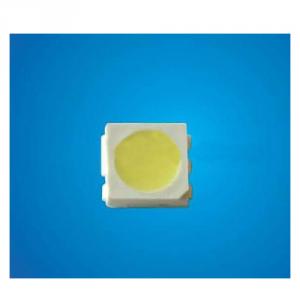

LED SMD 5730 50-55LM 2700-7500K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

LED SMD 5730 50-55LM 2700-7500K Regular color temperature:

warm white 2600-2900K,2900-3200K,3000-3500K

natural white 4000-4500K,4500-5000K

cool white 5000-5500K,5500-6000K,6500-7000K

cold white 7000-9000K,9000-15000K

Available SMD type:

3528, 2835, 5050, 5730, 3034

Stable quality w

warm white 2600-2900K,2900-3200K,3000-3500K

natural white 4000-4500K,4500-5000K

cool white 5000-5500K,5500-6000K,6500-7000K

cold white 7000-9000K,9000-15000K

Available SMD type:

3528, 2835, 5050, 5730, 3034

Stable quality w

- Q:Patch LED beads can be bought in what place?

- Many LED packaging plants do patch LED, you can find the relevant manufacturers to contact, or go to the local electronic components market according to your needs

- Q:What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

- Q:The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- Shunt split current series split voltageIs your single lamp voltage rated voltageIn addition to the red and green LED lights, the voltage is between 2 and 2.4, and the other colors are 3 to 3.6V

- Q:What is patch LED?

- LED is usually the lead pins form, need to be drilled on the printed circuit board, the LED pin is inserted in the hole, welded with wave soldering machine; and the patch type LED is used in welding surface, flat welded on the circuit board.

- Q:Patch LED market conditions

- Chinese suppliers also offer mature, but less profitable two-color and trichromatic products, which are mostly used in backlighting, appliances, consumer products, consumer electronics and display. Despite low market demand, vendors continue to offer sideview SMD LED, including 335 (4008), 020 (3806) and 215 (2810)

- Q:LED light SMD LED package in what form, trouble you under the guidance of...

- The LED chip has bumps and is welded to the PCB board using FLIP CHIP to packaging technology.LED is English light emitting diode (light emitting diode) abbreviation, its basic structure is a electroluminescent semiconductor chip light emitting materials, with silver glue or glue curing to the bracket, connecting a chip and a circuit board and then with silver or gold, then sealed with epoxy resin around, to protect the internal core role finally, the installation shell, so the seismic performance of LED lamp is good. Field of application involves mobile phones, desk lamps, household appliances and other daily household electrical appliances and machinery production.

- Q:LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Mold release agent is a functional substance between the mold and the finished product. The release agent is chemically resistant and is not soluble in contact with the chemical constituents of different resins (especially styrene and amines). Release agent also has heat and stress properties, not easy to decompose or wear; release agent bonded to the mold, and not transferred to the processed parts, without prejudice to painting or other two processing operations. Because of the rapid development of injection molding, extrusion, calendering, molding and laminating, the dosage of mould release agent is greatly improved.

- Q:Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- The high power 1W is 350MA, and 3W is 700MA. They are all fixed and can be found everywhere.

- Q:LED patch lamp band, how to calculate how many watts a meter, such as 3528-60 beads is how much?

- LED patch lamp with 3528-60 beads should be 4.8W/ meters.Because the LED light belt is made according to the manufacturer's standard, the parameters are different, and the parameters of the LED lamp belt and the method of use are best connected with the manufacturer's confirmation. Some common parameters are given here for reference only

- Q:What is patch SMD-LED?

- Semiconductor wafers consist of two parts, one is P type semiconductor, in which the hole dominates, and the other end is N type semiconductor, which is mainly electronic here. But when the two semiconductors are connected, they form a P-N junction between them. When the current passes through the wire acting on the chip, the electrons are pushed into the P region. In the P region, electrons combine with the hole and then emit energy in the form of photons, which is the principle of LED luminescence. The wavelength of light, that is, the color of light, is determined by the material that forms the P-N junction.

The total area of 25,000 square meters. Company R & D, production, sales, service integration, professional development and production of high brightness - blue-white, pure purple pure green ﹑ series of high-end full-color LED (light emitting diode).

1. Manufacturer Overview |

|

|---|---|

| Location | Shenzhen,China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | Mid East;Western Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | About 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Cheap |

Send your message to us

LED SMD 5730 50-55LM 2700-7500K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords