weight range of steel coils?

- Steel coils can come in various dimensions and weight ranges depending on the intended use and industry requirements. The dimensions of steel coils typically range from 0.15mm to 3.5mm in thickness, and from 600mm to 2,000mm in width. The weight range of steel coils can vary widely, but commonly falls between 5 and 25 metric tons. The specific dimensions and weight range of steel coils are determined by factors such as the type of steel, the production method, and the desired application.

- Q:How are steel coils protected against scratches and damage?

- Steel coils are protected against scratches and damage through a variety of methods. One common method is the application of a protective coating or film on the surface of the coils. This coating acts as a barrier, preventing direct contact between the steel surface and any potential sources of scratches or damage. The protective coating can be made of materials like polyethylene, PVC, or other types of plastic that are resistant to abrasion and impact. Additionally, steel coils are often wrapped or packaged using materials such as paper, cardboard, or plastic. This wrapping provides an extra layer of protection against scratches and damage during storage, transportation, and handling. The wrapping material acts as a cushion, absorbing any potential impacts or friction that could lead to scratches. Furthermore, steel coils may be stored and transported in specially designed containers or pallets that are equipped with features to minimize the risk of damage. For instance, these containers or pallets may have padded interiors, secure fastenings, or dividers that keep the coils in place and prevent them from rubbing against each other. In some cases, steel coils are also stored or transported in a controlled environment to minimize the risk of damage. This can include temperature-controlled warehouses or shipping containers that help to prevent the formation of moisture, which can lead to corrosion or other types of damage. Overall, a combination of protective coatings, wrapping materials, specialized containers, and controlled environments is employed to ensure that steel coils are adequately protected against scratches and damage throughout their lifecycle.

- Q:Where are the coils and the steel plates used? Where did the steel plate come from?

- The use of steel coils, refrigerators, washing machines, household appliances, and other industries, parcels are winding.Steel plates can also be found everywhere: airplanes, guns, trains, ships, space shuttles, spaceships, automobiles, etc..Steel plate through mining - sintering - iron smelting - smelting - forming.

- Q:Does the solution change, or does only the steel wool change color?

- once you upload water to anhydrous copper(II) sulphate it turns blue because of the fact that's going to become hydrous copper(II) sulphate. Then, in case you upload water greater, that's going to proceed to be blue, could be slightly darker.

- Q:How are steel coils used in construction?

- Steel coils are commonly used in construction for a variety of purposes, such as creating structural frameworks, reinforcing concrete, and manufacturing various building components like beams, columns, and trusses. The coils are unrolled and cut to specific dimensions, allowing them to be easily shaped and welded into various structural elements. This versatile material provides strength, durability, and flexibility, making it an essential component in constructing buildings, bridges, and other infrastructure projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Galvanized Corrugated Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords