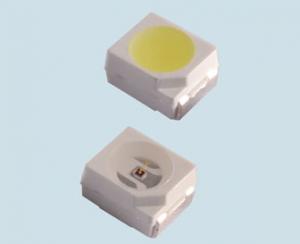

LED SMD 3528 Yellow Light

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LED SMD 3528 Yellow Light Regular color temperature: warm white 2600-2900K,2900-3200K,3000-3500Knatural white 4000-4500K,4500-5000Kcool white 5000-5500K,5500-6000K,6500-7000Kcold white 7000-9000K,9000-15000KAvailable SMD type:3528, 2835, 5050, 5730, 3030Stable quality w0, 5730, 3030Stable quality with low optical attenuation1000h<1%, 3000h<3%, 10000h<8%A. Meet CE, FCC, RoHS, EMC,LVD certification;B. No RF interference, no buzzing noise and no UV radiation;C. Low power consumption, high intensity low lumen attenuation and wide range of available operating voltage; D. Easy to install and maintain,replacement of traditional bulbs;E. Environment-friendly, No hazard of mercury or lead entering the environment.F. High efficiency and energy-saving compared to conventional fluorescents which are equal bright, an

- Q:What does "1210" mean in patch LED?

- At present, most manufacturers of SMD light strip used by 3528 and 5050, and 3535 and 5630 in the majority, there are many of the 3528 and 5050 and 3535, such as patch LED used in automotive lighting.

- Q:How many volts is a single LED on the LED patch band?

- 3V or so, generally three, a group plus a resistor, power supply with 12V

- Q:Which is good for LED patch and LED bulb?

- Chip LEDLED patch lamp (SMD) is made of FPC circuit board, LED lamp and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbThe light emitting diode, is capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light; LED Large Electronic = Display, LED = large electronic display; Lupus erythematosus disseminatus, systemic lupus erythematosus, a chronic idiopathic autoimmune disease; LED lead the past and past participle, meaning "leadership, led the Russian Pulkovo Airport IATA code.

- Q:Is the forward voltage drop of the patch LED too large or too small?

- The pressure drop in the normal range is generally better. The smaller the pressure drop, the lower the power dissipation. The more you save the electricity bill.But not to say that the smaller the better, not in the normal range of low pressure drop products may be defective.In addition, the uniformity of the LED pressure drop is also important.

- Q:What is the principle used in SMD LED lamp, should pay attention to what the problem?

- Table 1, contact electrostatic protection LED product should be covered with protective electric tape, and its reliable grounding; 2, personnel shall wear groundstrap in contact with LED (best for cable, protective gloves, anti-static ring) allows better wear anti-static clothing, anti-static shoes and static electricity cap; 3, the application in the process of exposure to LED equipment must be reliable grounding, such as iron, shearing machine, bending machine and welding equipment. Conditional still can install plasma fan to eliminate electrostatic; 4, in use or when designing electronic circuit, must consider the harm that excessive current has to LED

- Q:0603,0805,1206,3020,3528,5050,355 what is the current and voltage of these patch LED? Please give advice!

- The patch LED is also called SMD LED. Its principle of luminescence is to pass the current through the compound semiconductor. Through the combination of the electron and the hole, the excess energy will be released in the form of light to achieve the effect of luminescence.

- Q:LED light SMD LED package in what form, trouble you under the guidance of...

- There are 3 types of LED packages: inline LED, piranha LED, and surface mount LED

- Q:LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Mold release agent is a functional substance between the mold and the finished product. The release agent is chemically resistant and is not soluble in contact with the chemical constituents of different resins (especially styrene and amines). Release agent also has heat and stress properties, not easy to decompose or wear; release agent bonded to the mold, and not transferred to the processed parts, without prejudice to painting or other two processing operations. Because of the rapid development of injection molding, extrusion, calendering, molding and laminating, the dosage of mould release agent is greatly improved.

- Q:Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- LED high power and low power, small white rated current and LED wafer, such as a chip is 20MA two 40MA.... High power 0.5W, 100-150MA, 1W, 350MA current rating in the relevant product specifications

- Q:What are the storage requirements of SMT patch LED (LED)?

- Moisture-proof packing- anti SMD LED in the transport and storage of moisture absorption, SMD LED shall be placed in sealed moisture-proof bag, inside put damp proof agent for protection, and placed the humidity humidity SMD display card packaging bag.

1. Manufacturer Overview |

|

|---|---|

| Location | Shenzhen,China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | Mid East;Western Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | About 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Cheap |

Send your message to us

LED SMD 3528 Yellow Light

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords