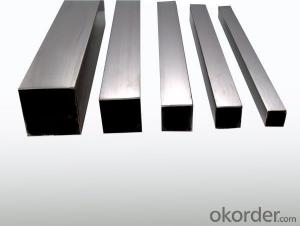

Stainless steel tube ; square tube

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | JIS,AISI,ASTM,GB | Place of Origin: | China (Mainland) | Model Number: | 304 316L 310S |

| Type: | Welded | Steel Grade: | 200 series,300 series,900 series | Application: | light industry,heavy industry,daily necessities and the decoration ind |

| Certification: | SGS | Thickness: | 0.3-100mm | Outer Diameter: | 6-1000mm |

| Item: | stainless steel square tube/pipe | Cetification: | SGS | Welding Line type: | welded |

| Quality: | High quality tube stainless steel | Package: | In plastic wrapper/wooden case/according to your requirements | Delivery: | In 15 days |

| Stock: | Available |

Packaging & Delivery

| Packaging Detail: | In plastic wrapper/wooden case/according to your requirements |

| Delivery Detail: | In 15 days |

Specifications

stainless steel square tube/pipe

T :o.3-100mm

OD:6-1000mm

Finish: bright

Quality: Top quality tube stainless steel

stainless steel square tube/pipe

Thickness:1-100mm

Outer Diameter:10-1000mm

Welding line type: ERW

Item | High quality stainless steel tube price |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc |

Material | 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L 302,301,201,202,403,405,409,409L,410,410S,420,430,631,904L,Duplex,etc |

Thickness | 1-100mm |

Outer Diameter | Customized |

Welding line type | welded or seamless |

Package | Standard export package, suit for all kinds of transportation, or as required. |

Price term | Ex-Work, FOB, CNF, CFR, CIF, FCA, DDP, DDU, etc |

Payment term | T/T,L/C,DP,Western union |

MOQ | 500Kg |

Application | Stainless steel tube applies to construction field, ships building industry, Stainless steel tube can be made according to the customers’ requirements. |

Contact | If you have any question, please feel free to contact us. We believe customers first! |

- Q:Can stainless steel pipes be insulated with silicone?

- Yes, stainless steel pipes can be insulated with silicone. Silicone is a versatile material that can withstand a wide range of temperatures, making it suitable for insulating pipes that carry hot or cold fluids. Silicone insulation is typically available in the form of sleeves or wraps that can be easily applied to the pipe surface. It provides excellent thermal insulation, preventing heat loss or gain from the pipe and improving energy efficiency. Additionally, silicone insulation is resistant to moisture, chemicals, and UV radiation, ensuring long-lasting performance.

- Q:What is the difference between polished and unpolished stainless steel pipes?

- The main difference between polished and unpolished stainless steel pipes lies in their appearance and surface texture. Polished stainless steel pipes have undergone a process to enhance their visual appeal, resulting in a shiny, mirror-like finish. On the other hand, unpolished stainless steel pipes maintain their natural, raw surface texture, which may appear duller and less reflective. The choice between polished and unpolished stainless steel pipes depends on the desired aesthetic and the specific application requirements.

- Q:What is the typical wall thickness of stainless steel pipes?

- The typical wall thickness of stainless steel pipes can vary depending on the specific application and industry requirements. However, it is common to find stainless steel pipes with wall thickness ranging from 0.065 inches (1.65 mm) to 0.250 inches (6.35 mm).

- Q:Why is the outer diameter of 1 inch galvanized pipe 33.7? And the outer diameter of one inch stainless steel pipe is 25.4

- The 1 inch galvanized pipe refers to the nominal size holes of 1 inches of water, the outer diameter is 33.7, its diameter fits a 1 inch pipe thread wire, and one inch stainless steel tube outer diameter is 25.4 that of the tube is in diameter standard specifications.

- Q:What is the difference between 304 and 316 stainless steel pipes?

- 304 and 316 stainless steel pipes are both commonly used in various industries due to their excellent corrosion resistance and durability. While they may appear similar, there are notable differences between the two grades: 1. Composition: The primary difference lies in their composition. 304 stainless steel pipes contain 18-20% chromium and 8-10.5% nickel, while 316 stainless steel pipes contain 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. This additional molybdenum in 316 stainless steel enhances its corrosion resistance, particularly against chlorides and other aggressive chemicals. 2. Corrosion resistance: 316 stainless steel pipes offer superior corrosion resistance than 304 stainless steel pipes, especially in environments with high chloride exposure such as coastal areas or industrial settings with corrosive chemicals. The molybdenum content in 316 stainless steel provides enhanced resistance against pitting and crevice corrosion. 3. Temperature resistance: Both grades of stainless steel pipes exhibit good resistance to high and low temperatures, but 316 stainless steel pipes perform better under extreme temperature conditions. They can withstand higher temperatures and have better strength retention compared to 304 stainless steel pipes. 4. Applications: Due to its superior corrosion resistance, 316 stainless steel pipes are commonly used in industries such as marine, chemical processing, pharmaceuticals, and food processing. On the other hand, 304 stainless steel pipes find applications in various industries including automotive, construction, and appliances. 5. Cost: 304 stainless steel pipes are generally more affordable compared to 316 stainless steel pipes due to the difference in their composition and availability. However, the specific application and required corrosion resistance should be considered when determining the cost-effectiveness of each grade. In summary, while both 304 and 316 stainless steel pipes offer excellent corrosion resistance and durability, the addition of molybdenum in 316 stainless steel provides superior resistance to chloride corrosion. The choice between the two grades depends on the specific application, budget, and the level of corrosion resistance required.

- Q:304 stainless steel seamless tube weight how to calculate?

- The common marking methods in the market are 00Cr19Ni10, SUS304, in which 00Cr19Ni10 is generally used to indicate standard production of the national standard. Generally speaking, ASTM standard production is indicated, and SUS 304 represents standard production.

- Q:Can stainless steel pipes be used for food processing?

- Yes, stainless steel pipes are commonly used in food processing due to their hygienic properties, corrosion resistance, and durability.

- Q:Are stainless steel pipes suitable for chemical storage tanks?

- Yes, stainless steel pipes are typically suitable for chemical storage tanks. Stainless steel is highly resistant to corrosion and can withstand the harsh chemicals stored in tanks, making it a preferred material for chemical storage applications.

- Q:How do you prevent contamination in stainless steel pipes?

- To prevent contamination in stainless steel pipes, proper cleaning and maintenance practices should be followed. This includes regular inspection and removal of any buildup or deposits, ensuring that the pipes are properly sealed to prevent ingress of contaminants, and avoiding contact with substances that can cause corrosion or contamination. Additionally, implementing a proper filtration system and adhering to recommended hygiene protocols can further prevent contamination in stainless steel pipes.

- Q:Can stainless steel pipes be insulated with foam?

- Yes, stainless steel pipes can be insulated with foam. Foam insulation is commonly used to insulate pipes of various materials, including stainless steel. Foam insulation provides thermal resistance and helps to prevent heat loss or gain from the pipes. It also helps to minimize condensation on the surface of the pipes, which can prevent corrosion. Foam insulation can be easily applied to stainless steel pipes using adhesive or tape, and it can be customized to fit the specific dimensions of the pipes. Overall, foam insulation is an effective and cost-efficient solution for insulating stainless steel pipes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless steel tube ; square tube

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords