EPDM Waterproof Membrane for Roofing Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

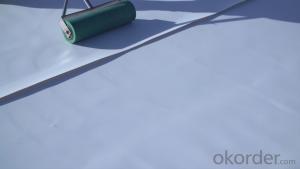

Description Of EPDM Waterproof Membrane for Roofing Market:

--EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is for waterproofing of exposed and non-exposed applications.

--EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

--EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

Main Features of EPDM Waterproof Membrane for Roofing Market:

--Excellent physical and mechanical performance

--High tearing resistance

--Good deformation adaptability

--High puncture resistance

--High aging resistance

--UV resistance

Application of EPDM Waterproof Membrane for Roofing Market:

--Roofs, Basement, Toilet

--Industrial and civil building waterproofing

--Geo-synthetic liner for swimming pool, channels, irrigation system

--Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Technical Parameters of EPDM Waterproof Membrane for Roofing Market:

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

2. What is your main market?

Our EPDM Waterproof Membrane for Roofing Industry sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

3. What is your advantage for EPDM Waterproof Membrane for Roofing Industry ?

With the most advanced production line, our good quality is based on superior material imported from America.

- Q:Are waterproofing membranes suitable for bridge abutments?

- Bridge abutments, the structures supporting the ends of a bridge, can benefit from the use of waterproofing membranes. Given their exposure to moisture and water, it is crucial to protect these structures. Waterproofing membranes serve as an effective barrier against water and moisture intrusion, making them an excellent solution for bridge abutments. These membranes, typically composed of materials like bitumen, PVC, or EPDM, possess high resistance to water penetration. Moreover, they offer additional protection against factors such as UV rays, chemicals, and temperature changes. By installing waterproofing membranes on bridge abutments, the risk of water damage, deterioration, and corrosion can be significantly reduced. Consequently, the bridge structure's durability and longevity are enhanced.

- Q:Can a waterproofing membrane be used for schools or universities?

- Yes, a waterproofing membrane can definitely be used for schools or universities. Waterproofing membranes are commonly used in various construction projects, including educational institutions, to protect the building from water damage. These membranes are applied to the exterior surfaces of the structure, such as roofs, walls, or foundations, to create a barrier that prevents water infiltration. By implementing a waterproofing membrane, schools and universities can ensure that their buildings remain dry and free from water-related issues such as leaks, mold growth, or structural damage. This not only helps to maintain the integrity and longevity of the building but also provides a safe and comfortable environment for students, staff, and visitors. Additionally, waterproofing membranes can also be used in areas such as bathrooms or wet laboratories to prevent water seepage, which is especially important in educational settings where high traffic and frequent use of water are common. Overall, using a waterproofing membrane in schools or universities is a proactive measure to protect the infrastructure, enhance durability, and promote a conducive learning environment.

- Q:Is a waterproofing membrane resistant to algae or moss growth?

- Yes, a waterproofing membrane is typically resistant to algae or moss growth. Waterproofing membranes are designed to create a barrier against water infiltration, preventing moisture from seeping into the underlying structure. These membranes are typically made of materials that are not conducive to the growth of algae or moss, such as synthetic polymers or rubberized compounds. Additionally, waterproofing membranes are often treated with additives that inhibit the growth of organic matter, including algae or moss. However, it is important to note that over time, if the membrane is exposed to constant moisture or damp conditions, it may become a breeding ground for algae or moss. Therefore, regular maintenance and cleaning are important to ensure the longevity and effectiveness of the waterproofing membrane.

- Q:Can a waterproofing membrane be used for water treatment plants?

- Yes, a waterproofing membrane can be used for water treatment plants. Waterproofing membranes are designed to prevent the passage of water and can be used to provide a barrier against water leakage in various structures, including water treatment plants. These membranes can be applied to different areas of the plant, such as tanks, reservoirs, pipes, and basements, to prevent water infiltration and protect the infrastructure from potential damage. Additionally, waterproofing membranes can help maintain the integrity of the water treatment process by ensuring that water remains contained within designated areas and does not seep into surrounding soil or structures.

- Q:Does a waterproofing membrane require any specific curing time before it can be exposed to water?

- Before being exposed to water, a waterproofing membrane typically needs a specific amount of time to cure. This curing period is necessary for the membrane to fully bond and create a protective barrier against water infiltration. The length of time required may vary depending on the type of membrane and the instructions provided by the manufacturer. To guarantee the effectiveness and durability of the membrane, it is crucial to adhere to the recommended curing time. Premature exposure to water before the curing process is finished could compromise the membrane's performance, resulting in leaks or damage. Therefore, it is essential to follow the manufacturer's guidelines and allow the necessary curing time before subjecting the waterproofing membrane to water.

- Q:Can a waterproofing membrane be used for bridges?

- Yes, a waterproofing membrane can be used for bridges. Bridges are exposed to harsh weather conditions and constant exposure to water, which can lead to deterioration and structural damage. Applying a waterproofing membrane to the bridge surface helps to protect it from water infiltration, preventing corrosion of reinforcing steel and extending the lifespan of the bridge. The membrane acts as a barrier, preventing water from seeping into the concrete and causing structural damage. It also helps to minimize the effect of freeze-thaw cycles, which can further damage the bridge. Additionally, the waterproofing membrane can improve the overall durability and performance of the bridge, reducing maintenance and repair costs in the long run.

- Q:Can a waterproofing membrane be used for parking garages?

- Yes, a waterproofing membrane can be used for parking garages. Waterproofing membranes are commonly used in construction to prevent water infiltration and damage to structures. Given the potential exposure of parking garages to water from rainfall, snowmelt, or vehicle fluids, using a waterproofing membrane can help protect the structural integrity of the garage and extend its lifespan.

- Q:Can a waterproofing membrane be used for a crawl space?

- Indeed, a crawl space can benefit from the application of a waterproofing membrane. Given their vulnerability to moisture and water infiltration, crawl spaces can experience a range of problems including the growth of mold, structural deterioration, and unpleasant odors. By employing a waterproofing membrane, the infiltration of water and moisture into the crawl space can be effectively impeded. Typically, this membrane is affixed to the walls and floors of the crawl space, forming a secure seal that prevents any water from seeping through. Consequently, this membrane serves as an exceptional remedy for the waterproofing of crawl spaces. Furthermore, certain waterproofing membranes possess antimicrobial properties, thereby further diminishing the likelihood of mold and mildew growth within the crawl space.

- Q:Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to consider a few factors when applying these membranes in low temperatures. Cold weather can affect the curing process of the membrane, potentially slowing it down. It is crucial to ensure that the surface being waterproofed is dry and free from ice or frost before applying the membrane. Additionally, some waterproofing products may have specific temperature requirements for optimal performance, so it is essential to consult the manufacturer's guidelines. In colder temperatures, it may also be necessary to use specialized adhesives or primers designed for cold weather applications. Overall, with proper precautions and the use of appropriate materials, waterproofing membranes can be successfully applied in cold weather.

- Q:Can a waterproofing membrane be used for balconies or terraces?

- Yes, a waterproofing membrane can be used for balconies or terraces. This membrane is specifically designed to prevent water penetration and protect the underlying structure from moisture damage. It creates a barrier that keeps water out, ensuring the longevity and durability of balconies and terraces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EPDM Waterproof Membrane for Roofing Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords