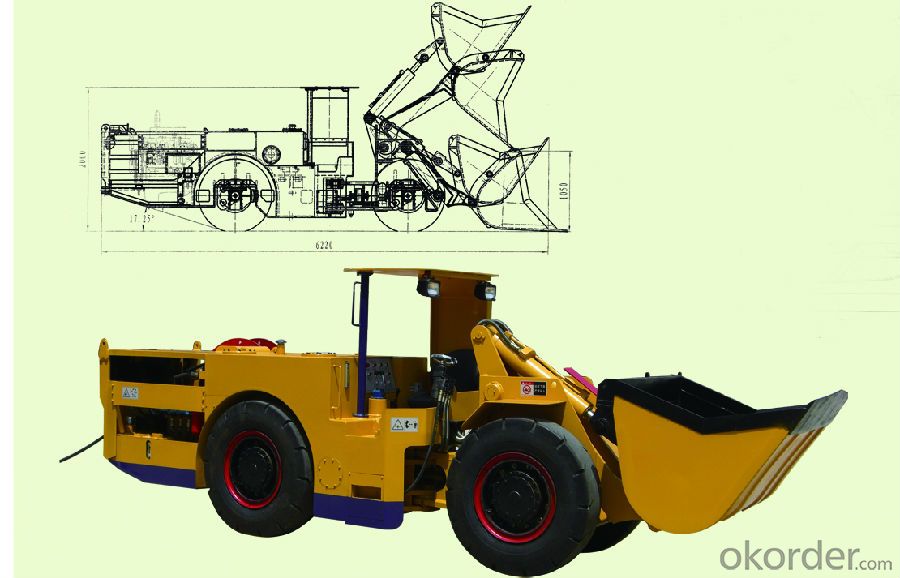

XDCY-1D 1m3 Electric Scooptram 2.0ton Loader

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 500 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

A loader (bucket loader, front loader, front-end loader, payloader, scoop, shovel, skip loader, or wheel loader) is a heavy equipment machine used in construction to move aside or load materials such as asphalt, demolition debris, dirt, snow, feed, gravel, logs, raw minerals, recycled material, rock, sand, woodchips, etc. into or onto another type of machinery (such as a dump truck, conveyor belt, feed-hopper, or railroad car).

Main Product Features:

● powered by 380V / three-phase asynchronous motor, no air pollution, noise, low temperature, environmentally friendly design.

● travel system used by the U.S. SAUER variable piston pump and variable piston motor, hydraulic operation, making operation more agile driving scrapers, effectively reducing the failure rate, improve work efficiency.

● Operating system adopts pilot control, making the operation more easily, work more efficiently.

● Volume cable system uses hydraulic control, retractable cable smooth and stable, the user can use according to their own set pressure, to protect the cable, extension cable life.

● the use of technologically advanced swing slewing structure, compared to the traditional form of the rear axle swing, lower failure rate, easy to maintain.

● wet brakes, hydraulic brake release or shutdown immediate, safe and reliable.

● vehicle chassis plate thickening, enhanced vehicle steel bucket shovel blade made of high strength alloy steel, wear resistance to shear, V-type structure, reducing scooping resistance and longer life.

● Adopt 10.00-20 puncture resistant smooth rubber tires.

● The machine can be shoveling, loading, transport, unloading one operation, compact structure, convenient operation, high efficiency operation for recovery of mines and tunneling mucking, and workplace and road construction formation, transport of materials and other auxiliary operations.

Product Specifications:

Model | |

Bucket capacity (m3 ) | 1.0 |

Rated load (t) | 2.0 |

Weight (t) | 7.2 |

Min turning radius (outside) (mm) | 4260 |

Min turning radius(innerside) (mm) | 2540 |

Traveling speed (km/h) | 0-8 |

Grade ability | 20 |

Overall length (mm) | 6090 |

Overall width(mm) | 1380 |

Overall height(mm) | 2000 |

Wheel base (mm) | 2200 |

Max. dumping height(mm) | 1160 |

Dumping reach (mm) | 860 |

Engine model | Y225-4 |

Rated power(kw) | 45 |

Tire type | 10.00-20 |

FAQ:

Q1: Can the bucket can be replaced with other devices or tools?

A1: Yes, The bucket can be replaced with other devices or tools—for example, forks to lift heavy pallets or shipping containers, and sometimes a hydraulically opening "clamshell" bucket to act as a light dozer or scraper. The bucket can also be augmented with devices like a bale grappler for handling large bales of hay or straw.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Wheel Loader according to customers request?

A4: Yes, we can produce Wheel Loader according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Loader is a widely used construction machine earthwork roads, railways, construction, utilities, ports, mines and other construction projects, it is mainly used for loading shovel of soil, sand, lime, coal and other bulk materials, can also be ore , hard soil, etc. for mild shoveling job. Dress different auxiliary work but also for earth-moving equipment, lifting and other materials such as timber loading and unloading operations. In the road, especially in highway construction, the loader for subgrade excavation and filling, asphalt and cement concrete aggregate stockyard and loading and other operations. But it can also be pushing soil, ground and evenness other mechanical traction and other operations. Since the loader has the operating speed, high efficiency, good mobility, easy operation, etc., so it becomes one of the major aircraft construction earthwork constructio.

- Q:Likes dislikes...what is your opinion

- absolutely loving the smooth top. Have the GE with the expandable ring so that it takes the huge soup pots for family meals. Front loader is awesome!!!!!

- Q:I am looking to buy a flintlock muzzle loader to use for deer. however, i know nothing about flintlock muzzle loaders, from what good brands to consider, to cleaning and maintenance and components. please tell me whatever you can about them or direct me to a site with some information about them. what are some good brands? what kind of rounds to they shoot? how hard is it to clean them? two of my family members hunt with flintlocks but i just haven't had the chance to ask them yetthanks in advance for your answers

- I okorder / and view their black powder rifle section. Cabelas carries several from Traditions and Uberti and they are quality rifles. One other thing: don't let the naysayers scare you away--flintlocks are a lot of fun. A properly loaded pan will fire every time just like a percussion or in-line will.

- Q:I have a USB Loader GX for my wii and it was working fine till recently when I updated my Wii to 4.3...Now everytime we click on it from the Wii menu all we see is a black screen and it doesnt load to my games.How do i fix this issue???

- All you had to do was create a WBFS folder and put the WBFS games in it, also the flash drive should be in USB port 0

- Q:recently while trying to load new backups, it only showed black screen or blue screens which says errors so i tried changing the IOS and accidentally changed it to IOS 256 instead of changing it back to 249. Now Softchip Loader doesn't even load it always gives me a black screen when i start it.Wii information:(I had everything payed for at a shop so I'm not familiar with the settings of the wii)modchip installedthe homebrew channel installedi think it was 3.3J but it is now 3.2Uif you need to know anything else just ask I'll write it again at the additional details

- For the best answers, search on this site https://shorturl.im/ax8Q7 Been there. Done that. I hope that makes you feel better! :-) Well sister, you know premarital relationships are Haram. And I know that you are a very sweet, responsible individual. When you go to high school, college, university you will face these issues because it is unavoidable. As a Muslim woman, you are required to marry a Muslim man only. I am sorry if this sounds harsh, but you have to avoid being around this guy whom you like. Let me tell you one thing, crushes come and go. Lust comes and goes. You need to realise that you haven’t found true love yet. Remember, Allah (Swt) has brought us down in pairs. Surely He has matched you with a Muslim man? As for salat, you need to set the alarm and wake up for Fajr! Do wudu’, gulp in some fresh air and pray. Pray to Allah (Swt) for forgiveness, happiness, ecstasy, etc. Allah (Swt) is All Merciful. He does not place any difficulty on you that you cannot tolerate. Keep faith in Allah (Swt). Music surrounds us everywhere we go. There is nothing wrong with listening to music, unless it contains lyrics which can have a big impact on you (e/g depending on music to calm you down when you can read the Quran) - in other words, you can listen to music as long as it doesn’t distract you away from reciting the Quran. If you want to simply cut down listening music, then listen to Nasheeds or Quran recitations. Peace and God bless.

- Q:I try to play some of the games but end up being brought back to the Wii menu. Others just come to a black screen and stay like that. Any Ideas?

- I'd okorder / If you get black screens from either of those it could be a bad rip, try replacing it on your wbfs. It could also be an cIOS issue, you could try updating them. Hope this solves your problem, Good luck to you!

- Q:i need to get isi loader but i searched everywhere can you tell me some links and also i cant get isi dragonfa

- can you be more specific. first are you using windows or Linux ? in Windows there is no such thing as isi loader there is something called ntldr loader or boot.ini file. in lunix there is lilo boot loader. or is it a driver you are looking for ?

- Q:its under the alternator and to the right of the starter. it has a dipstick like your supposed to fill it with some kind of fluid.....I don't know what it is???????I have never owned a commercial backhoe and cant find anyone to help me...it is a 480c case backhoe front loader construction king.if u need a picture of it u can email me and I can sent it to you.

- that is your power steering reservoir. it requires standard hydraulic oil. your hydraulic reservoir should be built into the loader frame in one of the uprights

- Q:Please help me, I'm currently backing up my original Wii Sports disk to a 32GB thumb drive and it's taking over an hour! I heard somewhere that it should take just over 5 minutes. Anyone? I'm using CIOS 10 and USB Loader 1.5

- i recommend you use your computer and transfer over the iso's or revert back to cios rev 9 and usb loader 1.1 (the most stable version)

- Q:I already have usb loader gx installed on my wii. I now want to use some cheat codes for games like mariokart and super smash bros brawl. I dont know how to do any of this and would appreciate a detailed walkthrough of what to do... and my usb loader gx does allow ocarina. So thanks :)

- i use the same usb loader gx. go to ocarina an enable it then mine opens a box so i can enable what codes i want (must be connected to internet so it can find cheats)

- Q:I have an airsoft Baretta FS92 Pistol, and I was wondering if I should get this and if it would work??? Its very hard and takes a while to reload this gun. Would this be good?

- its just a little plastic thing that u put your bb's into like a hi-cap but u push the tip onto a midcap or a standard mag and push the handel down, its called a speed loader cuz it loads your mag much faster than thumb loading 30 rounds into your standard mag or a 150 into a mid cap

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

XDCY-1D 1m3 Electric Scooptram 2.0ton Loader

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 500 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords