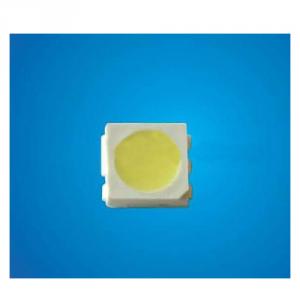

High Cri 5630 SMD LED (Ra95)

- Loading Port:

- Beijing

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

High Cri 5630 SMD LED (Ra95)

Features

-High CRI (Ra > 95, R9 > 90) to illuminate objects' true colors

-Full emission spectrum close to sunlight

-Half-power emission angle: 120°

-Internal structure: Aluminum base covered by silver

-Warm white and normal white available

-RoHS compliant

- 5.6mm*3.0mm surface-mount

Applications

Accent lighting products:

Photography lights

Museum and art gallery lighting

High-end shopping center

Exhibition or visitor center

Food display in supermarket

Hospitality or bar light

Hospital lighting

General indoor lighting

Electronic Products:

Display

Back-light unit

Medical equipment lighting

Optoelectronic Parameters (Ta=25°C)

Specification

Item | Symbol | Min | Typical | Max | Unit | Condition | |

Luminous flux | IV | 20 | ---- | 27 | lm | IF=120mA | |

HP Angle* | 2θ1/2 | ---- | 120 | ---- | Deg. | IF=120mA | |

Color Temp | Normal White | CCT | 4000 | ---- | 5000 | K | IF=120mA |

Warm White | CCT | 3000 | ---- | 4000 | K | IF=120mA | |

Forward voltage | VF | 3.3 | ---- | 3.5 | V | IF=120mA | |

Reverse current | IR | ---- | ---- | 5 | μA | VR=5V | |

Color Rendering | Ra | 95 | ---- | 98 | ---- | IF=120mA | |

Note

Half-power emission angle is calculated asθ1/2, where 2θ1/2 = θ1/2 + θ1/2

Our Service

With the continued development of LED technology and the expansion of LED applications, users are no longer only pursuing LED light efficiency and brightness. Instead, high CRI (Color Rendering Index) and tight binning (exact color temperature) are becoming two of the most important considerations for lighting designers, especially for those looking for accent lighting in order to show objects’ colorful appearance or create a certain atmosphere.

Advantages

1. R & D capabilities. We have our own LED packaging and LED phosphor research & production centers, by which we are able to develop our industry-leading technology to strictly control the light quality.

2. High color rendering. In addition to the CRI value (R1-R8 average), we focus on each R value. This is the only way that CRI be truly meaningful to evaluate the LED’s color rendering ability. Particularly, R9 (red) and R12 (blue) are difficult to improve, but meanwhile, indispensable in showing skin tones, foods, fabrics, etc.

3. Light efficiency. Most LEDs with claimed CRI 95 in the market have relative low luminous efficiency than normal LED. We are using the best LED chip and phosphors to keep our light efficiency competitive given CRI 95.

4. Excellent team. We have passionate members with expertise knowledge.

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q:What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- At present, it is basically made of silica gel, and the epoxy resin is very few. Only those with lower price may use some. Why is it rare to use epoxy? Because of the use of LED epoxy patch cited some discomfort because the cable used in the above: reflow welding, high temperature resistant epoxy epoxy and silicone not lead to separation, produce decay dead lights etc..

- Q:Which is good for LED patch and LED bulb?

- The LED patch is the same as the LED bulbLED (light emitting diode) patch (package)The LED patch (SMD) is made of FPC circuit board, LED and high quality silica gel sleeve. Waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising and entertainment quasi decorative lighting lighting field.LED bulbWith the LED patch or LED plug-in LED (light emitting diode), series or parallel, driving power supply, making a combined shell lampshade capable of converting electrical energy into visible solid semiconductor devices, which can be directly converted into electricity to light.

- Q:What is the difference between patch LED beads and LED beads: General

- A pin of the lamp, and outside a resin cap, because the reason LED beads can spotlight cap;There is no pin on the patch and there is no resin cap outside. Because of the lack of cap, the LED patch can not be concentrated.Patch is based on small power, the shape is relatively small (usually 0.5 and 0.5W products)It's called patch because some small ones need Mounter to machine.The ordinary LED lamp, solder joints than SMD beads, now is the largest artificial welding. Regular watts count from 1-300W

- Q:Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- First of all, welding LED and other electronic products with line electrostatic ring, to prevent static light.When welding the patch LED lamp, first add the tin on the pad of the lamp board, then clamp the LED patch lamp with tweezers. Then, the soldering iron will melt the tin of the solder plate of your lamp board, and then push the LED lamp onto the pad with tweezers. The whole welding process should not exceed 5 seconds, otherwise it will burn the lamp easily.

- Q:What is the difference in performance between the LED plug-in and the LED patch?

- The same, stick pieces is an early product, stick pieces than patch mature, stick pieces of my lamp has almost can not see what changes for three years with only a patch of brightness, years have been feeling a lot of dark. I believe the quality will be good soon.

- Q:What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The peak reflow temperature: 260 degrees or below this temperature. (surface temperature) 2 temperature over 210 DEG C required time: 30 seconds or less than this time. 3 reflow times: no more than two times. 4 after reflow, LED needs to be cooled to room temperature before contact with colloid.

- Q:LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Packaging is for TOP series LED, that is, the type of plastic molding. The patch is based on the PCB circuit board for molding. Mold release agent is used in molding.

- Q:How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- The light emitting diode is fixed regardless of color. The light emitting diode 1, line: foot length is positive, the negative is short. The electrodes inside the tube can also be carefully observed, while the smaller ones are positive and the large ones, similar to the bowl, are negative. 2, SMD: overlooking the side with the color line is negative, the other side is positive.

- Q:What determines the brightness of the patch LED?

- The brightness is consistent over a short period of time, that is, only by considering current and voltage consistency.Long term brightness is consistent with the consideration of the spacing and heat dissipation of different circuits. Uneven heat can also affect brightness.

- Q:What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Cri 5630 SMD LED (Ra95)

- Loading Port:

- Beijing

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs bag

- Supply Capability:

- 100000 Pcs Per Month bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords