Aluminum Frame for Solar Panel/Solar Module

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

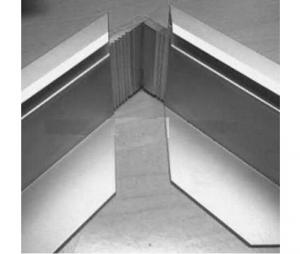

Aluminium frame for solar module.

1)30*25 suitable for 30-120w solar modules

2)50*35 for 160-220w

3)35*35 for 80-180w

A)Features:

1) 30*25 suitable for 30-120w solar modules

2) 35*35 suitable for 80-180w solar modules

3) 50*35 suitable for 160-220w solar modules

4) Many other custom made sizes available, such as 45*35mm, 60*35mm, 46*40mm, 46*50mm, etc.

Common specifications:

1956*992*50mm

1650*992*45mm

1640*992*45mm

1580*808*40mm

1576*808*40mm

1482*670*40mm

1200*545*35mm

754*669*30mm

824*545*30mm

620*286*30mm

(B)Two Types:

1) 90°-Angle

2) 45°-Angle

(C)Surface Treatment:

1) Anodizing (clear, satin, bronze, black, golden, silver, other multicolor)

2) Electrophoresis

3) Powder coating, PVDF, polishing, sand blasting, etc.

Standard: GB/T5237-2004, Q/320281PDW01-2008

Certification: ISO9001, ISO14001, CQM

Specification: According to your design drawings and your samples

Notice:

1. We have all kinds of sizes for the aluminum solar frame, so you need not to pay for the new molds.

2. Our cross sections of aluminum solar frame are very popular in Europe.

3. We can support the aluminum solar module frame according your design drawings and samples, but you have to pay for the new molds, if you are interesting on this, please

contact us in prompt time.

FAQ

Q1:Can we visit your factory?

A1:Sure,welcome at any time,seeing is believing.

Q2:Which payment terms can you accept?

A2:T/T,L/C,Moneygram,Paypal are available for us.

- Q:Are there any specific requirements for the installation of a solar mounting system?

- Yes, there are specific requirements for the installation of a solar mounting system. These requirements vary depending on factors such as the type and size of the solar panels, the location and orientation of the installation site, the local building codes and regulations, and the structural integrity of the roof or ground where the system will be mounted. It is important to consult with a professional installer who can assess these requirements and ensure a safe and efficient installation.

- Q:Can a solar mounting system be used on flat roofs?

- Yes, a solar mounting system can be used on flat roofs. There are specifically designed mounting systems available for flat roofs that allow for the installation of solar panels. These systems typically use ballasts or weight distribution to secure the panels in place without the need for roof penetrations.

- Q:What is the expected increase in property value with a solar mounting system?

- The expected increase in property value with a solar mounting system can vary depending on factors such as the location, size, and efficiency of the system. However, studies have shown that homes with solar panels typically have a higher resale value compared to those without, with estimates ranging from 3% to 20% increase in property value.

- Q:Can a solar mounting system be used in areas with solar incentives for gyms?

- Yes, a solar mounting system can be used in areas with solar incentives for gyms. These incentives are designed to encourage the adoption of renewable energy systems, including solar power. By installing a solar mounting system, gyms can take advantage of these incentives and potentially reduce their energy costs while promoting sustainability.

- Q:What materials are commonly used in solar mounting systems?

- Common materials used in solar mounting systems include aluminum, steel, and stainless steel. These materials are chosen for their durability, strength, and resistance to corrosion, ensuring that the mounting system can withstand various weather conditions and last for a long time. Additionally, some mounting systems may also incorporate plastics or composite materials to provide additional support and flexibility.

- Q:What materials are used in a solar mounting system?

- Some common materials used in a solar mounting system include aluminum, stainless steel, galvanized steel, and various types of plastics.

- Q:Can a solar mounting system be used in areas with solar incentives for universities?

- Yes, a solar mounting system can be used in areas with solar incentives for universities. These incentives are designed to promote the adoption of solar energy and encourage renewable energy initiatives. By installing a solar mounting system, universities can benefit from these incentives, such as tax credits, grants, or feed-in tariffs, which can help offset the initial installation costs and provide long-term financial savings. Additionally, using solar energy aligns with the sustainability goals of universities, demonstrating their commitment to reducing carbon emissions and promoting environmental stewardship.

- Q:Are there any specific requirements for facade or cladding design when using a solar mounting system?

- Yes, there are specific requirements for facade or cladding design when using a solar mounting system. The design should consider the weight and load-bearing capacity of the facade or cladding to ensure it can support the added weight of the solar panels and mounting system. Additionally, the design should allow for proper ventilation and air circulation to prevent overheating of the solar panels. It is also important to consider the aesthetic integration of the solar panels with the facade or cladding to maintain the overall visual appeal of the building.

- Q:Can a solar mounting system be used in areas with solar incentives for wineries?

- Yes, a solar mounting system can definitely be used in areas with solar incentives for wineries. In fact, it is highly recommended to take advantage of these incentives as they can greatly offset the cost of installing and operating a solar power system. By installing a solar mounting system, wineries can harness the power of the sun to generate clean and sustainable energy, reducing their reliance on traditional energy sources and potentially saving on electricity bills. Additionally, by utilizing solar incentives, wineries can make their investment in solar power even more financially feasible and attractive.

- Q:Can a solar mounting system be installed on a condominium or apartment complex?

- Yes, a solar mounting system can be installed on a condominium or apartment complex. However, it is important to consider factors such as the structural integrity of the building, available roof space, and any local regulations or restrictions that may be in place. Additionally, the ownership structure of the building and the willingness of all residents to participate in the installation and maintenance of the system should also be taken into account.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Frame for Solar Panel/Solar Module

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords