Triangle Single Set Sloped Axis Tracking System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

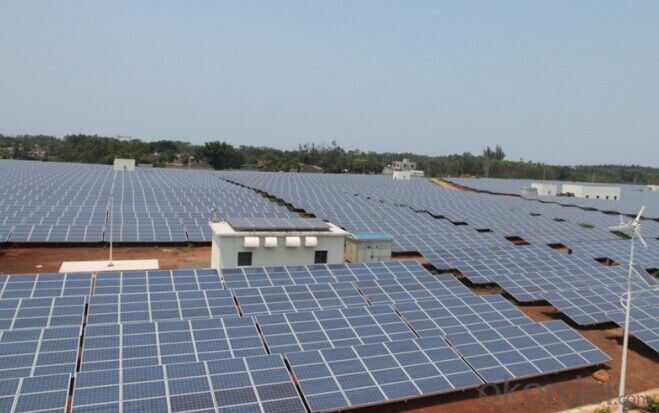

Triangle Single Set Sloped Axis Tracking System

triangle single set sloped axis tracking system is adopt triangle bracket support and frame Structure,high weight and easy installation(free hoisting construction and low requirement on foundation),low power consumption and high reliability.moving parts used polymer bearings with self-lubrication and slewing drive with sealing,free of oil and maintenance free and self-protection from wind and sand.power generating can be increased by 20-35%.

Features:

1. The system, which uses an isosceles triangle bracket as bracket structure and maintenance-free, wind and sand-proof high polymer material bearing moving parts and unique linkage structure, features reliable system stability, low cost and low failure rates.

2. Compared with traditional fixed-bracket its annual energy output can be increased up to approximately 20 percent - 30 percent.

3. With exactly the same or even lower cost as fixed-bracket the system is the optimal choice for the establishment of large and medium-sized high-efficiency solar power stations.

Specificiation:

•installed capacity | • 1KW—10KW |

•control method | •Light control •time control •light/time control |

•tracking accurancy | • ≤1° |

•Azimuth angle | • ±45° |

•working wind | • 50—70km/h |

•Max wind resistance | • 125—200km/h |

•Driven power | • DC24V/≤30W |

•Structural material | • Q 2 3 5 hot-dip galvanized steel |

•level of protection | • I P 6 5 |

•Quality guarantee | • 25Y/2Y |

•Operating •ambient temperature | • -35℃—65℃ |

•Area of net rack | • 10㎡—80㎡ |

•Unit weight | • 200kg——2000kg |

FAQ:

1. How long will my inquiry get response?

Your inquiry related to our products or prices will be replied within 24 hours.

2. Can I get professional service and suggestion?

Well-trained and experienced staffs to answer all your questions in fluent English.

3. Do you accept OEM or customized design?

OEM & ODM, any your customized lightings we can help you to design and put into product.

4. What if I need specific design?

Distributorship are offered for your unique design and some our current models.

- Q:Can a solar mounting system be used in areas with high wind load?

- Yes, a solar mounting system can be used in areas with high wind load. However, it is important to ensure that the mounting system is designed and engineered to withstand the specific wind conditions of the area. This may involve using reinforced materials, strategic placement of the panels, and proper anchoring techniques to ensure the system remains secure and stable during high winds.

- Q:Can solar mounting systems be installed on mobile or temporary structures?

- Yes, solar mounting systems can be installed on mobile or temporary structures. These systems are designed to be versatile and adaptable, allowing them to be mounted on a variety of surfaces including rooftops, ground mounts, and even on mobile structures like trailers or vehicles. This flexibility makes them suitable for use in various temporary applications such as events, construction sites, or emergency response situations.

- Q:Are there any specific requirements for grounding when using a solar mounting system?

- Yes, there are specific requirements for grounding when using a solar mounting system. The National Electrical Code (NEC) mandates that all solar panel systems must be properly grounded to ensure safety and protection against electrical faults. This includes proper grounding of the solar panels, mounting structure, and associated electrical equipment. Grounding typically involves connecting the system to a grounding electrode, such as a grounding rod, to provide a safe path for electrical currents in the event of a fault or lightning strike. Compliance with these grounding requirements is crucial to meet electrical safety standards and prevent potential hazards.

- Q:Are there any specific requirements for installing solar mounting systems in high-temperature regions?

- Yes, there are specific requirements for installing solar mounting systems in high-temperature regions. These include selecting materials that can withstand high temperatures, ensuring proper ventilation and airflow around the panels to prevent overheating, and designing the mounting system to accommodate thermal expansion and contraction. Additionally, it is important to consider the impact of high temperatures on the performance and efficiency of the solar panels.

- Q:Can solar mounting systems be installed on metal roofs?

- Yes, solar mounting systems can be installed on metal roofs. Metal roofs provide a sturdy and durable surface for installing solar panels. Specialized mounting systems designed for metal roofs ensure secure attachment and proper weight distribution, allowing for efficient and safe installation of solar panels.

- Q:Are there different mounting systems for different solar panel sizes?

- Yes, there are different mounting systems available for different solar panel sizes. The size and weight of solar panels vary, so mounting systems are designed to accommodate these variations and ensure proper installation and stability.

- Q:Can a solar mounting system be used with solar trackers?

- Yes, a solar mounting system can be used with solar trackers. In fact, many mounting systems are specifically designed to be compatible with solar trackers. The mounting system provides the necessary support and stability for the solar panels, while the solar trackers allow the panels to follow the sun's movement throughout the day, maximizing their energy output. This combination can greatly enhance the efficiency and performance of a solar power system.

- Q:Can a solar mounting system be used on awnings?

- Yes, a solar mounting system can be used on awnings. Awnings provide a suitable surface for installing solar panels, allowing for efficient utilization of space and harnessing solar energy.

- Q:Can a solar mounting system be used in areas with limited access to sunlight?

- No, a solar mounting system is not suitable for areas with limited access to sunlight as it requires ample sunlight to generate electricity.

- Q:Are there any specific requirements for installing a solar mounting system on a rooftop with snow guards?

- Yes, there are specific requirements for installing a solar mounting system on a rooftop with snow guards. The snow guards should be properly designed and installed to ensure they do not interfere with the solar panels or the mounting system. Additionally, the mounting system should be able to withstand the added weight and stress caused by the presence of snow guards. It is important to consult with a professional installer who can assess the specific rooftop conditions and recommend the appropriate mounting system and snow guard design for optimal performance and safety.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Triangle Single Set Sloped Axis Tracking System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords