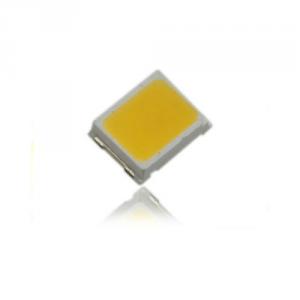

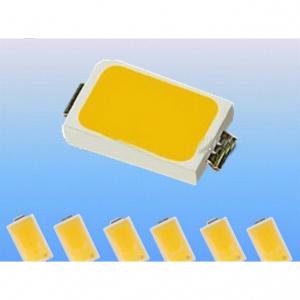

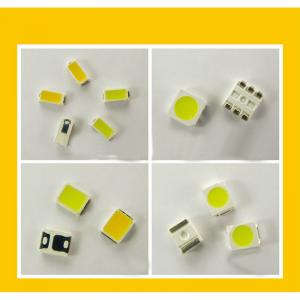

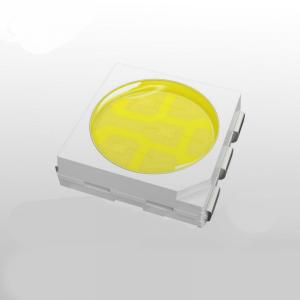

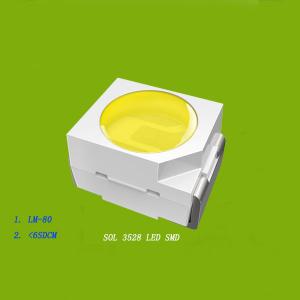

Led Smd 2835 Datasheet

Led Smd 2835 Datasheet Related Searches

Led Smd 2835 DatasheetHot Searches

Nature Stone CostLed Smd 2835 Datasheet Supplier & Manufacturer from China

Okorder.com is a professional Led Smd 2835 Datasheet supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Led Smd 2835 Datasheet firm in China.Hot Products

FAQ

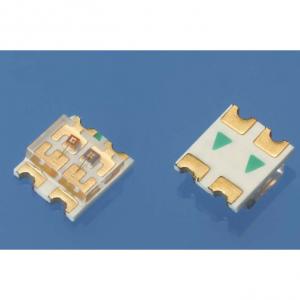

- Notes on patch LED

- Storage bags are sealed and stored at a temperature of <40 DEG C.

- What is the difference in performance between the LED plug-in and the LED patch?

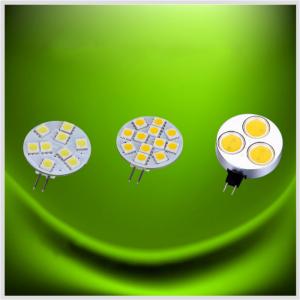

- The cooling of the plug-in is not good, because the plug-in's lamp foot, in order to save costs, generally use iron plus coating, heat conduction is not very good.The strength of aluminium alloy is not enough, it is easy to break, and copper is expensive.Relatively speaking, the patch is good, because the heat is welded on the PCB, copper or direct aluminum substrate cooling, patches near.Otherwise, why do high-power patch it?!SMT direct placement machine, a high degree of automation, low rate of bad.

- SMD LED lamp working voltage?

- Voltage range of white LED lamp: 3.0-3.4VThe pressure drop of the red LED is 2.0--2.2VThe yellow light emitting diode has a pressure drop of 1.8 - 2.0VThe green light emitting diode has a pressure drop of 3 - 3.2VThe blue light emitting diode has a pressure drop of 3.0-3.4VSMD voltage is basically the same as double lead line. Current is generally 20~60mA, and some work current can exceed 100mA.

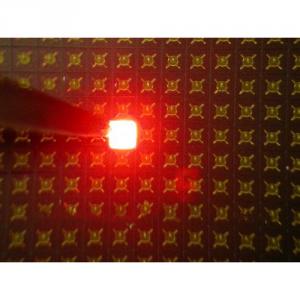

- How to detect LED SMD beads

- The output voltage of the digital clock diode file is not high, generally below 2.5V, so the measurement of LED lamp does not work, the best way is to external electrical measurement. If there are a lot of beads to measure it, can take a constant current power measurement.

- What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- I recommend reflow soldering under normal conditions and manual welding only when repaired. 2 manual soldering electric soldering iron maximum power can not exceed 30W, welding temperature is controlled within 300 degrees, welding time less than 3 seconds. 3 do not touch the colloidal iron welding head. 4 when the pin is heated to 85 degrees centigrade or higher than this temperature, it can not be pressed. Otherwise, the welding will be broken.

- What determines the brightness of the patch LED?

- The current through the lamp itself. If the same lamp, so it is necessary to ensure consistency in the different current circuit, the test voltage of little significance, especially in the case of parallel lamp, current a few beads each share is not the same, some big, some small.

- Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- LED high power and low power, small white rated current and LED wafer, such as a chip is 20MA two 40MA.... High power 0.5W, 100-150MA, 1W, 350MA current rating in the relevant product specifications

- LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- Of course, the reflow soldering is generally divided into three sections of six principle of oven temperature is 150 degrees, 190 degrees, 220 degrees, with a PC lens products can not reflow soldering, PC deformation at 150 degrees, can be heated by a soldering paste on the heating plate.