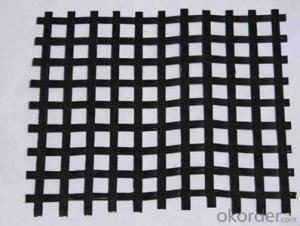

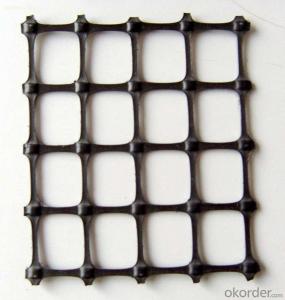

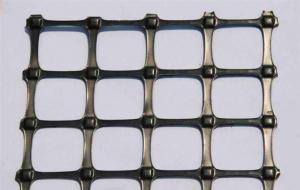

Geogrid Road

Geogrid Road Related Searches

Diamond Grinding Wheels For Steel Led For Cannabis Growing Plasticiser For Concrete Kst Values For Common Dusts Steel Concrete Molds Diamond Steel Roofing Stainless Steel Hole Saw Stainless Steel Sawzall Blade Cost Of Diamond Plate Aluminum 1/4 Inch Diamond Plate AluminumHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Buy Alabaster For Carving Geogrid China Geogrid Mesh Price Geogrid Fabric Price Geogrid Roll Price Geogrid Price List Tensar Triax 160 Geogrid Price Tensar Ss40 Geogrid Price Tensar Tx160 Geogrid Price Triax Geogrid Price Geogrid Price Tx160 Geogrid Price Fiberglass Scaffolding For SaleGeogrid Road Supplier & Manufacturer from China

Okorder.com is a professional Geogrid Road supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geogrid Road firm in China.Hot Products

FAQ

- Yes, fiberglass fabrics can be used for soundproofing. Fiberglass is a popular material for soundproofing due to its excellent acoustic properties. It effectively absorbs sound waves and reduces noise transmission, making it ideal for soundproofing applications. Fiberglass fabrics can be used in various forms, such as acoustic panels, curtains, or wall coverings, to reduce noise levels in residential, commercial, or industrial spaces. These fabrics are often used in recording studios, home theaters, offices, and other environments where sound control is necessary. The dense and porous structure of fiberglass facilitates the absorption and dissipation of sound energy, helping to create a quieter and more peaceful environment.

- There are several weaving patterns available for fiberglass fabric, including plain weave, twill weave, satin weave, leno weave, and basket weave. Each pattern offers different characteristics and properties, such as strength, flexibility, and breathability, allowing for various applications in industries such as aerospace, automotive, and construction.

- Yes, fiberglass fabrics can be used for insulation purposes. Fiberglass fabrics are made from extremely fine glass fibers that are woven together to form a flexible and lightweight material. This fabric has excellent insulation properties due to its ability to trap air and prevent the transfer of heat or cold. Fiberglass fabrics are commonly used in various insulation applications, including the insulation of pipes, ducts, walls, and roofs. They are also used in the manufacturing of thermal blankets and curtains for insulation purposes. Additionally, fiberglass fabrics can be used in combination with other insulating materials to enhance their overall effectiveness. One of the key advantages of using fiberglass fabrics for insulation is their high thermal resistance. They have a low thermal conductivity, which means that they can significantly reduce heat transfer and maintain stable temperatures in the insulated areas. Fiberglass fabrics are also non-combustible and have good resistance to moisture and chemicals, making them suitable for a wide range of insulation applications. Furthermore, fiberglass fabrics are easy to handle and install. They can be easily cut and shaped to fit specific dimensions, and they can be attached to surfaces using mechanical fasteners or adhesive. This flexibility and ease of installation make fiberglass fabrics a popular choice for both residential and commercial insulation projects. In summary, fiberglass fabrics are an excellent choice for insulation purposes. Their high thermal resistance, durability, and ease of installation make them a versatile and effective solution for various insulation applications.

- Yes, fiberglass fabrics are generally resistant to chemicals. Fiberglass is a composite material made of fine fibers of glass that are woven together to form a fabric. These fibers have excellent resistance to a wide range of chemicals, including acids, bases, solvents, and oils. This resistance makes fiberglass fabrics suitable for various applications where exposure to chemicals is common, such as in industrial equipment, chemical processing plants, and automotive parts. However, it is important to note that the level of chemical resistance may vary depending on the specific type of fiberglass fabric and the concentration and duration of exposure to the chemicals. Therefore, it is always advisable to consult the manufacturer or supplier for specific information regarding chemical compatibility and resistance of fiberglass fabrics.

- Fiberglass fabric performs well in high-temperature environments due to its excellent heat resistance properties. It can withstand temperatures up to 1000°F (540°C) without significantly degrading or melting. This makes it a suitable material for various applications such as insulation, fireproofing, and protective clothing in industries where high temperatures are present.

- Yes, fiberglass fabric can be used for gaskets. Fiberglass fabric is widely used in various industries, including automotive, aerospace, and manufacturing, due to its high strength, durability, and resistance to chemicals and extreme temperatures. These properties make it suitable for gaskets, which are used to prevent leaks or to provide a seal between two surfaces. Fiberglass fabric can be cut and shaped into the desired gasket size and can be further impregnated with adhesives or coatings to enhance its sealing capabilities. Additionally, fiberglass fabric is lightweight and flexible, allowing it to conform to irregular surfaces and provide a tight seal. Overall, fiberglass fabric is a versatile material that can effectively be used for gaskets in a wide range of applications.

- What does "PCB" mean?

- Mainly based on two reasons: one is the uniform copper foil can have very uniform temperature coefficient of resistance, low dielectric constant, which can make the signal transmission loss is smaller, and the capacitance of different capacitance requirements of high dielectric constant, so as to accommodate higher capacity in a finite volume, why is aluminum capacitor capacitance is smaller, after all is a high dielectric constant! Second, the thin copper foil through the high current temperature rise is small, which for heat dissipation and component life is very good, digital integrated circuit copper wire width is better than 0.3cm, this is also the truth. The finished product plate PCB well is very uniform, soft luster (because the brush on the surface of the solder resist), the naked eye can see, but honestly look at the copper coated base plate can be seen or not many people really, unless you are experienced in the factory inspection.

- Yes, fiberglass fabrics are generally resistant to solvents or cleaning agents. Fiberglass is a synthetic material made from fine fibers of glass, which provides it with excellent chemical resistance. It can withstand exposure to a wide range of solvents, cleaning agents, and chemicals without deteriorating or losing its structural integrity. This makes fiberglass fabrics an ideal choice for various applications where resistance to solvents or cleaning agents is required, such as in industrial settings, automotive components, insulation materials, and protective clothing. However, it is always recommended to check the specific chemical compatibility of the fiberglass fabric with the solvent or cleaning agent in question, as some highly aggressive chemicals may still have an impact on its performance.