The Curtain Wall Gasket for Building

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 20000 Sets Per Week set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of The Curtain Wall Gasket For Building

1.material:EPDM Rubber,PVC

2.speciality:ani-aging,acid,water resistence

3.OEM

4.meet GB/T 24498-2009

5.short lead time

Specifications of The Curtain Wall Gasket For Building

1.material:EPDM Rubber,PVC

2.speciality:ani-aging,acid,water resistence

3.OEM

4.meet GB/T 24498-2009

5.short lead time

Features of The Curtain Wall Gasket For Building

Good aging resistance: The aging resistance of EPDM is as well as the Silicone rubber.

Good comprehensive physical mechanical resistance: It shows excellent performance especially the Static Sealing and Dynamic Sealing.

Good corrosion resistance.

Good flexibility : Meet the GB12002-89 standard perfectly.

Good elasticity.

Convenient installation

Competitive price and prompt delivery.

According to customers’ design.

Technical Specifications of The Curtain Wall Gasket For Building

Material: | EPDM,PVC |

Type: | As customers' design |

Producing way: | Extrusion |

Hardness: | 45~75shore |

Color:

| Black,Grey,White or according to customers’ requirements |

Temperature: | -40~+150°C |

Craft: | Best Microwave Vulcanizating |

Packaging: | Woven bag, Carton or according to customers’ requirements |

Function: | For window,door,auto,etc |

Raw material We dedicated to producing good quality products with quality raw material. We import material for EPDM from Holland-DSM,USA-ROYALENE and Dupon,Japan-Mitsui,Germany-Bayer Ag etc.

Production Range of The Curtain Wall Gasket For Building

EPDM/NBR/Silicone/PVC Rubber Seal

EPDM extrusion profile/extrusion side profile

Auto/Car/trunk seal

Door &Window seal

Garage door sealing strip

Silicone seal strip

- Q:Tempered glass can not be broken by a few millimeters

- 8mm above the thickness of the tempered glass can stand, as long as not deliberately hard step, is very strong. I hope my answer can help you, hope to adopt!

- Q:What is the difference between steel and glass walls?

- 1, from the architectural point of view, completely different things. One is the whole house; one is the building facade. 2, from the relatively rigorous professional qualification point of view, is the scope of the work of different qualifications. One is steel professional; one is curtain wall professional. 3, from the construction point of view, the two are almost the same thing. One is the steel structure of the glass, one is the steel structure for the skeleton of the curtain wall surrounded by the house.

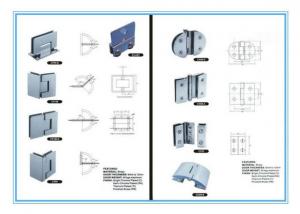

- Q:How is the glass curtain wall attached to the steel frame fixed on the steel frame

- Steel structure point curtain wall cylindrical adapter seat welded to the steel structure, the splicing claw screw to the adapter seat, the joint and then fixed to the splicing claw

- Q:What is the between glass and steel frame?

- There is a thing called the splicing claws, or to tough accessories to ask, they have a frameless curtain wall accessories

- Q:Curtain wall panel installation control points which

- The splicing jaws serve as an important accessory to the glass curtain wall, which plays an important role in the connection of the glass curtain wall. The mechanical properties are particularly important by passing the load to the steel structure or other body structure through the splice joint. Of the installation staff, in the point of the installation of the curtain wall accessories need to master more technical and knowledge points. Introduction is the stainless steel splicing jaws when you need to pay attention to the installation of some of the details, hoping to help everyone. The stainless steel splicing pawl-type curtain wall fittings are composed of splice joints, splicing claws, adapter parts and so on. The splicing jaws are mainly used as supporting link joints and pass the load to the fixed supporting structure system, which is connected with the glass curtain wall An important accessory. With the impact of the curtain wall industry, in order to achieve the best effect of the use of stainless steel splicing claws, construction details are essential, and today to introduce some of the details of the construction of the splicing claws and the need to pay attention to the problem. The first is the preparation before the installation.

- Q:Stainless steel splicing claws attached to what steel structure above

- Splicing jaw pieces alias glass claws, split jaws mainly as a support link joints, and transfer load to the fixed support structure of the system, is to connect the glass curtain wall is an important accessories.

- Q:304 stainless steel splicing claws the price is how much, what quality and cheap manufacturers

- 304 stainless steel splicing claw is not expensive, if the amount of large manufacturers suggested that the cooperation, 304 material cost-effective, widely used.

- Q:What is the size of the glass I use

- Light steel glass canopy focus on just the material for the light steel, tempered glass rain shed focus on the glass material for the tempered glass, are glass canopy

- Q:The difference between the skeleton curtain wall and the whole glass curtain wall

- 1, with a skeleton curtain wall is common aluminum frame, glass inlaid or attached to the keel. Common hidden frame and the box in two ways. 2, the whole glass curtain wall refers to the splicing jaw type of glass installation, the skeleton is the steel structure, glass and skeleton is in two levels.

- Q:What are the accessories of the point-supported glass curtain wall?

- Point-type glass curtain wall accessories are stainless steel curtain wall adapter, split joints, split claws, glass clip, handrail pieces, rain canopy accessories, support rods, rods, cable, stainless steel mini cable and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO 9001:2000;ISO 9001:2008;QS-System nach EN 764-5, Abschnitt 4.2, und AD 2000-Merkblatt W O |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

The Curtain Wall Gasket for Building

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Sets set

- Supply Capability:

- 20000 Sets Per Week set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords