Hot Sale Professional Manufacturer 0.1W 2835 SMD LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

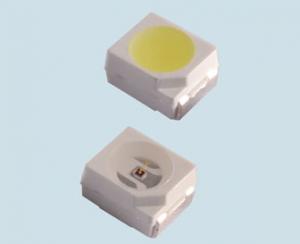

professional manufacturer 0.1w 2835 smd led

Specification

0.1w,2.8-3.4v,30mA,10-12m,5000-7000K( white)

SMD 2835 LED 0.1W

Color Temperature:

2900-3200K warm white

5000-7000K (500K tolerance,such as 5000-5500K) natural white

7000-9000K cool white

9000-15000K cool white

Applications

tube light, car light, strip light, panel light

Product Features

1. 3 years warranty

2. Superior raw materials

3.low power consumption, High intensity

4. Certification:CE, RoHs

5.Long lifespan: 50000+ hours, low light decay

6.Professional LED manufacturer for 8 years

Our Advantage

1.Over 8 years LED field history to offer professional service

2.Our engineer worked for Cree and Epistar who you can rely on.

3.TOP 50 LED manufacturer in China and TOP 10 LED manufacturer in Shenzhen.

4.All of our products has CE, ROHS and OEM/ ODM service are available

5.High quality chips from famous brand and strict inspection procedures

About us

we specialized in high power led,smd led,cob led,led driver.

For high power led ,include 1w,3w,5w,10-500w high power led,RGB led

For smd led ,include 2835,3528,5050,5730,3014,3030

Available Color: Red, Green, Blue, Yellow, Orange, White, RGB LED,Amber.

Red color other wavelength: 620nm,625nm,630nm,640nm,650nm,660nm,850nm

Good raw materials

Chip:USA Bridgelux chip, Taiwan Epistar ,Epileds,Genesis chip

Silicon glue: USA Dowcorning (good glue has less lighting decreasing)

Phosphor Powder: USA Intermatix (good powder has better performance in lumens)

Gold wire: Germany Herqeus 1.0mil Gold wire(for bearing bigger current, gold wire has less electricity resistance than silver and cooper)

Led base:red/ black cooper base (for better thermal conductive/ dissipation)

- Q:Notes on patch LED

- Moisture proof, in order to avoid the products in the transport and storage of moisture, SMD LED packaging is moisture-proof aluminum packaging, and packaging bag containing a desiccant and humidity card, mainly to control the desiccant bag, humidity, humidity card is mainly to monitor the packaging bag of humidity

- Q:Patch LED market conditions

- Patch LED (SMD LED) is mainly used in lighting systems, decoration, electronic equipment, indicators, backlight, monitors and instruments and other fields. The decline in handset and LCD TV production in 2009 could affect the supply expectations for such components.

- Q:What is the principle used in SMD LED lamp, should pay attention to what the problem?

- Pin forming, 1, LED pin molding must be completed before welding, bending angle must be more than 3mm of the gel to bend the stent. Pin over 2 times in the same place can not fold number, pin bent to 90 degrees, and then returned to the original position for 1 times; 2, pin forming must use fixture or by professional personnel to complete the first, pay attention to avoid the epoxy body caused by excessive internal wire fracture; 3, to ensure the distance between pin pin forming consistent with the circuit board; 4, when LED has good welding in the welding process or after, please don't bend light feet, to avoid damage to the lamp.

- Q:SMD LED lamp working voltage?

- Voltage range of white LED lamp: 3.0-3.4VThe pressure drop of the red LED is 2.0--2.2VThe yellow light emitting diode has a pressure drop of 1.8 - 2.0VThe green light emitting diode has a pressure drop of 3 - 3.2VThe blue light emitting diode has a pressure drop of 3.0-3.4VSMD voltage is basically the same as double lead line. Current is generally 20~60mA, and some work current can exceed 100mA.

- Q:How to detect LED SMD beads

- Resistance voltage ordinary pointer table 1.5V in general, and some only in the high resistance file (*10K file) with 9V or 15V battery, so the pointer table to measure LeD beads to hit the highest resistance profile measurement, otherwise useless, of course, at this time the brightness is very small, can not see, can only to judge the positive and negative resistance values see.

- Q:LED light SMD LED package in what form, trouble you under the guidance of...

- Draw your own line, mm is replaced by mil on the line, with vernier caliper measurement, or know the model, count the number of mil. For example, 5050 is a close square with a width of 5.0mm*5.0mmInline LED (such as straw hat lights, 5mm), piranha LED, surface mount LEDSinglechip collection from hardware to software chm

- Q:How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- You can also use the ohmmeter's ohmmeter. To dial multimeter, to "ohm X1" file, the light emitting diode when the red pen is connected to the positive terminal of SMD LED, the black probe is connected to the negative terminal of SMD LED.

- Q:How do led patches measure good or bad?

- The patch LED is also called SMD LED. Its principle of luminescence is to pass the current through the compound semiconductor. Through the combination of the electron and the hole, the excess energy will be released in the form of light to achieve the effect of luminescence.

- Q:LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- L electrode for eutectic solder reflow, the other can be used, regardless of the kind of welding, the temperature is not lower than 100 degrees, the flammable soluble materials have strict requirements, depending on whether the welding temperature is lower than the melting point of what you said or. Otherwise, there will be deformation or damage to the material in the reflow process.

- Q:What is patch SMD-LED?

- This really do not know how to answer you, like a sheet of the same type of solder paste used to operate, it can be said that the plug-in is not, it is patch it!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Sale Professional Manufacturer 0.1W 2835 SMD LED

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 500 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords