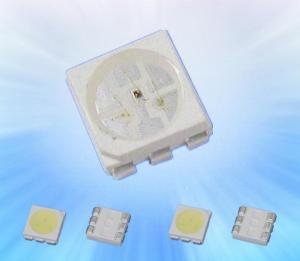

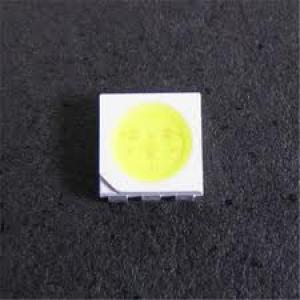

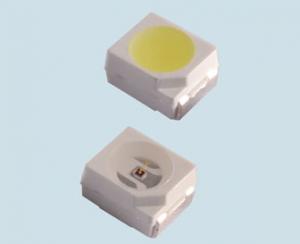

LED SMD 5050 22-24lm 6000-7000K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LED SMD 5050 22-24lm 6000-7000K Regular color temperature: warm white 2600-2900K,2900-3200K,3000-3500Knatural white 4000-4500K,4500-5000Kcool white 5000-5500K,5500-6000K,6500-7000Kcold white 7000-9000K,9000-15000KAvailable SMD type:3528, 2835, 5050, 5730, 3030Stable quality w0, 5730, 3030Stable quality with low optical attenuation1000h<1%, 3000h<3%, 10000h<8%A. Meet CE, FCC, RoHS, EMC,LVD certification;B. No RF interference, no buzzing noise and no UV radiation;C. Low power consumption, high intensity low lumen attenuation and wide range of available operating voltage; D. Easy to install and maintain,replacement of traditional bulbs;E. Environment-friendly, No hazard of mercury or lead entering the environment.F. High efficiency and energy-saving compared to conventional fluorescents which are equal bright, an

- Q:What does "1210" mean in patch LED?

- 1210 represents the size of the LED package specification (size, specification), and represents the length and width of the resistanceSpeed adoption!!!

- Q:How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- With double-sided adhesive, the temperature will not be very high. So it won't fall either. That's how I got it. It took me more than half a year, and I didn't have any problems

- Q:Notes on patch LED

- Storage bags are sealed and stored at a temperature of <40 DEG C.

- Q:What is patch LED?

- LED lights, a common model, has 34654635285050 piranha.The most common assembly of lights and PCB boards is the DIP, that is, dual in line and SMT surface mount technology two.The 346546 is the LED with two positive and negative pins, which are inserted into the PCB board after cutting the foot;3528 and 5050 are a cube with 3 LED lights inside, known as the "three in one" LED lamp. It has no pin underneath, but has a metal patch that can be passed through the reflow soldering machine through the solder to the PCB board.General indoor LED screen with more patches, outdoor screen with more pins.

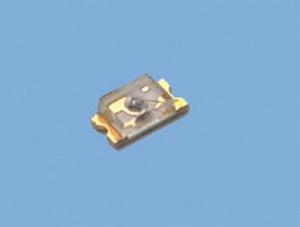

- Q:LED light SMD LED package in what form, trouble you under the guidance of...

- The LED chip has bumps and is welded to the PCB board using FLIP CHIP to packaging technology.LED is English light emitting diode (light emitting diode) abbreviation, its basic structure is a electroluminescent semiconductor chip light emitting materials, with silver glue or glue curing to the bracket, connecting a chip and a circuit board and then with silver or gold, then sealed with epoxy resin around, to protect the internal core role finally, the installation shell, so the seismic performance of LED lamp is good. Field of application involves mobile phones, desk lamps, household appliances and other daily household electrical appliances and machinery production.

- Q:LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Packaging is for TOP series LED, that is, the type of plastic molding. The patch is based on the PCB circuit board for molding. Mold release agent is used in molding.

- Q:Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- Generally small power LED rated current is basically 20mA

- Q:How do led patches measure good or bad?

- LED patch how to measure methods: use two meter meter test, red pen is positive, black pen negative, if there is "bee" sound is bad, if the light is good

- Q:LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- Of course, the reflow soldering is generally divided into three sections of six principle of oven temperature is 150 degrees, 190 degrees, 220 degrees, with a PC lens products can not reflow soldering, PC deformation at 150 degrees, can be heated by a soldering paste on the heating plate.

- Q:Led lamp and Led patch two what is the difference between ah, the feeling is a patch of long service life, whether or not? 5-10 meters pan area lighting lamp selection Everbright shaped or patch shape?

- If you take a large area light, to see that the lighting requirements, functional lighting, or lighting atmosphere, or ordinary lighting, which is to be considered, the two optical (lens) can bring you the light angle planning.

1. Manufacturer Overview |

|

|---|---|

| Location | Shenzhen,China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | Mid East;Western Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen |

| Export Percentage | |

| No.of Employees in Trade Department | 60 People |

| Language Spoken: | Chinese |

| b)Factory Information | |

| Factory Size: | Above 4,000 square meters |

| No. of Production Lines | About 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Cheap |

Send your message to us

LED SMD 5050 22-24lm 6000-7000K

- Loading Port:

- Shenzhen

- Payment Terms:

- TT

- Min Order Qty:

- 5000 Pcs pc

- Supply Capability:

- 10000000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords