Percussive Drilling Pile Mounting System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10watts watt

- Supply Capability:

- 1-1000000watts/month watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of the Percussive Drilling Pile Mounting System

Packaging Detail: wood case, wood pallet ,carton

Delivery Detail: 10- 15 working days

Specifications of the Percussive Drilling Pile Mounting System

Solar ground mounting system:

1.Easy installation

2.High durability

3.Standup to extreme weather

4.long Warrenty

Product description of the Percussive Drilling Pile Mounting System

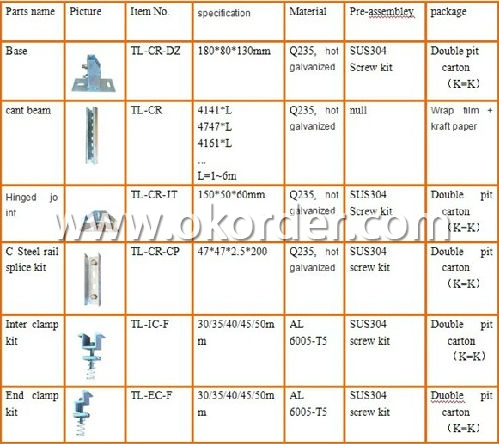

Ground mounting structure which is applicable to construct photovoltaic power mounting with high anticorrosive performance. The mounting system Using the edge stress C steel as main body and integrates with spare parts, such as C steel splice kit and spring module etc…For the convenience of customers, we are ready for all kinds of specifications C steel, such as 41*41*2.0mm, 47*47*2.5mm, 41*61*2.5mm etc…Of course, we can also be customized according to All mounting accessories is pre-installed SUS 304 screws before shipment to minimize the time and cost of installation.

The details of the Percussive Drilling Pile Mounting System

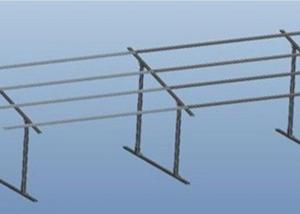

The show of the Percussive Drilling Pile Mounting System

The package of the Percussive Drilling Pile Mounting System

- Q:Are there any specific requirements for flashing when using a solar mounting system on a sloped roof?

- Yes, there are specific requirements for flashing when using a solar mounting system on a sloped roof. Flashing is essential to ensure proper waterproofing and to prevent any leaks. The flashing should be installed around the mounting brackets and penetrations, such as where the panels are attached to the roof, to create a watertight seal. It is important to follow the manufacturer's guidelines and local building codes when selecting and installing the appropriate flashing materials for the specific type of roof and solar mounting system being used.

- Q:Can a solar mounting system be used in areas with high winds?

- Yes, a solar mounting system can be used in areas with high winds. However, it is crucial to ensure that the mounting system is designed and engineered to withstand the specific wind conditions in the area. This may involve using appropriate anchoring techniques, robust materials, and reinforced structures to ensure the stability and safety of the solar panels in high winds.

- Q:Can a solar mounting system be used with different types of solar panels?

- Yes, a solar mounting system can be used with different types of solar panels. Most solar mounting systems are designed to be versatile and compatible with various panel sizes and configurations, allowing for easy installation and integration regardless of the specific type of solar panels being used.

- Q:How much weight can a roof-mounted solar system support?

- The weight capacity of a roof-mounted solar system depends on various factors such as the type of roof, structural integrity, and the specific design of the solar system. It is crucial to consult with a professional solar installer or structural engineer to determine the exact weight limit that your roof can safely support.

- Q:Are there any specific requirements for pergola or shade structure design when using a solar mounting system?

- Yes, there are specific requirements for pergola or shade structure design when using a solar mounting system. These requirements primarily include ensuring structural integrity and stability to support the weight of the solar panels. Additionally, the design should allow for proper airflow around the panels to prevent overheating. It is also important to consider the orientation and tilt angle of the panels for optimal solar energy production.

- Q:What is the expected payback period for a solar mounting system?

- The expected payback period for a solar mounting system can vary depending on factors such as the initial cost of the system, the amount of energy it generates, the local electricity rates, and any available incentives or tax credits. However, on average, it typically ranges from 5 to 10 years.

- Q:Can a solar mounting system be used with solar battery storage systems?

- Yes, a solar mounting system can be used with solar battery storage systems. The solar mounting system is responsible for securely fixing the solar panels to a surface, while the battery storage system stores excess energy produced by the panels for later use. These two components work together to create an efficient and sustainable solar energy system.

- Q:What is a finished stent?

- and drainage works, construction electrical engineering, building HVAC projects, solar photovoltaic systems, subway support system and other systems, and so forth.

- Q:Can a solar mounting system be used for solar water heaters or thermal systems?

- Yes, a solar mounting system can be used for solar water heaters or thermal systems. The mounting system provides a secure and stable platform for positioning solar panels or thermal collectors to capture solar energy efficiently. This helps in maximizing the performance and effectiveness of solar water heaters or thermal systems.

- Q:Can a solar mounting system be used in areas with extreme temperatures?

- Yes, solar mounting systems can be used in areas with extreme temperatures. However, it is crucial to choose a mounting system specifically designed to withstand the particular climatic conditions of the area. High-quality solar mounting systems are built with durable materials and coatings that can withstand extreme heat, cold, and other harsh weather conditions. Additionally, proper installation techniques and regular maintenance are essential to ensure the longevity and performance of the solar mounting system in such environments.

1. Manufacturer Overview |

|

|---|---|

| Location | Ningbo,China |

| Year Established | 2001 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East;Western Europe;North America |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 200 |

| Language Spoken: | English;Chinese;Japanese |

| b)Factory Information | |

| Factory Size: | Above 3,600 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Percussive Drilling Pile Mounting System

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10watts watt

- Supply Capability:

- 1-1000000watts/month watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords