Geomembrane Systems

Geomembrane Systems Related Searches

Blu Ray Player With Internet Geomembrane In Pakistan 30 Mil Pvc Geomembrane Pvc Geomembrane Specifications Pvc Geomembrane Geomembrane Machine Plastic Geomembrane Nonwoven Wallpaper Geomembrane Material Geomembrane FabricHot Searches

Geomembrane For Sale China Pvc Geomembrane China Geomembrane Roll Sheet Hdpe Geomembrane Sheet Price Hdpe Geomembrane China China Geomembrane Geomembrane China Hdpe Geomembrane Price Geomembrane Price Wholesale Hdpe Geomembrane Roll Geomembrane Factory Wholesale Liner Hdpe Geomembrane Wholesale Geomembrane Hdpe Wholesale Hdpe Geomembrane Geomembrane Market Size Wholesale Hdpe Geomembrana Wholesale Liner Geomembrane Geomembrane Liner Supplier Wholesale Geomembrane China Pvc GeomembraneGeomembrane Systems Supplier & Manufacturer from China

Okorder.com is a professional Geomembrane Systems supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrane Systems firm in China.Hot Products

FAQ

- nan

- 1. To grind surface and use professional grinding machine polishing on the surface of the base, surface laitance, dust cleaning, open the original surface voids and make concrete seal curing agent could be fully penetrated 2, clean up the surface to be polished produced in the process of dust, the dust cleared off. 2. To clean up the surface: The dust produced in the process of polishing should be cleaned off. 3. To spray the concrete sealed curing agent and spray the concrete seal curing agent on the ground, and use the dust drag for uniform treatment. Let material response 2-4 hours. When the surface becomes sticky, you can go on the next step. 4. To clean the surface and water to flush the concrete seal curing agent material overflow part of the flushing reaction. To prevent the residue turn into white. 5. The water polishing. To polish the ground to further enhance the density of the ground surface, and show the mirror effect. 6. To clean the ponding, the remaining water should be cleaned after the water polishing. 7. The polishing of the concrete sealed curing agent, and install the resin polishing pad with the polishing machine, making a further polishing of the ground. 8. The completion display of the concrete seal curing agent .

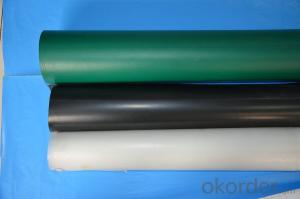

- The long-term performance characteristics of geomembranes include their ability to withstand environmental stressors such as UV radiation, temperature fluctuations, chemical exposure, and mechanical stress without significant degradation. They are also expected to maintain their impermeability, strength, and flexibility over time to ensure the integrity of containment and barrier systems. Regular inspections and maintenance can help prolong their lifespan and ensure their long-term performance.

- Yes, geomembranes are generally resistant to chemical solvents. They are designed to provide a barrier against various chemicals and solvents, making them an effective choice for containment applications where chemical resistance is required.

- nan

- the sound insulation can only be effective to the low-frequency noise, if the roadside has truck, bus or car horn whistle, I recommend installing the soundproof windows; if it is the kind of low frequency sound which is less than 50 db, then sticking the sound insulation film has a good effect.

- nan

- Principles of diaphragm pump: It is a displacement pump which casues volume change due to reciprocating deformation of mebrane. The working principle is similar to that of plunger pump. Due to the features of diaphragm pump working principle, it has the following characteristics: the pump does not overheat; it uses compressed air as power so it is in a process of expansion and heat absorption during exhausting air; the temperature of pneumatic pump in working is reducing without any harmful gas. no electric spark; becasue pneumatic diaphragm pump is not driven by electricity, it will not generate electrostatic spark after ground connection and liquid containing particles can also get through because the working type is volumetric and the entrance is ball valve, it is not easy to block. Flow can be adjusted. You can add a throttle valve at the outlet of the material to adjust the flow rate. with self-priming function. Dry run is ok and there is no danger. it can work under water. The fluid that can be transported is various, from low viscosity to high viscosity, and from the corrosive to the sticky. No complex control systems, no cables, fuses, etc. Small size, light weight, easy to move. It does not need lubrication so the maintenance is simple and will not pollute the work environment due to leakage. Pump can always remain efficient, even in wear. Adequate use of energy. The pump will shut down automaticly when the exit is closed. equipment movement, wear, overload, heat. Work without dead point. Pneumatic diaphragm pump is a new type of transport machine, and one of the most innovative domestic pump. Using compressed air as power, it can pump and absorb all kinds of corrosive liquid, liquid with particles, high viscosity, volatile, flammable, highly toxic liquid.

- nan

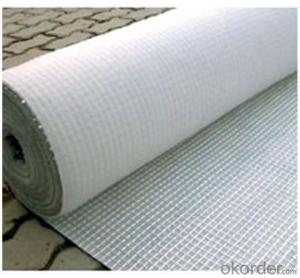

- The choice of composite geo-membrane norms and lower cushion?ply flatness, material allowable tensile stresses, material elastic modulus, the largest head within paving range and largest particle of covering layer. it's thickness design should consider hydraulic?pressure strength reqiurements, and the exposing, embeding, climate, service life and other application conditions, design thickness and actual thickness should be confirmed according to the issued relative standard.

- nan

- Electrothermal?film is very energy saving and comfortable.

- nan

- The paper cups are divided into single sided PE laminating dixie cup and two sides?PE?coated?paper cups single sided PE laminating dixie cup: the production of paper cups by single PE coated paper is called single PE dixie cup (common paper cup in the domestic market and advertising cup are mostly single sided PE laminating dixie cup), in the form of: the side of paper cup filled with water has a smooth PE lamination two sides?PE?coated?paper cups: the production of paper cups by double PE coated paper is called double PE paper cups, and in the forms: the inside and outside of paper cups have coated PE laminate.