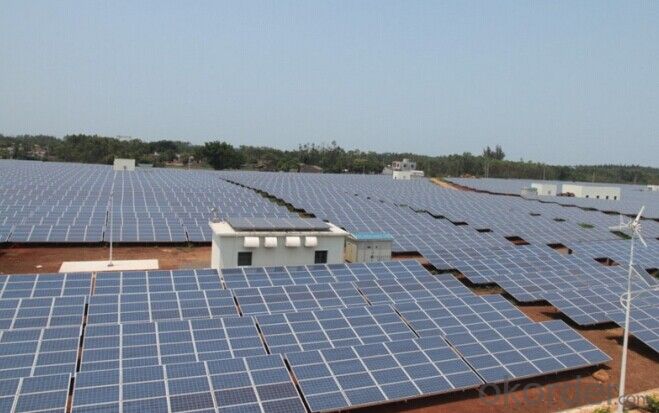

Polycrystalline Dual-axis Tracking System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products introduction:

Polycrystalline dual-axis tracking system is high-tech petented product.

Y-axis adopt eccentric driving.power generating can be increased more then 40%.

The tracker bracket adopt hot-dipped galvanizde high-quality structual steel Q235B,system stability is very high and maintenance cost is very low,working time more than 25years.

Features:

1. The system, which uses an isosceles triangle bracket as bracket structure and maintenance-free, wind and sand-proof high polymer material bearing moving parts and unique linkage structure, features reliable system stability, low cost and low failure rates.

2. Compared with traditional fixed-bracket its annual energy output can be increased up to approximately 20 percent - 30 percent.

3. With exactly the same or even lower cost as fixed-bracket the system is the optimal choice for the establishment of large and medium-sized high-efficiency solar power stations.

Specification:

• Installed capacity | • 2KW—20KW |

• control method | • light control • time control • light/time control |

• Tracking accuracy | • ≤0.1° |

• Track elevation | • 0—75° |

• Tracking azimuth | • 245° |

• The safe operation of wind speed • | • 75km/h |

• Maximum wind resistance | • 150km/h |

• Drive type | • Rotary gear drive |

• Driving motor power | • DC24V/30W—100W |

• Structural materials | • Q235 Hot dip galvanized steel |

• Protection grade • | • I P 6 5 |

• Service / warranty • | • 25Y/2Y |

• Working environment temperature | • -35℃—65℃ |

• Net area | • 10㎡—120㎡ |

•The weight of the system | • 500kg—3000kg |

- Q:Can a solar mounting system be used in areas with solar incentives for seaports?

- Yes, a solar mounting system can be used in areas with solar incentives for seaports. These incentives encourage the adoption of renewable energy, including solar power, in seaport areas. By installing a solar mounting system, seaports can take advantage of these incentives to reduce their carbon footprint, lower energy costs, and contribute to a more sustainable energy future.

- Q:Can a solar mounting system be installed on a rooftop with a gravel stop roof?

- Yes, a solar mounting system can be installed on a rooftop with a gravel stop roof. The mounting system can be designed and installed in a way that accommodates the presence of a gravel stop roof, ensuring a secure and functional installation.

- Q:Can a solar mounting system be used for solar streetlights or outdoor lighting?

- Yes, a solar mounting system can be used for solar streetlights or outdoor lighting. Solar mounting systems are designed to securely hold solar panels in place, allowing them to absorb maximum sunlight and convert it into electricity. This electricity can then be used to power streetlights or outdoor lighting systems, providing a sustainable and renewable energy source for outdoor illumination.

- Q:Are there any shading considerations when choosing a solar mounting system?

- Yes, there are shading considerations when choosing a solar mounting system. Shading can significantly reduce the efficiency and overall output of a solar system, so it is important to select a mounting system that minimizes shading and allows for optimal sunlight exposure.

- Q:Are there any specific requirements for awning or sunshade design when using a solar mounting system?

- Yes, there are specific requirements for awning or sunshade design when using a solar mounting system. These requirements typically include ensuring that the awning or sunshade does not obstruct the sunlight from reaching the solar panels, maintaining proper clearance between the awning/sunshade and the solar panels to allow for ventilation and prevent overheating, and ensuring the structural integrity of the awning/sunshade to withstand the additional weight of the solar panels. Additionally, it is important to consider the angle and orientation of the solar panels in relation to the awning/sunshade to optimize energy generation.

- Q:Can a solar mounting system be installed on a rooftop with a flat metal roof?

- Yes, a solar mounting system can be installed on a rooftop with a flat metal roof. There are specially designed mounting systems available that are compatible with flat metal roofs. These systems typically use brackets or clamps to secure the solar panels to the roof without compromising its integrity.

- Q:Can a solar mounting system be used with solar tracking technology?

- Yes, a solar mounting system can be used with solar tracking technology. In fact, a solar tracking system can enhance the efficiency of a solar panel by automatically adjusting its position to follow the sun's movement throughout the day. This can optimize the amount of sunlight the panel receives, maximizing its energy output.

- Q:Can a solar mounting system be used with solar-powered RVs?

- Yes, a solar mounting system can be used with solar-powered RVs. A solar mounting system provides a secure and efficient way to install solar panels on the roof of an RV, allowing for the harnessing of solar energy to power various appliances and systems within the vehicle.

- Q:How do you choose the right solar mounting system for your project?

- To choose the right solar mounting system for your project, it is essential to consider several factors. Firstly, assess the type and size of your solar panels, as well as the weight they will impose on the mounting system. Additionally, evaluate the specific requirements of your project, such as the available space, environmental conditions, and local regulations. Consider the type of mounting system that suits your needs, whether it is rooftop, ground-mounted, or tracking. It is also crucial to research and compare different mounting system manufacturers, considering their reputation, reliability, and warranty options. Finally, consult with professionals or experts in the solar industry to ensure you make an informed decision that aligns with your project goals and budget.

- Q:Can a solar mounting system be installed on a condominium or apartment complex?

- Yes, a solar mounting system can be installed on a condominium or apartment complex. However, it is important to consider factors such as the structural integrity of the building, available roof space, and any local regulations or restrictions that may be in place. Additionally, the ownership structure of the building and the willingness of all residents to participate in the installation and maintenance of the system should also be taken into account.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polycrystalline Dual-axis Tracking System

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 watt

- Supply Capability:

- 5000000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords