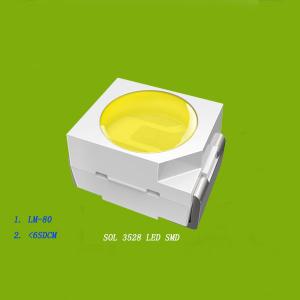

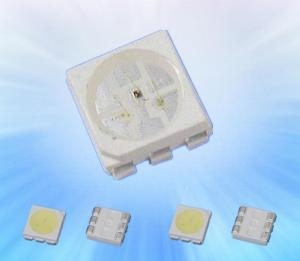

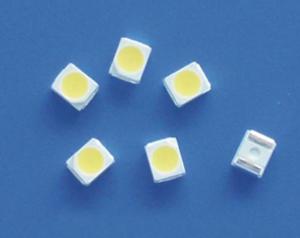

0.2W 20 to 25Lm 5050 White Top SMD LED

- Loading Port:

- Xiamen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 10000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

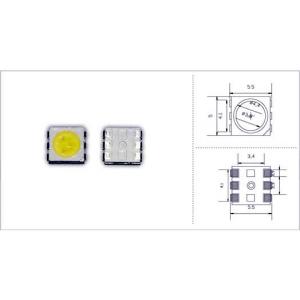

0.2W white 5050 top smd LED, 20-25lm/pc, CRI>80,dimension:5.0mm*5.0mm*1.6mm, 2kpcs per reel.

Advantages

1/ LED is RoHS compliance.

2/ Luminous fading less than 6.9% after 30,000hours, which is compliant to LM80 lab test.

Application:

Available for light souce of LED lights, such as LED tube, LED bulb, LED ceiling light, LED panel, LED downlight, etc.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q:What does "1210" mean in patch LED?

- 1210 refers to the lamp specifications.LED common lamp specifications and parameters of patch0603, 0805, 1210, 3528, 5050 refers to the LED lamp belt, often used in light-emitting components ----LED size (English / Metric) name, for example, 0603 refers to the length of 0.06 inches, width of 0.03 inches. But note that the 3528 and 5050 units are metric

- Q:How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- With double-sided adhesive, the temperature will not be very high. So it won't fall either. That's how I got it. It took me more than half a year, and I didn't have any problems

- Q:What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- At present, it is basically made of silica gel, and the epoxy resin is very few. Only those with lower price may use some. Why is it rare to use epoxy? Because of the use of LED epoxy patch cited some discomfort because the cable used in the above: reflow welding, high temperature resistant epoxy epoxy and silicone not lead to separation, produce decay dead lights etc..

- Q:Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- If you choose the brightness of blue light in the light of the relatively high, so when debugging the white balance (by changing the resistance to change the current, and then change the RGB brightness LED lamp), it is difficult to transfer to the pure white. Therefore, when selecting the lamp, the blue light is generally not bright.

- Q:What is the difference in performance between the LED plug-in and the LED patch?

- 1, the patch is relatively easy to heat dissipation, can be directly welded on the aluminum substrate, heat faster.2, in general, there is a straw type shell, general lighting has front facing directivity, just look at it, brightness will be the biggest. The patch has a relatively wide divergence angle and is more suitable for fluorescent lamps.

- Q:How do led patches measure good or bad?

- Use the two stage tube test of the multimeter, the red pen is connected, and the black pen is negative. If there is a bee, the sound is bad, and if the light is bright, it is good

- Q:LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- Chip and stent welding methods are: eutectic welding, silver glue fixed, resin insulation and fixed silicone rubber insulation fixedWelding beads: reflow soldering, hot plate welding and manual soldering.

- Q:What is patch SMD-LED?

- This really do not know how to answer you, like a sheet of the same type of solder paste used to operate, it can be said that the plug-in is not, it is patch it!

- Q:What are the storage requirements of SMT patch LED (LED)?

- Clean? use no designated chemical liquids to clean SMD LED. These chemicals may damage SMD LED.. When necessary, wipe LED at room temperature with alcohol and dry at room temperature for 15 minutes before use? the effect of ultrasonic cleaning on SMD LED is related to the ultrasonic power and the SMD LED assembly method, and shall be checked in advance to ensure that the ultrasonic cleaning process does not impair the SMD LED

- Q:Patch LED features

- The principle of luminescence is that of cold luminescence, not by heating or discharging light, so the component life is about 50~100 times longer than that of tungsten filament bulb, and about one hundred thousand hours.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

0.2W 20 to 25Lm 5050 White Top SMD LED

- Loading Port:

- Xiamen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 10000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords