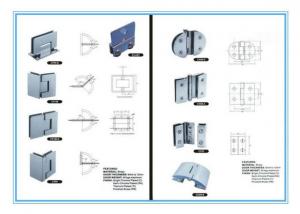

Stainless Steel Glass Clamp of Building Hardware with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1200 Pieces Per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of The Stainless Steel Glass Clamp Of Building Hardware With High Quality

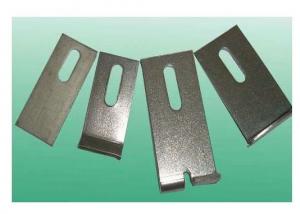

1,Material: Stainless Steel

2,Usage: Glass Clamp forbuilding

3,Standard or Nonstandard: Standard

4,size and thickness:custom

1. Main specifications of The Stainless Steel Glass Clamp Of Building Hardware With High Quality

Process | Lost wax casting(Silica method) |

Key specification |

1.Material: stainless steel 304 316 316L

2.Standard: ASTM\DIN\BS\JIS

3.Surface finish: stain polished or mirror polished

4.Weight: about 200-300grams

5.Useful: 8-20mm width glass |

production facility | 1.Casting facility: wax injector, paint mixer, medium-frequency induction furnace, box resistance furnace, cutting head machine, shot-blasting machine, sand-blasting machine, pickling line. 2.Machining facility: CNC machine, linear cutting machine, NC milling machine, polishing machine. |

Heat treatment | Solid solution. |

Testing facility | spectrometer, tensile test machine, hardness test machine, mircoscope. |

2.About The Stainless Steel Glass Clamp Of Building Hardware With High Quality

(1)We can produce your goods according to your drawings, also can do complicated products.

(2)We can do CNC machining and many kinds surface treatment, just tell me your requirements on physical properties.

3. About quality of The Stainless Steel Glass Clamp Of Building Hardware With High Quality

1)Our products are tested by spectrometer before pouring, so just forget the material requirements.

2)Our spectrometer is introduced from Germany in 2007.

3)Our workers test each piece before store it.

4.About Factory

(1)Experience:We have 16 years experience in casting and take the lead in passing ISO9001:2000 among the same industry.

(2)Good After Sales Service:We have advanced facilities to guarantee our product's quality and any small problem happening of our products will be solved at the most prompt time.

5.Our market:

Popular in the Europe and America, also in Janpan and South Korea.

- Q:What is the point of the ribbed curtain wall

- Is the whole glass curtain wall + split claws

- Q:What is the between glass and steel frame?

- Foam double-sided adhesive paste separated, both sides of the glass glue.

- Q:What is the use of borehole during the production of tempered glass?

- Drilling, opening is to meet the actual needs of the installation of glass, such as the installation of glass curtain wall need to open the claw hole, the installation of the glass door need to open the door clip, the handle hole, etc .; there are some special locations in order to open the obstacles Objects, such as beams, corners, etc., but also to maintain the overall appearance of the case, need to be punched on the glass, open missing.

- Q:The installation method of the splicing jaws

- Steel beams and glass are ready to ensure that the location is not wrong, as well as glass holes, adapter and steel beam welding no problem. Put the claws on the transfer, engage in tight. Put the splice on the glass, engage in tight, do not forget the middle of the gasket. Then, the glass is mounted, the splice is connected with the splicing jaws, but do not twist too tightly, and then adjust the position and adjust the error. Finally, tighten, check the next to ensure safety. Ordinary is so loaded, of course, there are different styles, installation methods are different, but not difficult.

- Q:Curtain wall decoration line junction how to take a good connection

- AFA Binders are architectural adhesives for unique formulations of OKorder Eau De Toilette Decoration Engineering Co., Ltd. (formerly Alfa Wall Decoration Engineering Co., Ltd.).

- Q:Point glass curtain wall is the main material or auxiliary material? What is the basis?

- The budget quota does not have its subdivision of the unit price, and the description of it, nor on its labor costs, mechanical expenses and other composition analysis.

- Q:Stainless steel splicing claws attached to what steel structure above

- Splicing jaw pieces alias glass claws, split jaws mainly as a support link joints, and transfer load to the fixed support structure of the system, is to connect the glass curtain wall is an important accessories.

- Q:304 stainless steel splicing claws the price is how much, what quality and cheap manufacturers

- Also depends on what size you want. Prices in the tens to hundreds of range. Last month, our company set a number of split claws, manufacturers called Jiangsu Jie Chen, dozens of dollars a set, okay, no rust.

- Q:Is there a stainless steel splicing claw with the same price but cheaper manufacturers?

- Some, a lot of It's harder to find than it is.

- Q:What are the accessories of the point-supported glass curtain wall?

- Mainly to connect joints, splicing claws, adapter, fixture, support rod, cable, rod, etc., what difficulties can say ah, I can help you solve the initial ah

1. Manufacturer Overview |

|

|---|---|

| Location | Shanghai,China |

| Year Established | 2003 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Western Europe Northern Europe |

| Company Certifications | IS09001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Stainless Steel Glass Clamp of Building Hardware with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Pieces pc

- Supply Capability:

- 1200 Pieces Per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords