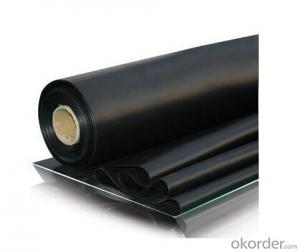

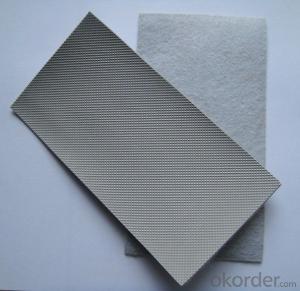

Firestone Epdm

Firestone Epdm Related Searches

Galvanized Steel Pool Intellibrite Led Pool Light Inground Pool Light Kits Waterproof Concrete Blocks Fiberglass Patio Roof Fiberglass Roof Philippines Shingles On A Roof Black Clay Roof Tiles House Roof Sheets Flat Roof Window InstallationHot Searches

Cost To Waterproof A Basement Waterproof Plywood Cost Waterproof Mdf Suppliers Grp Roofing Prices Geotextile Membrane Suppliers Breathable Roofing Felt Prices Roofing Tar Prices Bitumen Roofing Felt Suppliers Roofing Resin Suppliers Bituminous Waterproofing Membrane Manufacturers Waterproofing Company Names Outdoor Pool Bars For Sale Pool Chairs For Sale Pool Light Installation Cost Cost To Waterproof A Basement Synthetic Roof Tiles Cost Roof Clay Tiles Prices 30 Year Roof Shingles PricesFirestone Epdm Supplier & Manufacturer from China

Okorder.com is a professional Firestone Epdm supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Firestone Epdm firm in China.Hot Products

FAQ

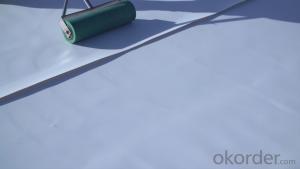

- Yes, a waterproofing membrane can be used for rooftop garden protection. Waterproofing membranes are designed to create a barrier against water penetration, preventing leaks and protecting the underlying structure. By installing a waterproofing membrane on the rooftop, it helps to protect the garden and prevent water damage to the building.

- Is the asphalt waterproofing membrane facing the side?

- Because there are many types of self-adhesive waterproofing membrane, their use and construction methods are different, there are two main methods. 1, the normal self-adhesive paving method: the film directly paving or polymer cement cement wetting method, paste in the grass-roots level. The bottom of the floor floor of the building, in the concrete cushion with cement mortar leveling, and then the coiled surface of the membrane down, paste in the leveling layer, the roll surface pouring 50 thick stone concrete protective layer, Floor concrete. Wall construction, the film directly attached to the basement wall panels, and then do the protective layer on the outside. Commonly used modified asphalt self-adhesive waterproofing membrane, modified asphalt wet sheet is usually used in this method.

- Cracks or joints in a surface can indeed have a waterproofing membrane applied over them. In fact, it is often advisable to do so to guarantee a thorough and efficient waterproofing system. The membrane serves as a barrier, preventing water from penetrating the cracks or joints and causing harm to the underlying structure. However, it is crucial to acknowledge that the cracks or joints must be adequately repaired and prepared prior to the application of the waterproofing membrane. This might entail cleaning, filling, and sealing the cracks or joints to ensure proper adherence of the membrane and the provision of a continuous and watertight seal. Moreover, the selection of the appropriate waterproofing membrane should be based on the specific requirements and conditions of the surface being treated.

- Below-grade parking structures may utilize a waterproofing membrane to prevent water infiltration and safeguard against water-related damage. This type of membrane is frequently employed in construction to create a barrier against water and its detrimental effects. Considering the nature of below-grade parking structures, which are either fully or partially underground, the surrounding soil and groundwater pose an increased risk of water seepage. To counteract this, waterproofing membranes are applied to the exterior surfaces of the structure. These membranes, typically composed of materials like bitumen, rubberized asphalt, PVC, or polyurethane, exhibit exceptional resistance to water penetration. Moreover, certain membranes may possess additional attributes such as crack-bridging capabilities or protection against chemicals or gases. For the optimal selection of a suitable membrane for a specific below-grade parking structure, it is vital to consult with an experienced engineer or waterproofing specialist. Factors such as soil conditions, hydrostatic pressure, and adherence to local building codes must be carefully considered in this decision-making process.

- Yes, a waterproofing membrane is designed to be resistant to extreme weather conditions. It provides a protective barrier against heavy rain, snow, and intense sunlight, ensuring that it remains intact and effective in preventing water infiltration and damage to the underlying structure.

- Yes, a waterproofing membrane can be used on precast stone surfaces. The membrane acts as a protective barrier, preventing water from penetrating the stone and causing damage. It is commonly used in construction projects to ensure the longevity and durability of precast stone surfaces.

- The optimal temperature range for applying a waterproofing membrane varies depending on the specific product. Generally, it is recommended to apply the membrane between 50°F and 90°F (10°C to 32°C). This temperature range ensures that the membrane bonds and cures effectively, resulting in effective waterproofing. Following the manufacturer's instructions is important, as they may provide more specific temperature recommendations based on their formulation and application process. It is also crucial to consider the ambient temperature and conditions during application, as extreme temperatures or weather conditions can impact the membrane's performance and effectiveness.

- Plant rooms and mechanical equipment areas can benefit from the use of a waterproofing membrane. It is necessary to waterproof these areas in order to safeguard the equipment and surrounding structures against water damage. A waterproofing membrane serves as a commonly implemented solution for this purpose. By forming a barrier, it effectively prevents water infiltration into the plant rooms and mechanical equipment areas, thereby ensuring the equipment remains dry and protected. Moreover, this membrane aids in averting moisture-related problems like the growth of mold and mildew, which can be detrimental to both the equipment's functionality and the overall operation of the plant room. Ultimately, incorporating a waterproofing membrane in plant rooms and mechanical equipment areas proves to be a dependable and efficacious approach for maintaining the longevity and performance of the equipment and structures.