Tile-on Roof Solar Mounting System VRTD Product

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Widely used for both crystalline and thin film modules.

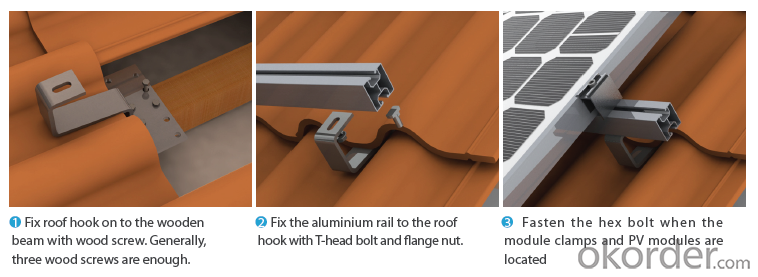

Easy & quick installation.

Only 4~5 kinds of components and no more than three kinds of tools in whole system fixation.

All system components are made with high quality aluminum & stainless steel.

Technical Data

Installation site | Sloped roof tile |

Module specification | Frame / frameless module |

Installation inclination | Client requirement |

Module arrangement | Portrait |

Module area square | Client arrangement |

Module area position | Client arrangement |

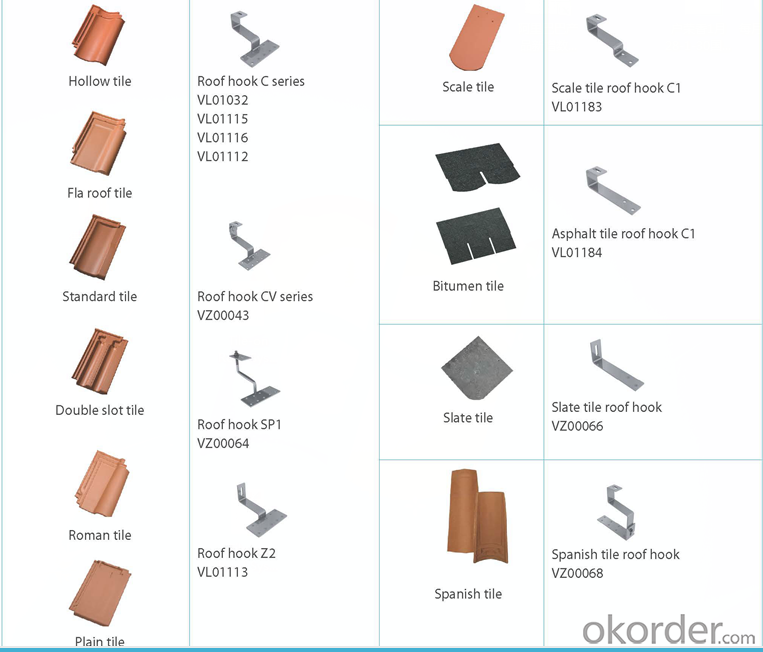

Roof hook | stainless steel |

Small pieces | Stainless steel, Al6063 T5 |

FAQ

I..Will you focus on the safety of the goods during transportation?

Yes, Safety of the cargo is the primary element that we would consider on transportation.

II..How would guarantee the quality will meet the requirements of your clients?

Before shipment, we will have inspection for each batch of goods.

III..What certificates do you have?

IEC,UL,TUV,CSA,etc.

IV..Can you do OEM according to clients’ requirements?

Yes, we have our own brand while we can provide OEM service.

- Q:Are there any specific requirements for installing a solar mounting system on a green roof?

- Yes, there are specific requirements for installing a solar mounting system on a green roof. These requirements typically include ensuring that the roof structure can support the additional weight of the solar panels and mounting system, evaluating the roof's drainage capabilities to prevent water leakage, and selecting appropriate mounting brackets that are compatible with the green roof system. It is also important to consider the orientation and tilt of the solar panels to maximize their energy production. Additionally, proper waterproofing and sealing measures must be taken to protect the roof from potential damage.

- Q:What is the warranty on a solar mounting system?

- The warranty on a solar mounting system can vary depending on the manufacturer and the specific product. However, most reputable companies offer warranties ranging from 10 to 25 years, ensuring that the system is free from defects and will perform as expected during that period.

- Q:Are there any specific requirements for buoyancy when using a solar mounting system for floating solar?

- Yes, there are specific requirements for buoyancy when using a solar mounting system for floating solar. The mounting system needs to be designed in a way that it provides sufficient buoyancy to support the weight of the solar panels and other associated equipment, while also ensuring stability and preventing any tilting or sinking. Additionally, the buoyancy requirements may vary depending on factors such as the size and weight of the solar panels, water conditions, and the specific location of the floating solar installation.

- Q:Can a solar mounting system be used in areas with limited access to feed-in tariffs?

- Yes, a solar mounting system can still be used in areas with limited access to feed-in tariffs. While feed-in tariffs provide financial incentives for generating excess solar power and selling it back to the grid, a solar mounting system can still be beneficial for self-consumption of solar energy. By installing solar panels, individuals and businesses can reduce their reliance on grid electricity and save on their energy bills, even without receiving feed-in tariff payments. Additionally, some regions may have other incentives or programs in place to promote solar energy adoption and compensate for the lack of feed-in tariffs.

- Q:Can a solar mounting system be used in areas with solar incentives for parking lots?

- Yes, a solar mounting system can indeed be used in areas with solar incentives for parking lots. In fact, utilizing a solar mounting system in parking lots can be a smart and sustainable way to take advantage of solar incentives while also providing shaded parking spaces and reducing the environmental impact of traditional energy sources.

- Q:Can a solar mounting system be used in areas with solar incentives for gyms?

- Yes, a solar mounting system can be used in areas with solar incentives for gyms. These incentives are designed to encourage the adoption of renewable energy systems, including solar power. By installing a solar mounting system, gyms can take advantage of these incentives and potentially reduce their energy costs while promoting sustainability.

- Q:Can solar mounting systems be installed on rooftops with lightning protection systems?

- Yes, solar mounting systems can be installed on rooftops with lightning protection systems. In fact, it is recommended to integrate solar installations with existing lightning protection systems to ensure the safety of the solar panels and the building. This helps to divert any lightning strikes away from the solar panels and prevent potential damage.

- Q:Can a solar mounting system be installed on a government or municipal building?

- Yes, a solar mounting system can be installed on a government or municipal building. Many government and municipal buildings across the world have already installed solar panels as part of their efforts to reduce carbon emissions and transition to renewable energy sources. These buildings provide ample roof space for solar panel installations, making them ideal candidates for solar mounting systems. Additionally, government and municipal buildings often have the resources and support necessary to undertake such projects, further facilitating the installation process.

- Q:Can a solar mounting system be used for ground-mounted solar farms?

- Yes, a solar mounting system can be used for ground-mounted solar farms. Ground-mounted solar farms typically use fixed-tilt or single-axis tracking systems to support and position solar panels at an optimal angle to maximize energy production. These mounting systems are designed to securely hold the panels in place and withstand various weather conditions, making them suitable for large-scale solar installations on the ground.

- Q:How does a solar mounting system affect the building's structural integrity?

- A solar mounting system can have a minimal impact on a building's structural integrity if it is properly designed and installed. The added weight of the solar panels and the forces they exert on the building's structure need to be carefully considered to ensure that the building can withstand the additional load. By using appropriate mounting techniques and distributing the weight evenly, the structural integrity of the building can be preserved while harnessing the benefits of solar energy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tile-on Roof Solar Mounting System VRTD Product

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords