Stainless Steel Wire Rope/Rod

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Miles m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Dia.: 0.28mm-30.0mm

Type: Stainless Steel Wire Rope

Corlstruction:1×7, 1×19, 1×37, 7×7, 6×7+IWS, 6×19+IWS, 7×37, 19×7, 6×19S+FC, 6×19S+IWRC,6×19W, 6×25Fi, 6×26WS, 6×31WS, 8×19S, 8×19W, 8×25Fi, 8×26SW etc.

1 | Product Name | Stainless Steel Wire Rope |

2 | Brand | |

3 | Grade | 201, 202, 301, 302, 304, 304L, 316, 316L etc. |

4 | Corlstruction | 1×7, 1×19, 1×37, 7×7, 6×7+IWS, 6×19+IWS, 7×37, 19×7, 6×19S+FC, 6×19S+IWRC,6×19W, 6×25Fi, 6×26WS, 6×31WS, 8×19S, 8×19W, 8×25Fi, 8×26SW etc. |

5 | Standard | EN12385-4(DIN3055) |

6 | Dia. | 0.28mm-30.0mm |

7 | Length | 1525m/reel, 1000m/reel, 500m/reel, 305m/reel, etc. |

8 | Tensile strength | >1600N/mm² |

9 | MOQ | 1000m |

10 | Packing | inner Packing: Wooden or plastic spools and craft paper Outer Packing: Strong wooden pallet or according to requests |

11 | Application | stainless steel wire ropes are widely supplied to areas of machine-made industry, shipping industry, architecture, elevator, household products etc. |

12 | Delivery time | 15-30 days after receiving the full payment |

13 | Service | 1.Professional engineer advices |

2.Product Warranty is offered | ||

3.OEM, ODM , Customer design | ||

14 | Payment | L/C, T/T |

15 | Ability | 500Ton/month |

Our Advantage:

Our product has a good ductility, high tensile strength and can be last long in use. High flexibility, abrasion resistance and corrosion resistance, unified diameter, smooth surface, bright color, etc. Especially the electrolysis bright wire, it’s our “hot sales” product since the surface and quality will give you a satisfactory answer.

Instruction:

The non-rust of the stainless steel means it can have certain chemical stability around the corrosion mediums of air, water, acid, alkali, salt or others. But it does not mean the stainless steel will never rust. Whether the stainless steel will rust or not is influenced by the molecular structures, the processing technic, and the operating environment and so on. To prevent the stainless steel from rusting extremely, please pay attention to the followings:

After many years, we can:

Own design - meet the project needs;

Own production - ensure that the project in a timely manner;

Rigorous testing - ensure good quality;

Dedication to service - ensure customer’s satisfaction;

The whole management - ensure Honor.

- Q:What is the point of the ribbed curtain wall

- Point refers to the point of the type, the glass panel is fixed by the stainless steel dial system; rib dial refers to the dial system is fixed in the rear of the panel on the floor. The most common is the glass ribs point of the curtain wall.

- Q:How is the glass curtain wall attached to the steel frame fixed on the steel frame

- Steel structure point curtain wall cylindrical adapter seat welded to the steel structure, the splicing claw screw to the adapter seat, the joint and then fixed to the splicing claw

- Q:Afraid to stand under the building with a glass curtain wall Today to the digital square, walked, suddenly heard a sound, and then a look at the front of the meter on the second floor of the glass split on the second floor, just under the two people passing. A time screaming again and again. Sent to the nearby hospital, blood flow all the way ... ... I also decorated the company for two years, really do not understand why so many people like glass curtain wall now. Personally feel that it can only look at the top, but also unsafe (old in the accident), and dirty (high difficult to clean up).

- Now people like simple, and the light is very good, you can save energy, if it is the wall, then how much to waste electricity Although he has light pollution, but still like

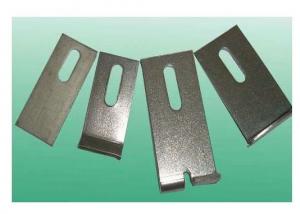

- Q:What are the skeleton of the glass curtain wall system

- Pendant glass curtain wall This is the use of four-jaw stainless steel pendant with the column welding, pendant of each claw with a glass of a hole connected to the two pendant at the same time with four glass connected, or a piece of glass fixed on the four pendant. Four holes drill holes.

- Q:Curtain wall decoration line junction how to take a good connection

- With a strong bond strength, crack resistance, anti-hanging, freeze-thaw resistance, waterproof and other effects. Easy to use.

- Q:Point glass curtain wall is the main material or auxiliary material? What is the basis?

- The budget quota does not have its subdivision of the unit price, and the description of it, nor on its labor costs, mechanical expenses and other composition analysis.

- Q:Stainless steel splicing claws attached to what steel structure above

- Splicing jaw pieces alias glass claws, split jaws mainly as a support link joints, and transfer load to the fixed support structure of the system, is to connect the glass curtain wall is an important accessories.

- Q:304 stainless steel splicing claws the price is how much, what quality and cheap manufacturers

- Also depends on what size you want. Prices in the tens to hundreds of range. Last month, our company set a number of split claws, manufacturers called Jiangsu Jie Chen, dozens of dollars a set, okay, no rust.

- Q:Glass curtain wall connector (including the base, split joints, split jaws) how much money a set of prices

- Brand a lot of price difference is great, can call the dealer.

- Q:Will the glass curtain wall, 1600 * 2500 glass, 8 +8 glued rubber, with more of the appropriate claw claw, more than 60 meters of the building, so much glass stress enough?

- If it is above the canopy, the general series, such as 220,250 series or even 300 paw pieces are enough, light If it is a facade curtain wall, then it is recommended that you choose the type of heavy-duty claw pieces, remember that the weight of the claw determines the load-bearing, while the corresponding joints to improve the proposed tough or imitation type weight, such as 250 Series of four claws 2.2-2.4kg pure jaw pieces

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 2009 |

| Annual Output Value | Above US$1 million |

| Main Markets | Asia, Middle East,America |

| Company Certifications | CE, CCC, ISO90001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.3 |

| No.of Employees in Trade Department | 4 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Lower |

Send your message to us

Stainless Steel Wire Rope/Rod

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Miles m.t.

- Supply Capability:

- 500 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords