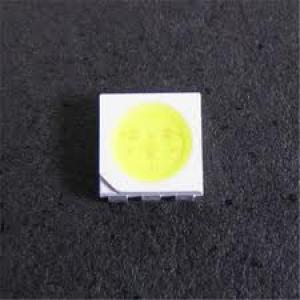

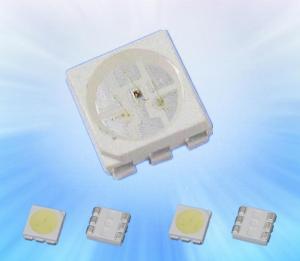

High Lumen 60-65Lm White SMD LED 5730 For LED Bulb

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1 Pc pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications for 5730 smd led white color

| Model | Power | color | intensity | voltage | current | view angle | CCT |

| SL-WZ5730-EM | 0.5w | white | 60-65lm | 2.8-3.5v | 150mA | 120deg | 5500-6000k |

| SL-IZ5730-EM | 0.5w | warm white | 55-60lm | 2.8-3.5v | 150mA | 120deg | 2850-3150k |

(Electro-Optical Characteristics(Ta=25°C)

Parameter | Test condition | Symbol | Value |

Forward voltage | If=150mA | Vf | 2.8-3.5v |

Luminous Flux | If=150mA | Φ | 60-65lm |

Viewing angle at 50% Iv | If=150mA | 2θ 1/2 | 120 Deg |

Reverse current | Vr=5v | Ir | 10µA |

Ra | If=150mA | Ra | 70/80/90 |

Absolute maximum ratings (Ta=25°C)

Parameter | Symbol | Value |

Power dissipation | Pd | 700mW |

Forward current | If | 200mA |

Reverse voltage | Vr | 5V |

Operation temperature range | Top | -35~+85°C |

Storage temperature range | Tstg | -40~+100°C |

Pulse forward current | Ifp | 250mA |

Electrostatic discharge | ESD | 2000(HBV)V |

Soldering temperature | Tsld | 260°C for 10 seconds |

Junction temperature | Tj | 105°C |

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q:How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- Installed indoors, you can directly tear off the stickers on the 3M double-sided adhesive surface, and then fix the light bar where it needs to be installed. Just press it with your hands.

- Q:What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- The main difference is the encapsulation method. The liquid silicone is mainly encapsulated and encapsulated, while the gum cake is solid and adopts a transfer molding package. Of course, there is a fundamental difference between the material, silica gel can be used for white light high-power LED, suitable for lighting. The epoxy can only be used in low-power monochrome LED, suitable for display, backlight, induction and other components.

- Q:How many volts is a single LED on the LED patch band?

- LED patch lamp is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.

- Q:Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- When making a batch of LED lights, the brightness values of various lights are in accordance with certain rules. Due to achieve a white balance, three RGB color brightness required by the ratio of 3:6:1, that is to say the blue light required brightness is very low.

- Q:SMD LED lamp working voltage?

- Single chip of 1 watts, more than a lot, different colors, the voltage will be different. White is usually 3.0-3.6V.* in addition to their working voltage, working current is more important parameters, once the flow, it will burn out.The LED lamp. With chips is variety, many tricks, they can be connected in series and parallel. The voltage is divided into high voltage, low voltage and medium voltage

- Q:LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Packaging is for TOP series LED, that is, the type of plastic molding. The patch is based on the PCB circuit board for molding. Mold release agent is used in molding.

- Q:What determines the brightness of the patch LED?

- Lamp brightness level itself, is also in the rated current situation, its brightness

- Q:How do led patches measure good or bad?

- Use the two stage tube test of the multimeter, the red pen is connected, and the black pen is negative. If there is a bee, the sound is bad, and if the light is bright, it is good

- Q:What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

- Q:Patch LED features

- The seismic resistance, high reliability, low operation cost system.It is easy to small, thin, lightweight, easy to shape without restrictions, made all kinds of application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Lumen 60-65Lm White SMD LED 5730 For LED Bulb

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1 Pc pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords