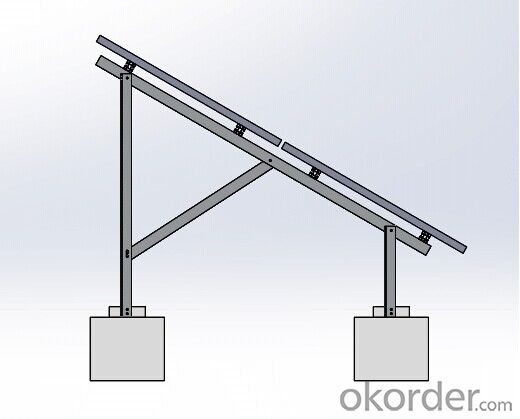

Solar Mounting System with Embedded Concrete Iron Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Solar Mounting System with Embedded Concrete Iron Plate

Feature for solar mounting system with embedded concrete ironplate.it can apply to complex terrain conditions,with front and back column canbe cutting,welding and leveling of array in construction site.make suresupporting and base structure are entirety with firm,reliable,stabilized andgood safety performance.secondary protection are needed in construction site,inorder to shorten the age of anticorrosion.

Product Description:

40 years of experience in steel and aluminium and in light metal construction design and light metal structures.

Over 15 years of expertise in Solar Mounting Systems!

Schletter is the biggest supplier of solar mounting systems in Europe with more than 1200 employees worldwide.

Experience from over 6 GW of mounted systems Your professionals for planning, advice and production!

Specification:

| Installation site | Outdoor ground |

| Installation angle | customization |

| Wind resistance | 35m/s |

| Solar Panel Type | frame or frameless |

| Solar panel size | any size |

| Mount track | aluminum extrusion attachment |

| Mount materials | Q235B |

| Installation height | customization |

| Snow load | 1.4KN/m2 |

| Components arrangement | laterally or longitudinally |

| International Standards | comply with AS/NZS 1170 and other international standards |

| Quality Warranty | 20 years |

FAQ:

1. How long will my inquiry get response?

Your inquiry related to our products or prices will be replied within 24 hours.

2. Can I get professional service and suggestion?

Well-trained and experienced staffs to answer all your questions in fluent English.

3. Do you accept OEM or customized design?

OEM & ODM, any your customized lightings we can help you to design and put into product.

4. What if I need specific design?

Distributorship are offered for your unique design and so me our current models.

- Q:Can a solar mounting system be used in earthquake-prone areas?

- Yes, a solar mounting system can be used in earthquake-prone areas. However, it is crucial to ensure that the mounting system is designed and engineered to withstand seismic activities. Specialized mounting structures and installation techniques can be employed to enhance the system's resilience and minimize the risk of damage during earthquakes.

- Q:How does a solar mounting system affect the roof's waterproofing?

- A solar mounting system can affect the roof's waterproofing by penetrating the surface with bolts or brackets used to secure the panels in place. These penetrations can potentially create areas where water can seep through and compromise the roof's integrity. However, when installed correctly with proper waterproofing measures, such as flashing and sealants, the impact on waterproofing can be mitigated, ensuring the roof remains watertight.

- Q:Are there any specific requirements for bifacial panel placement when using a solar mounting system?

- Yes, there are specific requirements for bifacial panel placement when using a solar mounting system. Bifacial panels are designed to capture sunlight from both sides, so they need to be mounted in a way that allows light to reach the rear side of the panels. This can be achieved by using a mounting system that elevates the panels off the ground, allowing light to reflect onto the rear side. Additionally, the mounting system should be designed to minimize shading and maximize the exposure of the rear side of the panels to sunlight.

- Q:What is the expected reduction in carbon emissions with a solar mounting system installation?

- The expected reduction in carbon emissions with a solar mounting system installation depends on several factors, including the size of the solar system, the location, and the energy consumption of the property. However, on average, a solar mounting system can reduce carbon emissions by around 2 to 4 tons per year for a typical residential installation.

- Q:Can a solar mounting system be used with solar battery storage systems?

- Yes, a solar mounting system can be used with solar battery storage systems. The mounting system is designed to securely hold the solar panels in place, regardless of whether they are connected to the grid or a battery storage system.

- Q:Can a solar mounting system be used for solar-powered pumps or irrigation systems?

- Yes, a solar mounting system can be used for solar-powered pumps or irrigation systems. Solar mounting systems provide a secure and stable platform to install solar panels, which can generate the needed electricity to power pumps or irrigation systems. This allows for a sustainable and environmentally friendly solution for powering these systems.

- Q:What is the expected increase in resell value with a solar mounting system?

- The expected increase in resell value with a solar mounting system can vary depending on various factors such as the size and efficiency of the system, the location and demand for solar energy, as well as the overall condition and age of the property. However, studies suggest that homes equipped with solar panels tend to have a higher resale value compared to those without. On average, homeowners may expect an increase in resell value of around 4-5% with a solar mounting system.

- Q:Can a solar mounting system be used with concentrated solar power (CSP) systems?

- Yes, a solar mounting system can be used with concentrated solar power (CSP) systems. CSP systems use mirrors or lenses to concentrate sunlight onto a receiver, which then converts the solar energy into heat or electricity. These concentrated solar power systems require precise tracking and alignment to maximize efficiency, and a solar mounting system can provide the necessary support and adjustability for the CSP components.

- Q:Can a solar mounting system be used in areas with limited access to solar forums?

- Yes, a solar mounting system can be used in areas with limited access to solar forums. While solar forums can provide valuable information and resources for designing and installing solar systems, the basic principles of solar mounting systems can be understood and implemented without relying solely on forums. Consulting with local solar installers, researching online resources, and seeking guidance from manufacturers can also be effective in adapting solar mounting systems to areas with limited access to forums.

- Q:Can solar mounting systems be installed on asphalt roofs?

- Yes, solar mounting systems can be installed on asphalt roofs. Asphalt roofs are commonly used and can support the weight and installation requirements of solar mounting systems. However, it is important to consult with a professional installer to assess the roof's condition and ensure proper installation techniques are followed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Solar Mounting System with Embedded Concrete Iron Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords